Device for dynamically analyzing and detecting gaseous product

A technology for detecting gas and products, applied in the field of chemical analysis, can solve problems such as inability to obtain good application and slow reaction rate, and achieve the effects of rich dynamic detection methods, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

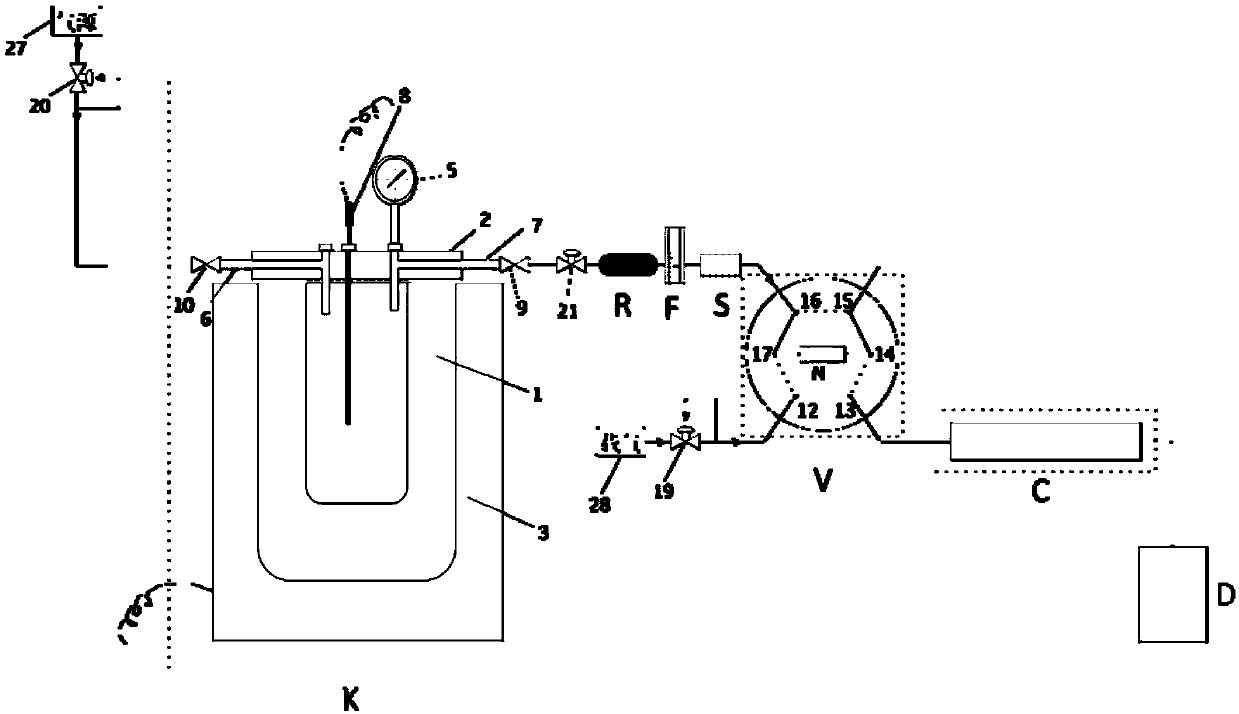

[0024] A device for dynamic analysis and detection of gas-phase products, wherein the high-pressure reactor is a gas-phase reaction type high-pressure reactor, and its structural diagram is as follows figure 1 As shown, it includes autoclave K, gas source or carrier gas source 27, the second carrier gas source 28, automatic sampling valve V, quantitative tube N chromatographic column C and detector D; autoclave K includes still cavity 1, Kettle cover 2 and electric heating furnace 3, are provided with pressure gauge 5, air inlet channel 6, outlet channel 7, thermocouple 8, airway switch valve 9,10 on the kettle cover 2; 1 forms a sealed space, and the electric furnace 3 is arranged on the periphery of the still cavity 1 for 3 heating the material in the still cavity 1; the thermocouple 8 extends into the still cavity 1 through the kettle cover 2 to measure the temperature in the still cavity 1; One end of the channel 6 and its air channel switching valve 10 is connected to the...

Embodiment 2

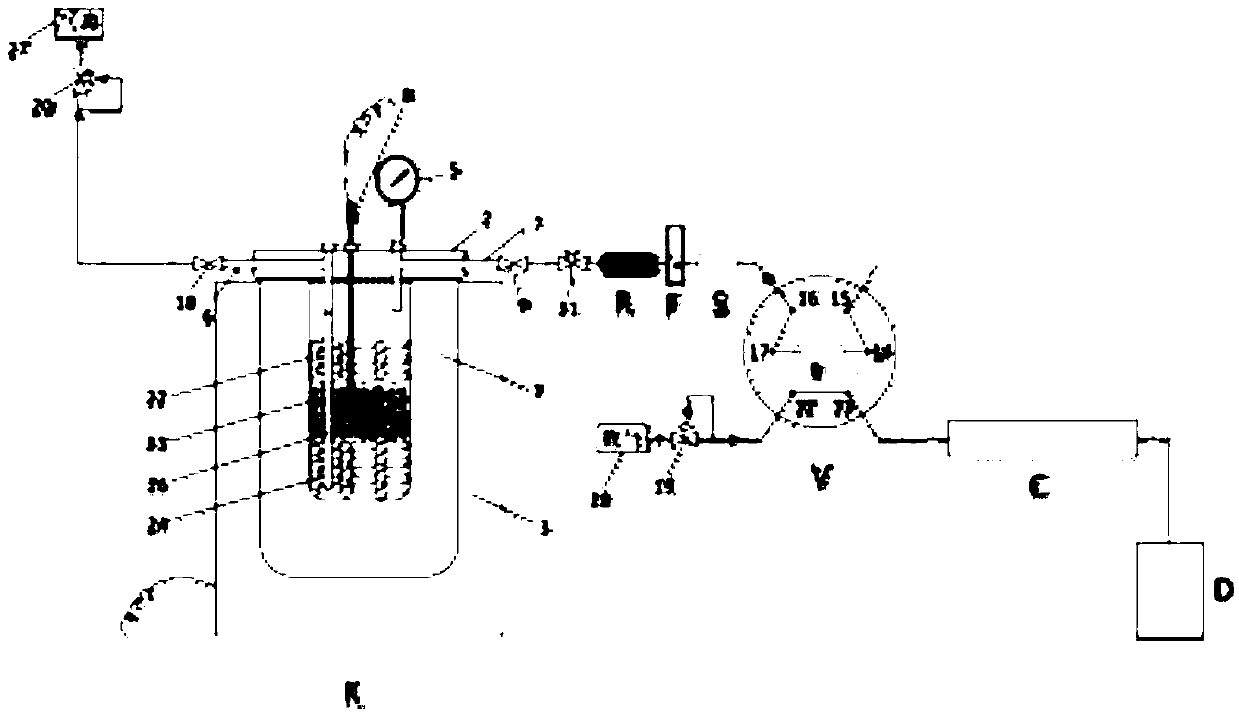

[0027] A device for dynamic analysis and detection of gas-phase products, wherein the high-pressure reactor is a gas-phase reaction type high-pressure reactor, and its structural diagram is as follows figure 2Shown, except that with embodiment 1 identical setting and parts, gas source or carrier gas source 27 is used as the gas source that is catalyzed, i.e. gas source, and in the still cavity 1 of autoclave K from top to bottom Fill the first absorbent cotton layer 22, the catalyst layer 23 and the second absorbent cotton layer 24 in sequence; connected, and the other end stretches into the bottom of the still cavity 1. In a preferred scheme, the thicknesses of the first absorbent cotton layer 22, the catalyst layer 23 and the second absorbent cotton layer 24 each account for 1 / 4 of the height of the still cavity 1, and the upper layer of the abdominal cavity (1) remains 1 / 4 height space.

[0028] The working process of the device in this embodiment is: the catalyzed gas en...

Embodiment 3

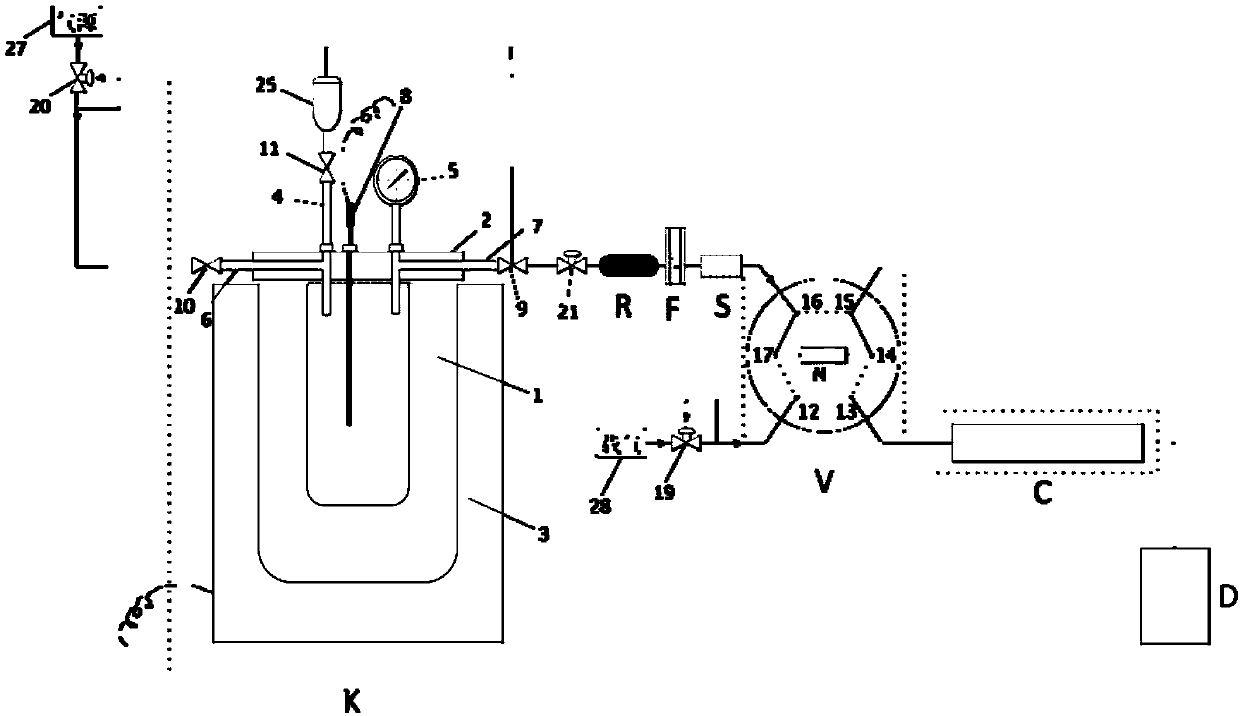

[0033] A device for dynamic analysis and detection of reaction gas phase products, wherein the high-pressure reactor is a non-gas phase reaction high-pressure reactor, and its structural diagram is as follows image 3 As shown, in addition to the same settings and parts as in Example 1, the gas source or carrier gas source 27 is used as the first carrier gas source, and the lid of the non-gas-phase reaction type high-pressure reactor is also provided with a liquid sampling port 4 , the liquid inlet is connected to the inside and outside of the still chamber 1, so as to fill the liquid reactant into the kettle chamber, the rear end of the liquid inlet 4 is provided with a liquid inlet switch valve 11, and the liquid inlet switch valve 11 is used to control the reaction The speed and amount of liquid reactants injected into the still cavity 1. In the preferred scheme, a liquid sampler 25 is connected to the front end of the liquid sample inlet, and it is a constant pressure liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com