Copper pipe annealing system

A copper tube and annealing technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as waste of nitrogen, difficulty in accurately controlling the amount of nitrogen, and reduced resource utilization, so as to ensure quality, improve resource utilization, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

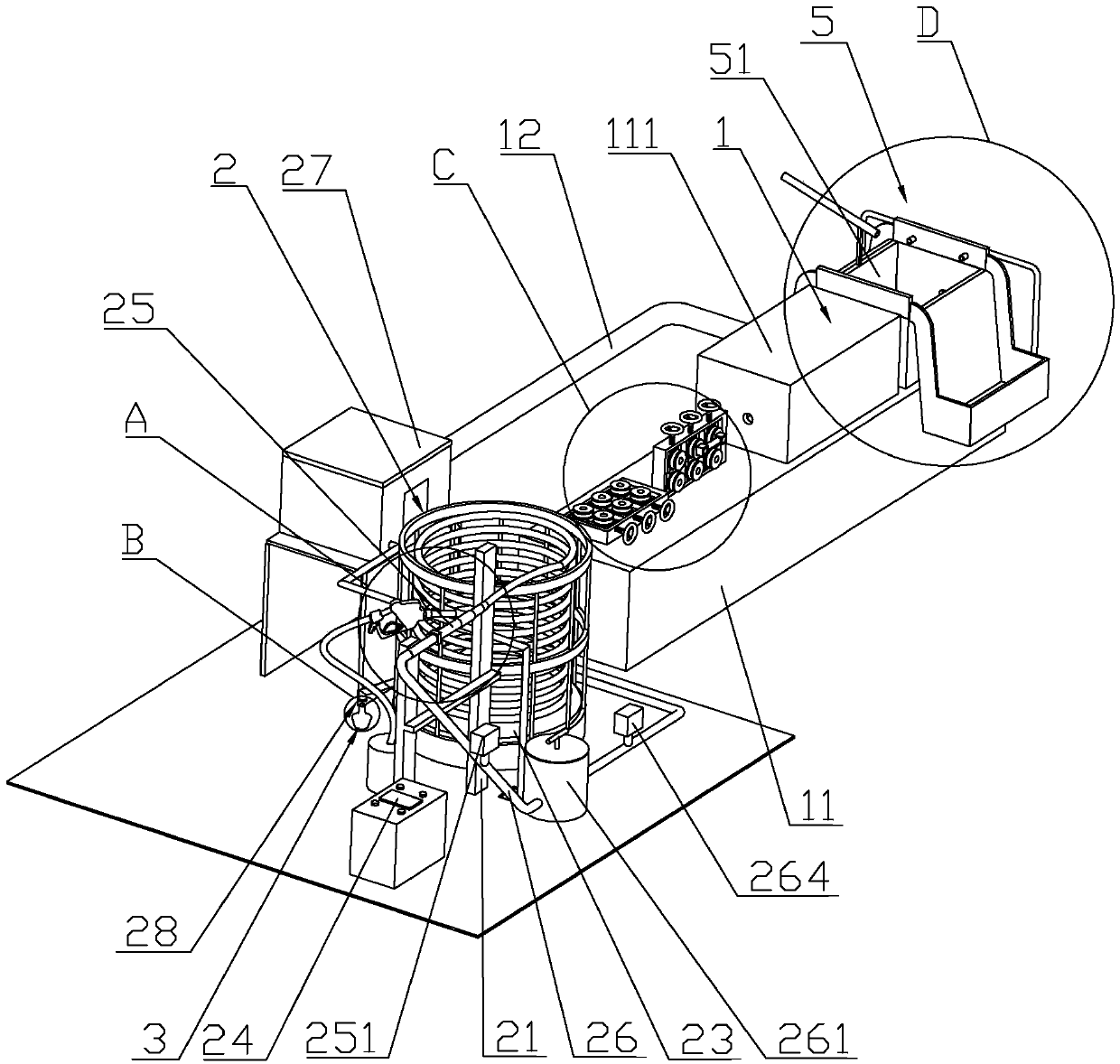

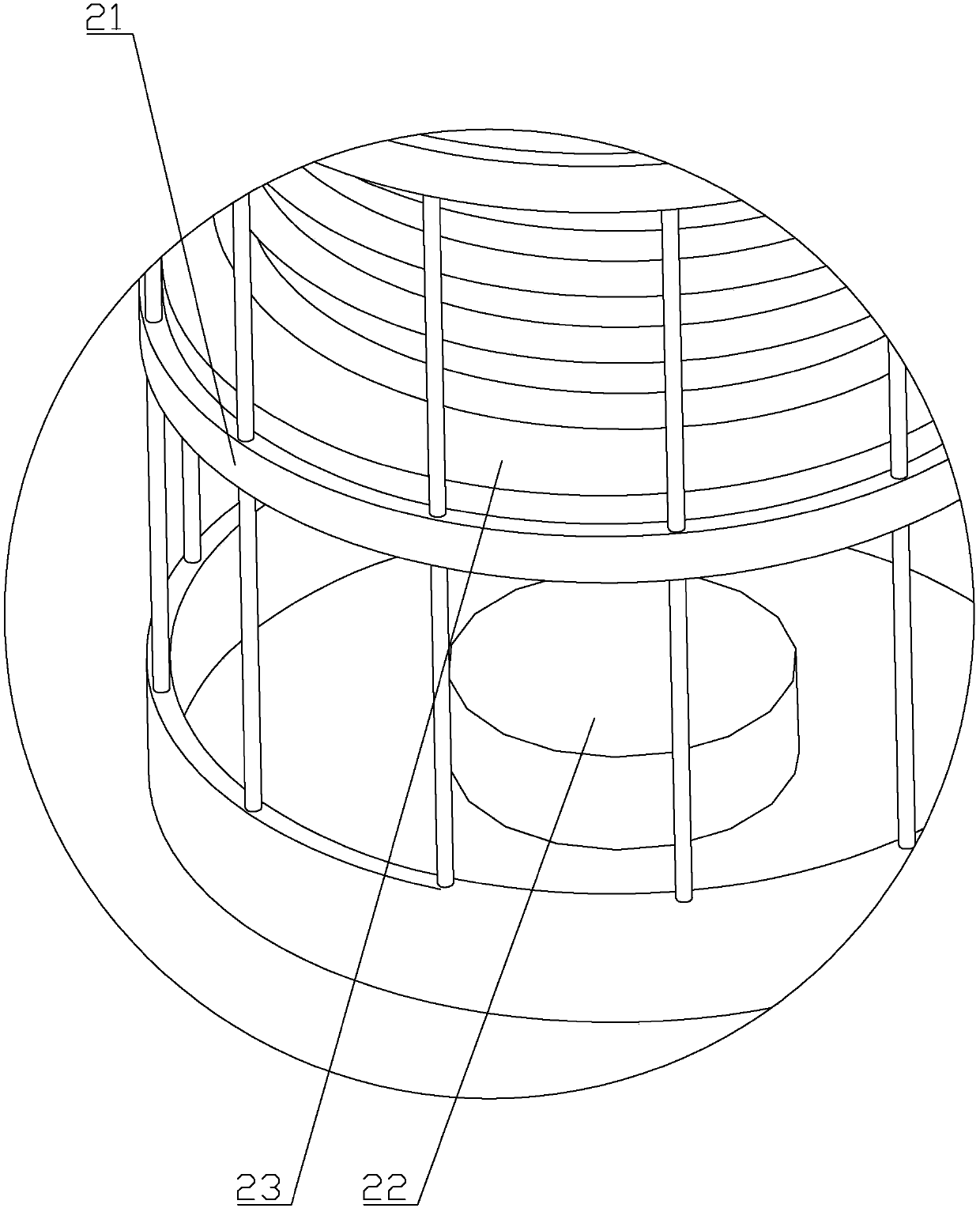

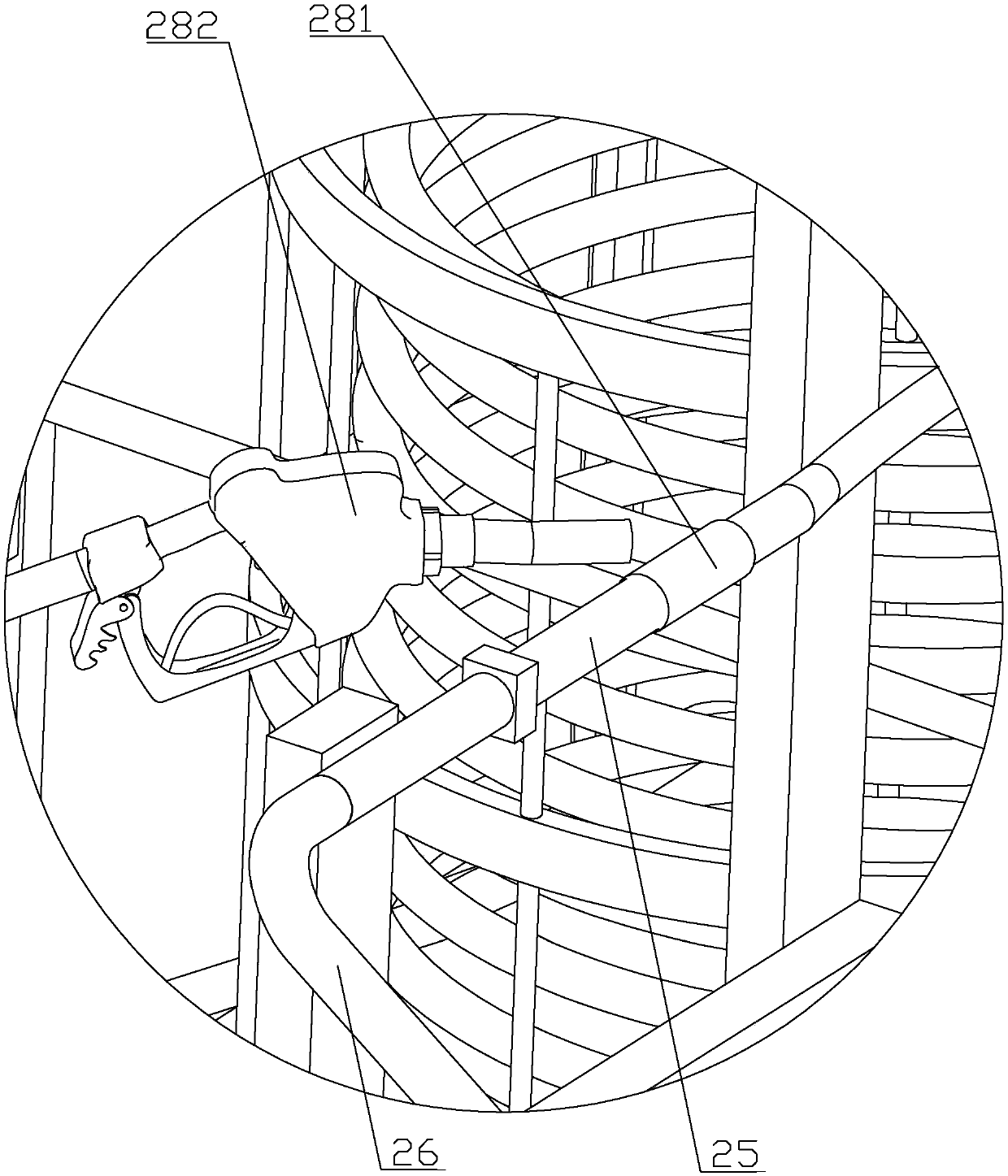

[0042] refer to figure 1 , is a copper tube annealing system disclosed in the present invention, comprising an annealing device 1, a nitrogen filling device 2 arranged on the feed side of the annealing device 1, a detection mechanism 3 connected to the copper tube for detecting the nitrogen filling state, and The driving copper pipe connected to the annealing device 1 passes through the nitrogen filling device 2 and the driving member of the annealing device 1 . Nitrogen filling device 2 injects nitrogen gas into the copper tube, so that the copper tube is in an anaerobic state, so as to avoid the oxidation phenomenon on the inner wall of the copper tube when the copper tube is subjected to high temperature treatment in the annealing device 1 and reduce the quality of the copper tube. The detection mechanism 3 is used It is used to detect whether the nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com