Cyanide-free gold plating technology after nickel plating and priming of electronic component

A technology of cyanide-free gold plating for electronic components, which is applied in the technical field of cyanide-free gold plating of electronic components after nickel-plating as a primer, can solve the problems of difficult to meet the requirements of coating performance, poor gold-plating binding force, etc., to reduce the number of solution replenishment, Improved productivity and wide range of ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

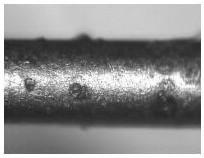

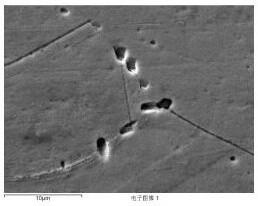

Image

Examples

Embodiment 1

[0050] A cyanide-free gold-plating process for electronic components after nickel-plating and bottoming, comprising the following steps:

[0051] ① Take electronic components, soak them in 30% hydrochloric acid, rinse with tap water for 45s, clean, and chemically polish for 3min at room temperature. Soak in 12% sodium bicarbonate solution for 15s to neutralize, rinse with tap water for 45s, shake off excess water, soak in distilled alcohol for 12s, and dry at 100-110°C for 30min;

[0052] ②Clamp the electrical components treated in step ① to a conductive fixture, clean with tap water for 45s, and deoil by electrolysis. The deoiling by electrolysis is; 2 , temperature 60-80 ℃, forward time 2min, reverse time 1min, followed by 80-90 ℃ hot water cleaning for 45s, tap water for 3 times;

[0053] ③ Soak the electrical components treated in step ② with 18% analytical pure hydrochloric acid for 12s, move left and right up and down during soaking, and then clean with deionized water ...

Embodiment 2

[0061] A cyanide-free gold-plating process for electronic components after nickel-plating and bottoming, comprising the following steps:

[0062] ① Take electronic components, soak them in 30% hydrochloric acid, rinse them with tap water for 60s, clean them, and chemically polish them for 3min at room temperature. Soak in 15% sodium bicarbonate solution for 20s to neutralize, rinse with tap water for 60s, shake off excess water, soak in distilled alcohol for 15s, and dry at 100-110°C for 35min;

[0063] ②Clamp the electrical components treated in step ① to a conductive fixture, clean with tap water for 60s, and deoil by electrolysis. The deoiling by electrolysis is; 2 , temperature 60-80 ℃, forward time 2min, reverse time 1min, followed by 80-90 ℃ hot water cleaning for 60s, tap water for 5 times;

[0064] ③ Soak the electrical components treated in step ② with 20% analytical pure hydrochloric acid for 15s, move left and right up and down during soaking, and then clean with d...

Embodiment 3

[0072] A cyanide-free gold-plating process for electronic components after nickel-plating and bottoming, comprising the following steps:

[0073]① Take electronic components, soak them in 30% hydrochloric acid, rinse with tap water for 30s, clean, and chemically polish for 2min at room temperature. Soak in 10%% sodium bicarbonate solution for 10s to neutralize, rinse with tap water for 30s, shake off excess water, soak in distilled alcohol for 10s, and dry at 100-110℃ for 25min;

[0074] ②Clamp the electrical components treated in step ① to a conductive fixture, rinse with tap water for 30s, and deoil by electrolysis. The deoiling by electrolysis is; 2 , temperature 60-80 ℃, forward time 2min, reverse time 1min, followed by 80-90 ℃ hot water cleaning for 30s, tap water cleaning 2 times;

[0075] ③ Soak the electrical components treated in step ② with 15% analytical pure hydrochloric acid for 10s, move left and right up and down during soaking, and then clean with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com