Stringer-type rail structure capable of drainage

A technology of longitudinal beams and tracks, applied in the field of longitudinal beam track structures, can solve problems such as uneven deformation of track structures, endangering driving safety, insufficient rigidity, etc., and achieve the effects of preventing water damage, simple structure, and easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

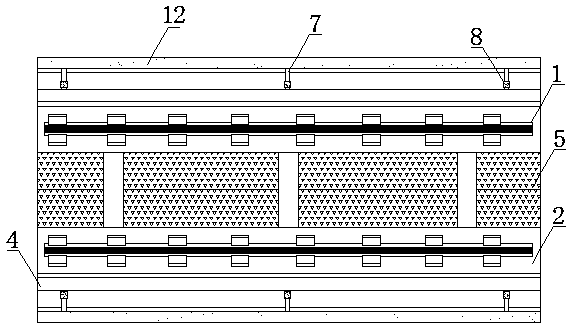

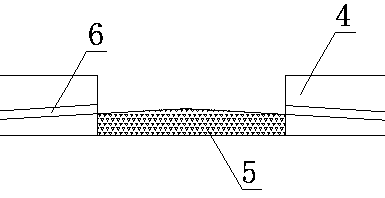

[0025] A drainable longitudinal beam track structure, comprising a steel rail 1, a longitudinal beam sleeper 2 at the lower part of the rail 1, a shock-absorbing pad 3 is arranged between the longitudinal beam sleeper 2 and a lower concrete base 4, and the concrete base 4 Set up a horizontal drainage pipe 6, and set up a herringbone rail fill 5 between the concrete bases 4 on both sides to leave seepage water, and drain the accumulated water around the track to the tunnel side trench 9 on both sides through the horizontal drainage pipe 6 and PVC pipe 7 To go, the horizontal drain pipe 6 and the PVC pipe 7 are connected by a sleeve 8. A PE fence 10 is installed at the entrance of the horizontal drainage pipe 6, and the PE fence 10 can prevent the coal lump scattered during transportation from flowing into the horizontal drainage pipe 6 with water and block the horizontal drainage pipe 6.

Embodiment 2

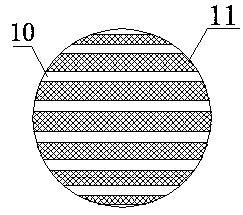

[0027] A drainable longitudinal beam track structure, comprising a steel rail 1, a longitudinal beam sleeper 2 at the lower part of the rail 1, a shock-absorbing pad 3 is arranged between the longitudinal beam sleeper 2 and a lower concrete base 4, and the concrete base 4 Set up a horizontal drainage pipe 6, and set up a herringbone rail fill 5 between the concrete bases 4 on both sides to leave seepage water, and drain the accumulated water around the track to the tunnel side trench 9 on both sides through the horizontal drainage pipe 6 and PVC pipe 7 To go, the horizontal drain pipe 6 and the PVC pipe 7 are connected by a sleeve 8. A PE fence 10 is installed at the entrance of the horizontal drainage pipe 6, and the PE fence 10 can prevent the coal lump scattered during transportation from flowing into the horizontal drainage pipe 6 with water and block the horizontal drainage pipe 6. A long-fiber hot-tie non-woven fabric 11 is arranged inside the PE fence 10, and the long-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com