Processing method of terylene irregular drafting silk fabric

A processing method and irregular technology, applied in rayon manufacturing, hollow filament manufacturing, filament/thread forming, etc., can solve the problem that the combination performance of polyester finishing agent and polyester fiber is not ideal, the fiber cannot be tightly combined, and the fiber is modified. General effect and other problems, to achieve the effect of improving air permeability and hydrophilicity, stable structure, and suitable for wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the finishing agent is: dissolving silk fibroin in deionized water to obtain a silk fibroin solution, then dissolving chitosan oligosaccharide in the silk fibroin solution, and then adding polyethylene glycol-8000, citric acid and Disodium hydrogen phosphate, add deionized water to a total of 100 parts, stir well, ready to use.

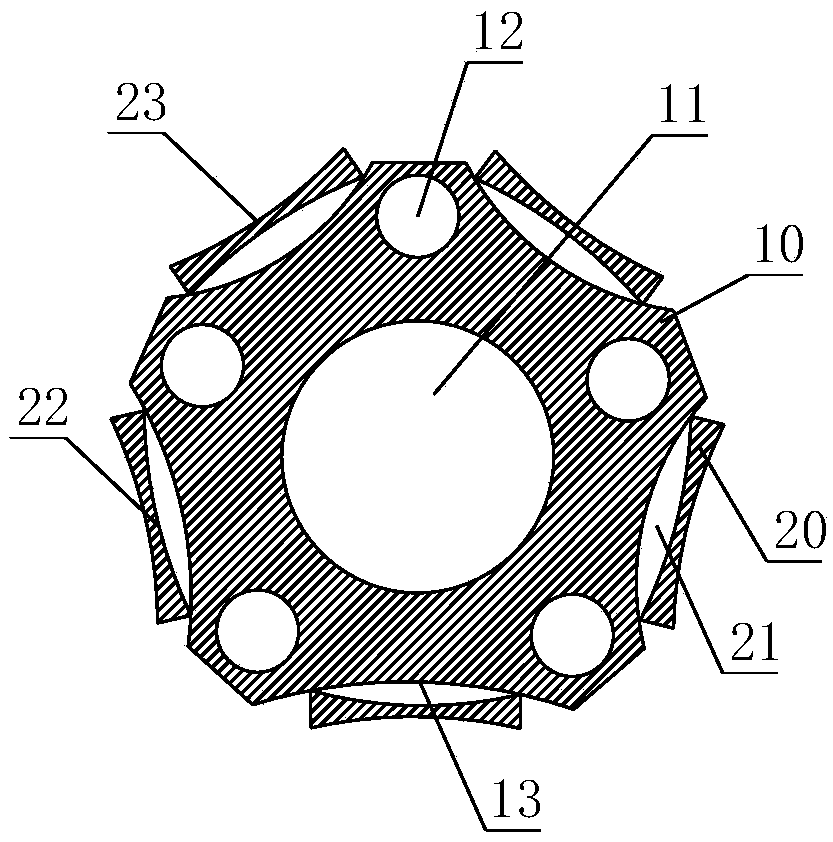

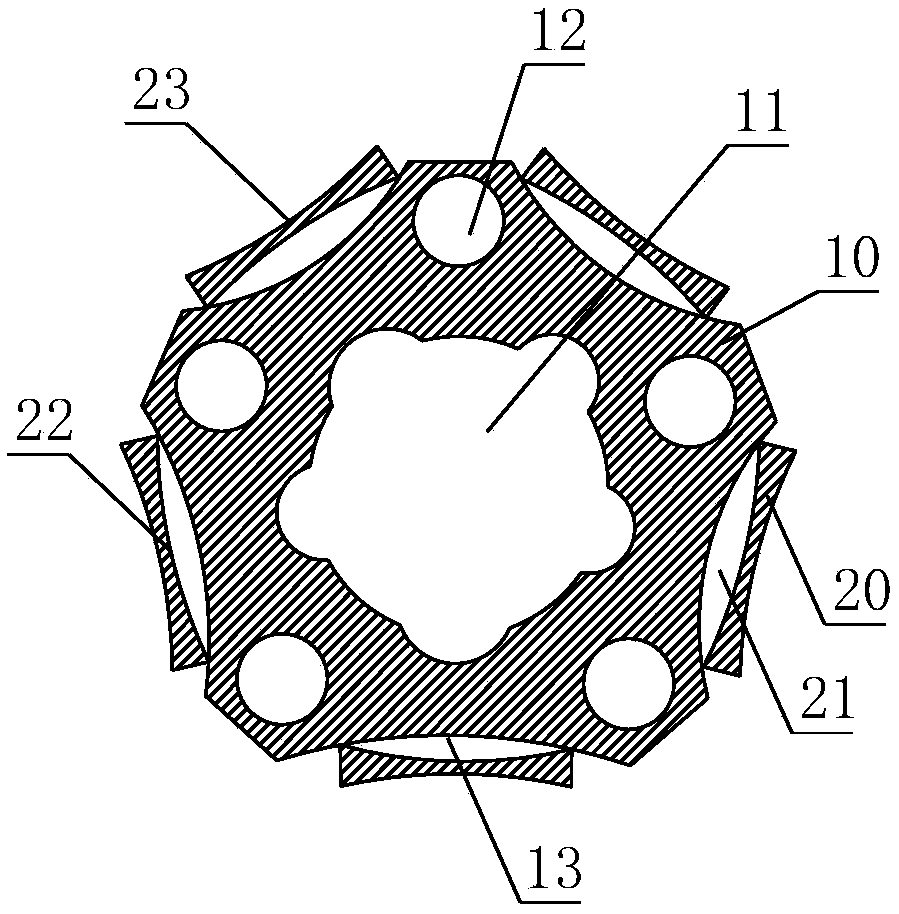

[0030] A better solution is, for example, figure 1 As shown, the polyester monofilament fibers are shaped fibers. The fiber includes a core fiber 10, the core fiber 10 is in the shape of a circular tube, the cavity of the circular tube is a first cavity 11, and at least five first grooves 13 are provided through the outer wall of the core fiber 10 in the axial direction , each first groove 13 is evenly distributed along the peripheral surface of the circular tube. The penetration refers to penetration along the length direction of the core fiber 10 . It should be understood that the cross-section of the core fiber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com