Packaging structure of crimping type dual-core GCT

A packaging structure, crimping technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problem of uneven transmission of current drive signals, double gate control signals cannot be drawn out of the shell and drive circuit boards, and current is concentrated. and other problems, to meet the requirements of heat dissipation characteristics, small size, and ensure the effect of transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

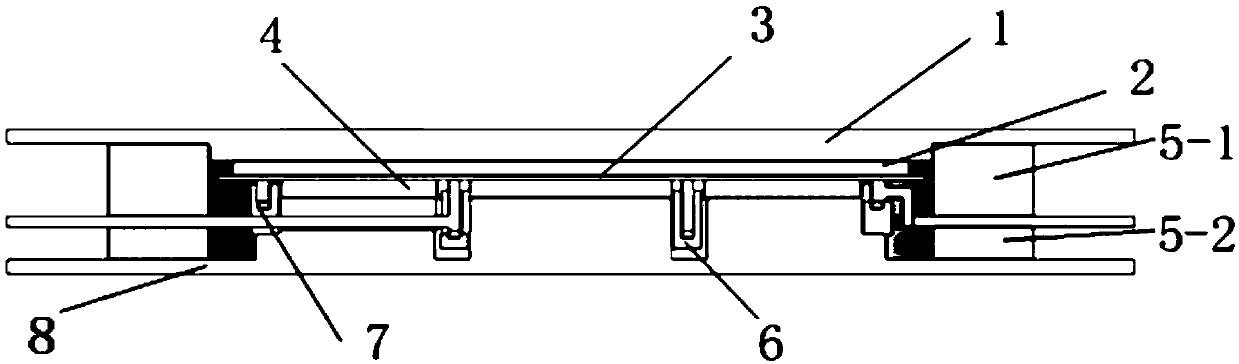

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

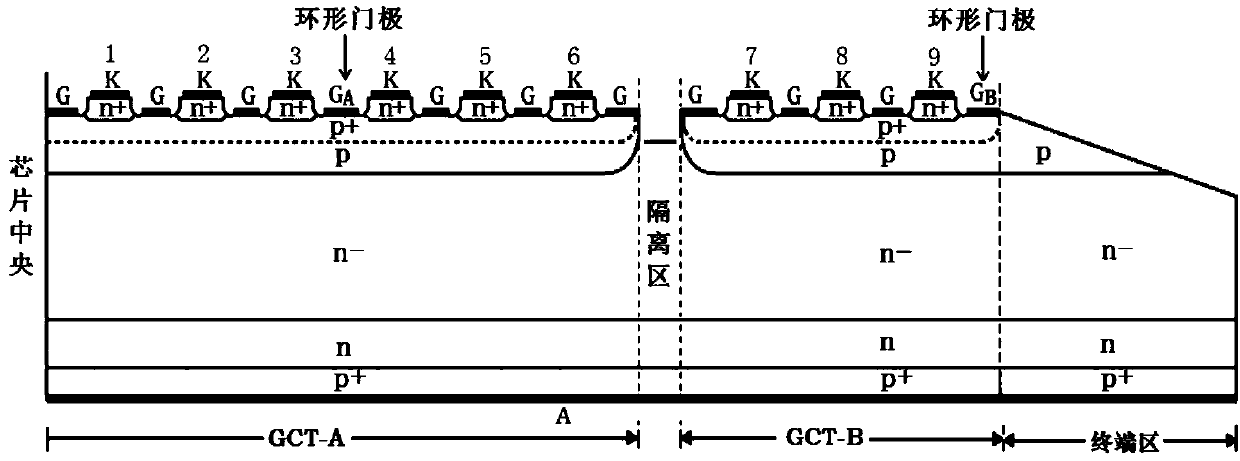

[0032] refer to figure 1 , the cross-section (along the radial direction) structure of the dual-core GCT chip 3 in the packaging structure of the present invention is that the embodiment cathode strip is provided with 9 rings in total, and GCT-A is positioned at the center of the chip, and its inner gate G A It is located between the 3 rings and 4 rings of the cathode strip; GCT-B is located on the periphery of the chip, and its outer gate G B It is located at the junction of the chip cathode strip 9 ring (active area) and the terminal area; an isolation area is set between GCT-A and GCT-B, and the isolation area adopts a pnp structure to realize isolation.

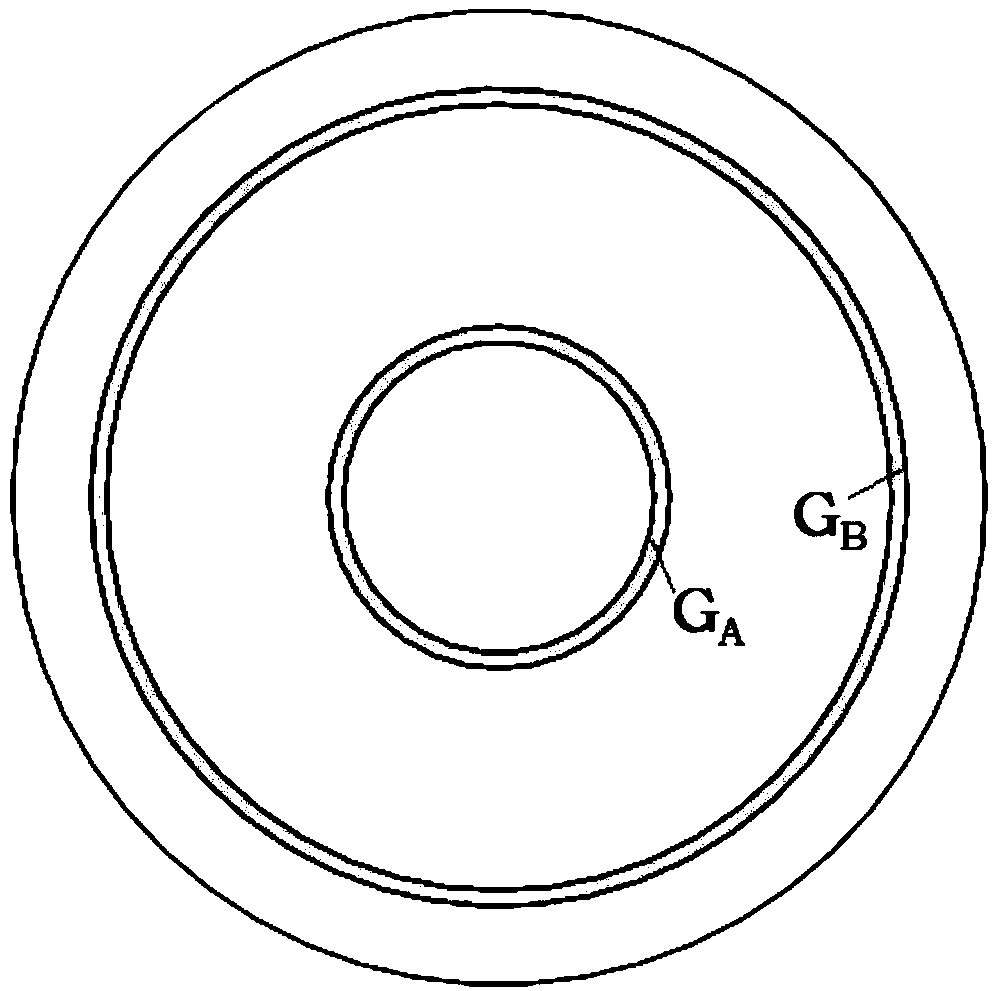

[0033] refer to figure 2 , is the top view structure of the gate in the packaging structure of the present invention, the inner gate G A and outer gate G B For the concentric settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com