Magnetic core assembly for high-frequency transformer and high-frequency transformer

A high-frequency transformer and magnetic core technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc., can solve high-frequency eddy current loss, transformer working flux and inductance influence, magnetic circuit Problems such as large dispersion of parameters can achieve the effects of reducing operating temperature rise, eliminating eddy current loss, and eliminating leakage magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

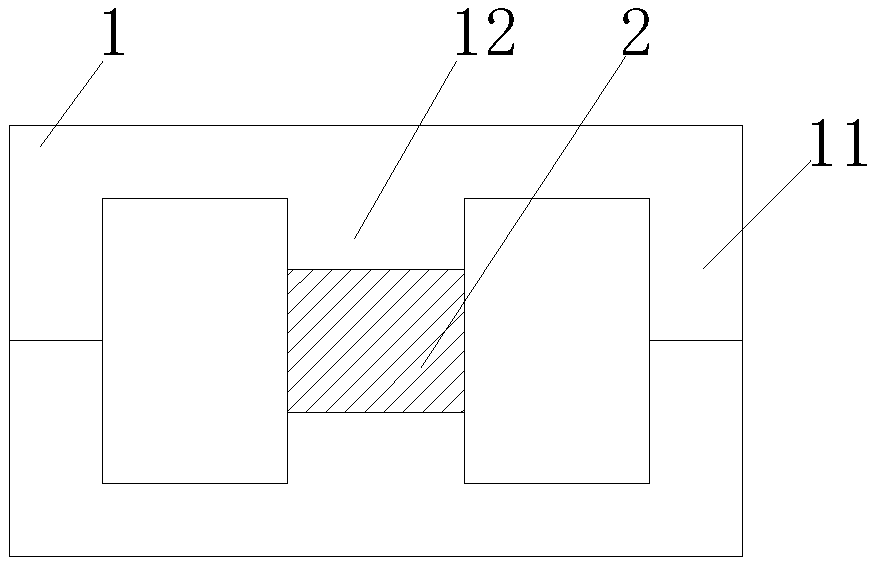

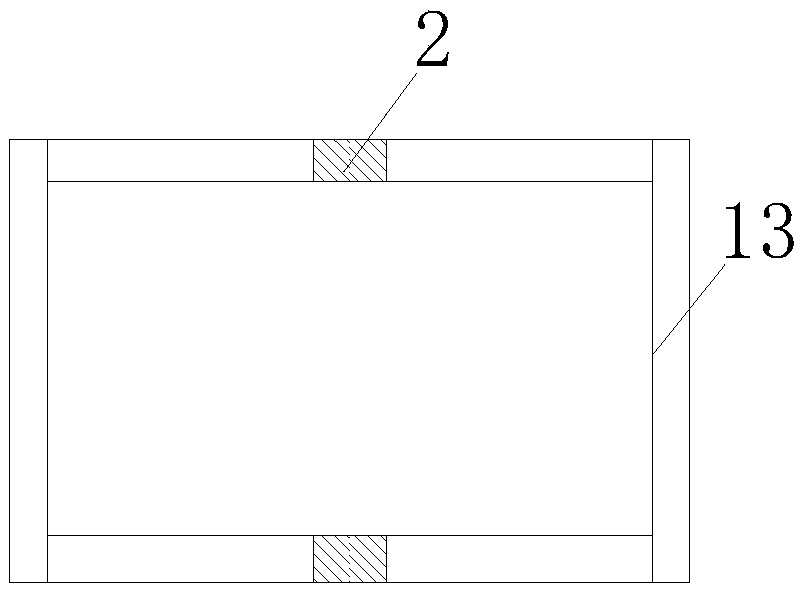

[0022] to combine figure 1 , a high-frequency transformer magnetic core assembly proposed by the present invention, the magnetic core assembly includes two magnetic core bodies 1 and an auxiliary magnetic core body 2, the two magnetic core bodies 1 are connected to the auxiliary magnetic core body 2, and Cooperating to form a closed magnetic circuit without an air gap, the magnetic permeability of the magnetic core body 1 is greater than that of the auxiliary magnetic core body 2 .

[0023] The magnetic core body 1 can be made of a material with a relatively high magnetic permeability, such as manganese zinc ferrite, and the magnetic core body 1 can be made of a material with a small magnetic permeability, such as sendust and hydroxy iron powder.

[0024] The magnetic core body 1 is the main body material of the magnetic core assembly, which accounts for most of the volume of the magnetic core. Auxiliary sub-cores are auxiliary materials that occupy a small portion of the vol...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that this embodiment discloses a high-frequency transformer, including a bobbin, a winding coil, and a high-frequency transformer core assembly. The high-frequency transformer core assembly in this embodiment is the same as that in the embodiment The core components of the high-frequency transformer in 1 are exactly the same, so they will not be repeated here to save space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com