Side-blowing type oxygen-enriched molten pool smelting furnace

An oxygen-enriched molten pool smelting, side-blown technology, applied in furnaces, furnace cooling, furnace components, etc., can solve the problems of worker hazards in environmental operation, inability to efficiently control temperature, and affect smelting efficiency. The effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

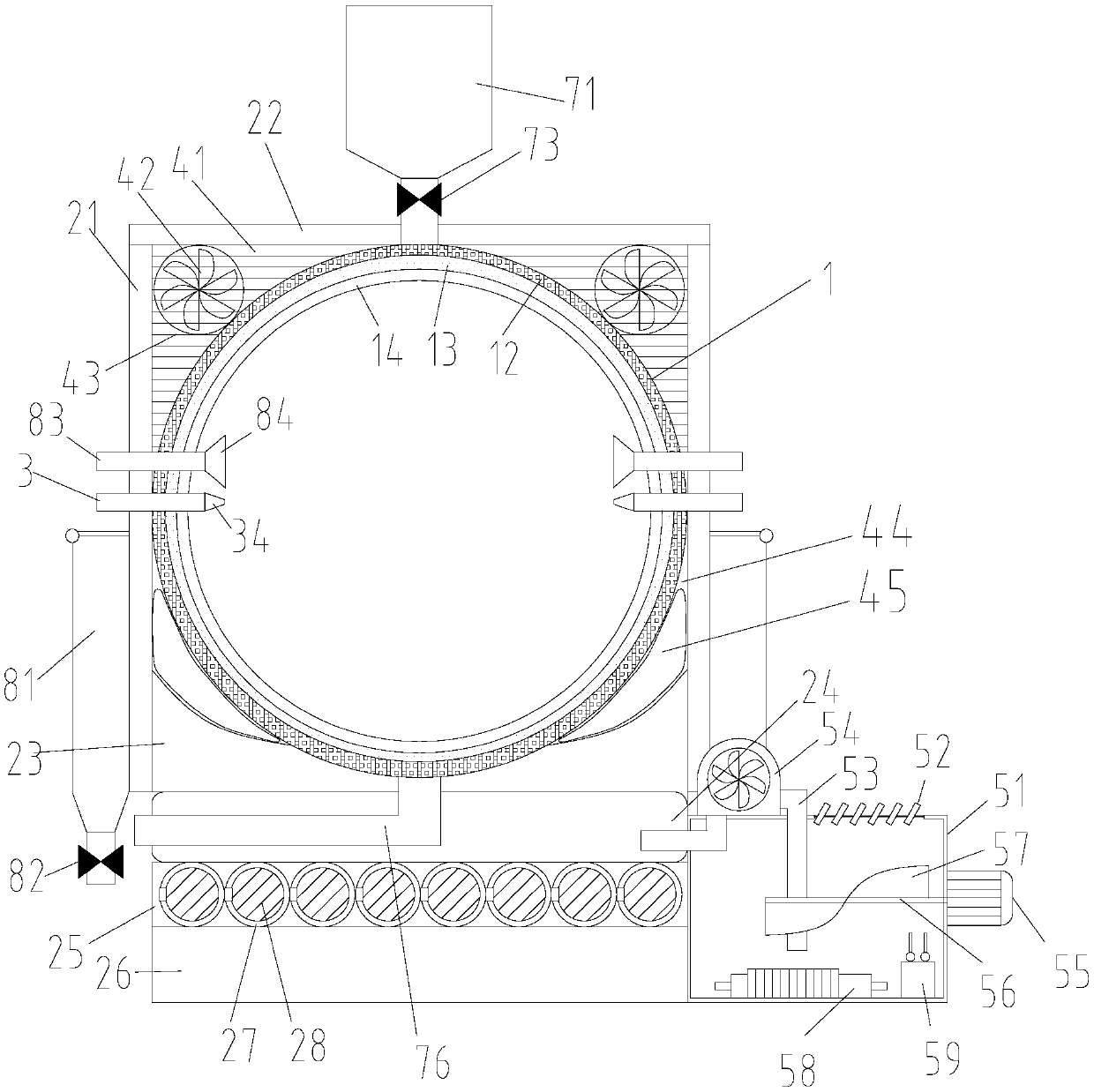

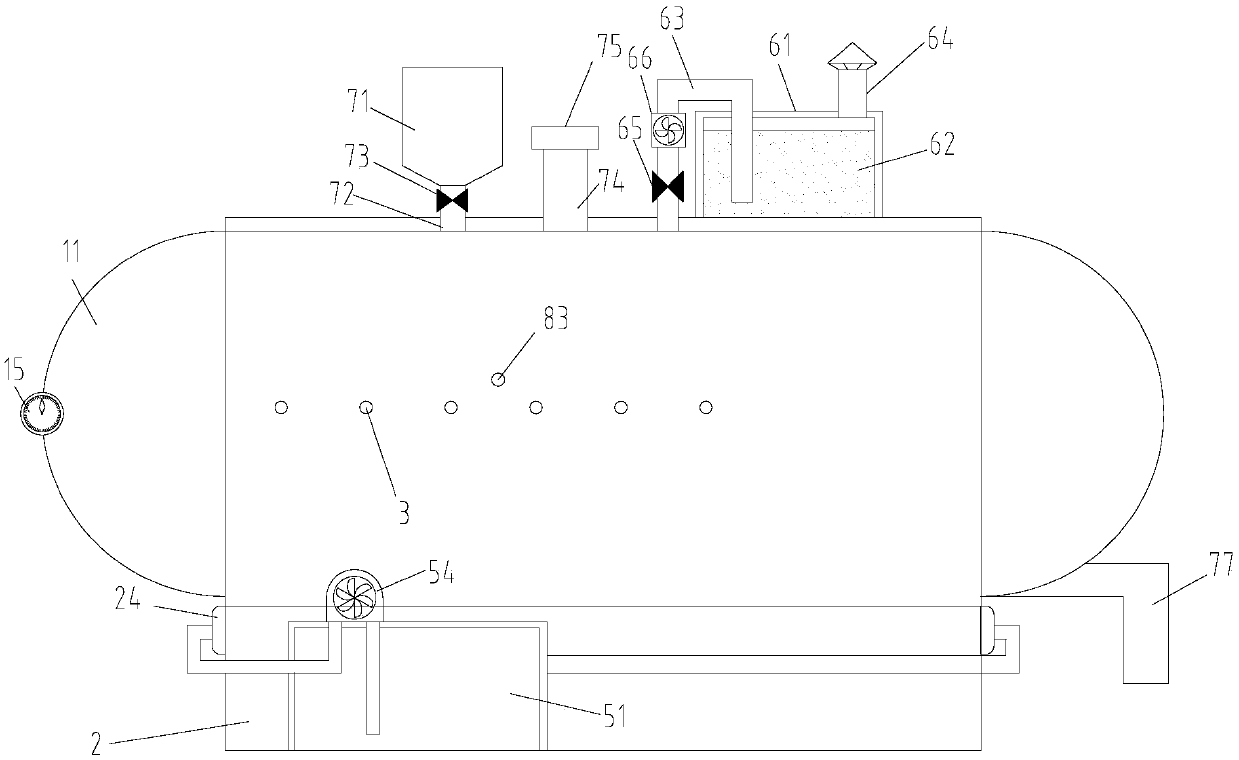

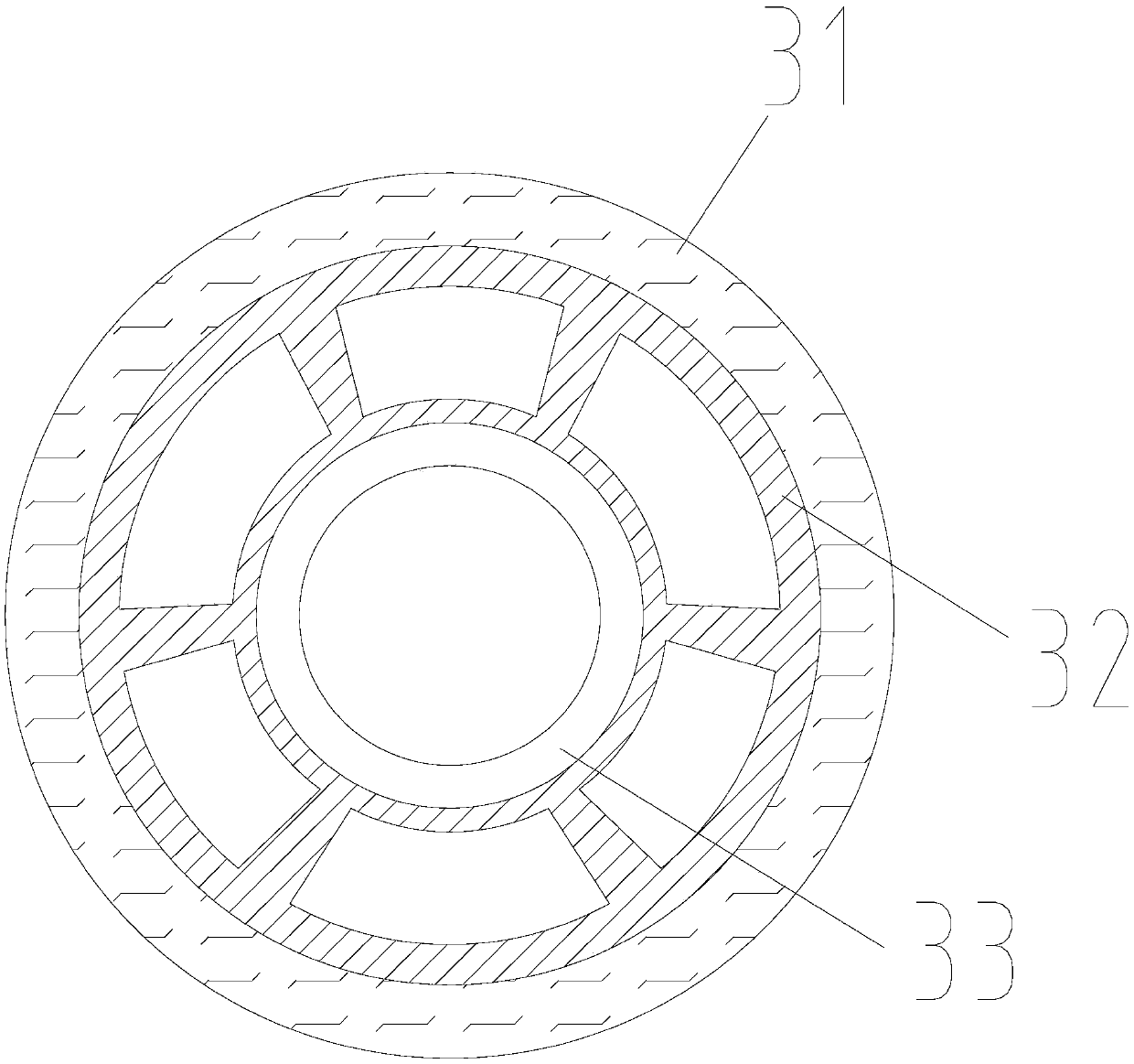

[0023] like figure 1 , figure 2As shown, the embodiment provides a side-blown oxygen-enriched molten pool melting furnace, including a furnace body 1, a bracket, a spray gun 3, a discharge pipe 77, a waste pipe 76, a charging box 71, a treatment box 61, and a water tank 51. The middle part of the furnace body 1 is configured as a cylinder, and the front and rear ends of the furnace body 1 are configured as spherical covers 11 communicating with the middle part. The bracket includes two protective plates 21, a cover plate 22 and a base 2. The base 2 includes a refractory layer 23, a water tank 24, a ventilation pipe layer 25 and a support platform 26 fixed in order from top to bottom, and the ventilation pipe layer 25 is fixed horizontally. There are a plurality of ventilation pipes 27, two protective plates 21 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com