Polyurethane black smooth-faced hammer paint and preparation technology thereof

A technology of polyurethane poly black and cotton paint, applied in the field of polyurethane poly black cotton paint and its preparation technology, can solve the problems of unsightly appearance, uneven texture, poor weather resistance of the coating, etc. Brightness, texture uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

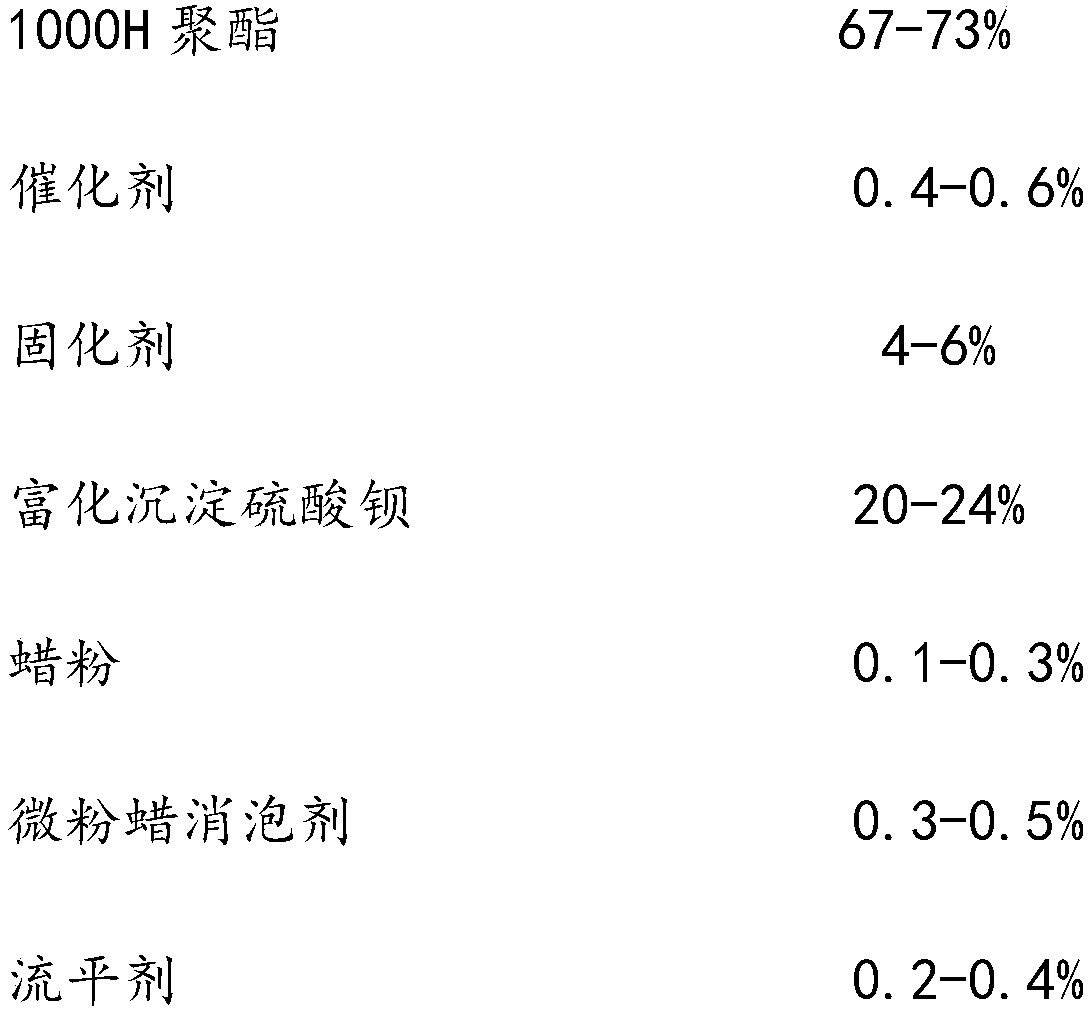

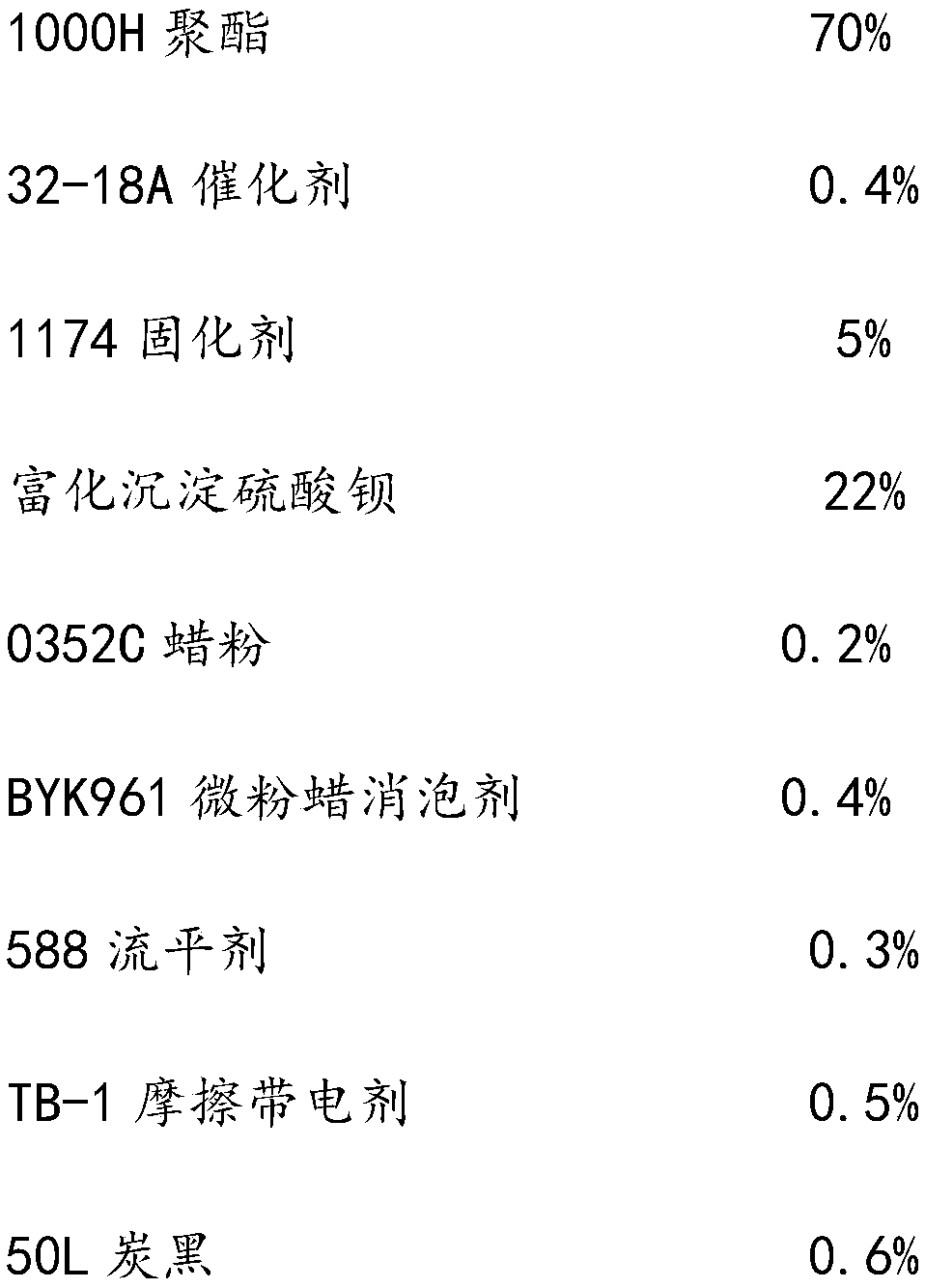

[0027] The present invention relates to a kind of polyurethane poly black cotton paint, and its composition content is:

[0028]

[0029]

[0030] Preferably, the 32-18A catalyst is an amine-blocked sulfonic acid catalyst.

[0031] Preferably, the 1174 curing agent is tetramethoxyglycolic resin.

[0032] A kind of preparation technology of polyurethane black cotton paint, its steps are as follows:

[0033] Step 1, prepare raw materials in proportion;

[0034] Step 2, put the prepared raw materials into the mixing bowl and mix evenly;

[0035] Step 3: Proofing, debugging, testing and checking the mixed material in Step 2;

[0036] Step 4, put the ingredients checked in step 3 into the extruder for extrusion, tableting and fragmentation;

[0037] Step 5, put the fragments made in step 4 into a pulverizer for crushing and grading and sieving;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com