Concrete conveying pump for mine sump

A technology for concrete delivery pumps and water tanks, which is applied to components, pumps, and drainage of pumping devices for elastic fluids, and can solve problems affecting the progress of water tank cleaning and excavation, shorten the cleaning and excavation cycle, and improve labor efficiency , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

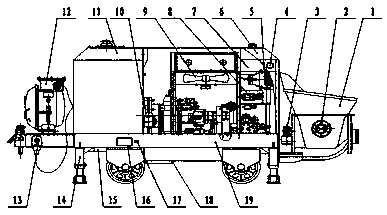

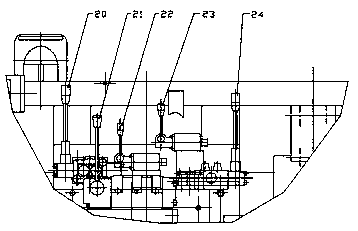

[0019] Such as Figure 1-2 As shown, a concrete delivery pump for a coal mine water tank includes a hopper 1, a motor and a stirring mechanism 2, an S pipe valve and a swing mechanism 3, an outer cover 6, an accelerator tank 7, a hydraulic system 8, a cooling oil fan 9, and a conveying Pump motor 10, fuel tank 11, vacuum magnetic starter 12, support mechanism 14, pumping main cylinder 15, water tank 18, frame 19, a hopper 1 is installed on the right side of the frame 19, and a motor is installed in the hopper 1 and stirring mechanism 2, and S pipe valve and swing mechanism 3 are installed on the left side of hopper 2, outer cover 6 is integrally installed on the top of the frame 19, accelerator box 7 is installed on the right side top of the outer cover 6, and the outer cover 6, a hydraulic system 8 is installed in the middle right side of the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com