Device and method for reducing powder content of lump ore

A technology of powder ratio and lump ore, applied in the field of blast furnace ironmaking, can solve the problems of reducing the powder ratio of lump ore, high lump ore powder ratio, difficulty in screening, etc., so as to reduce the powder ratio of lump ore and improve screening. Efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

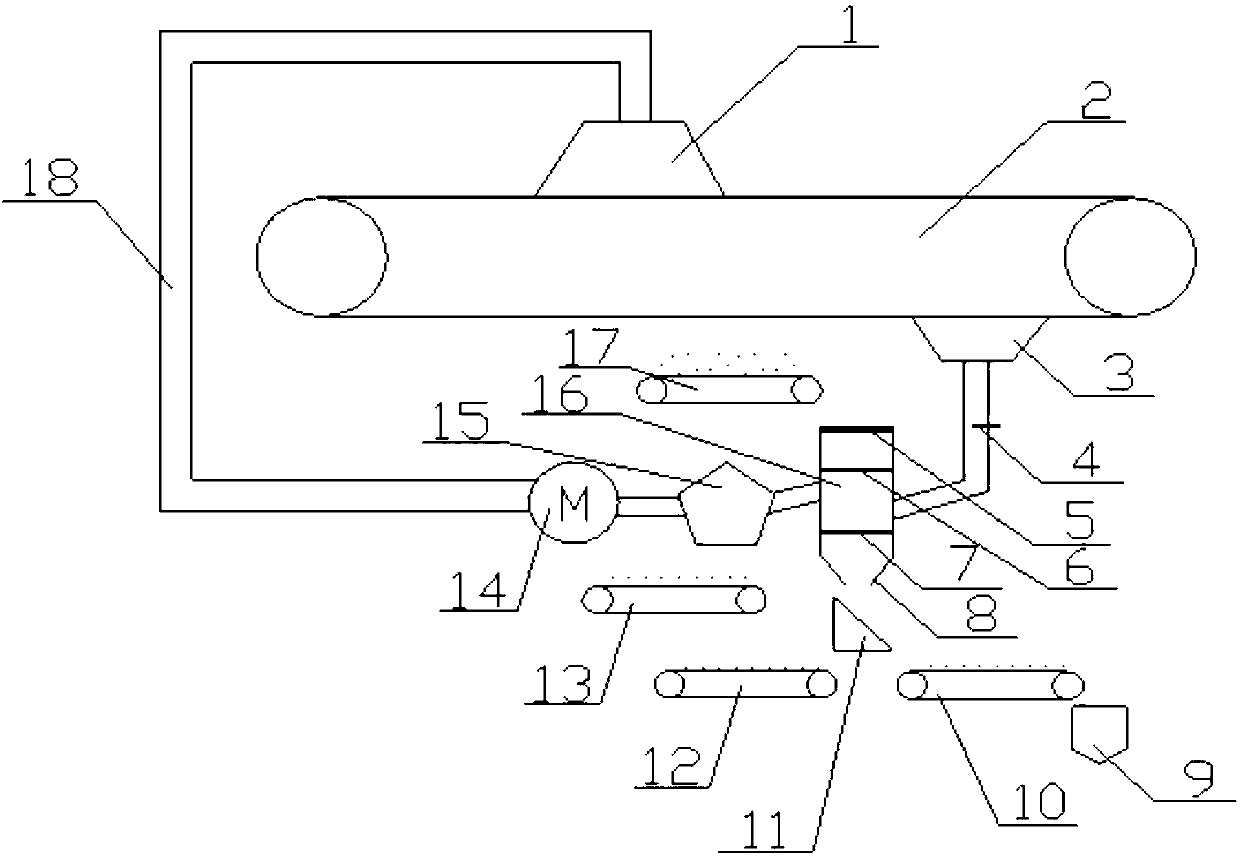

[0035] Example 1, taking a sintering machine in a steel factory as an example, the induced draft fan used in the system is SJ1800, the electrostatic precipitator is HHD-30 / 3 / 1, the belt conveyor is SJ20, the vibrating screen is GFS, and the electric plate The valve is ZQ type, all of which are free equipment, and the fume hood, oven, pipeline and silo are made of 304 stainless steel.

[0036] The sintering machine has a total of 22 bellows, and the flue gas from the bellows at 7 / 10-4 / 5, that is, the bellows No. 16 and 17, is extracted for use. The temperature of the flue gas is about 320°C; the area of the bellows is 1.5m 2 , the width of the trolley is 4m, and the area of the fume hood is 6m 2 , with a width of 4m and a length of 1.5m. The amount of lump ore used in the blast furnace matched with the sintering machine is 15.6t / h, and the powder content of the lump ore is 20%. The designed baking furnace bakes 9.8t of lump ore every 30 minutes. The included angle with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com