Lithium seawater battery diaphragm, fixed sealing material and sealing method thereof

A seawater battery and sealing material technology, which is applied to sealing materials, immersed batteries, battery pack components, etc., can solve problems such as difficulty in achieving good sealing, battery failure, and water ingress of battery negative electrodes, and achieve good fixed sealing characteristics, good Fixing effect, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

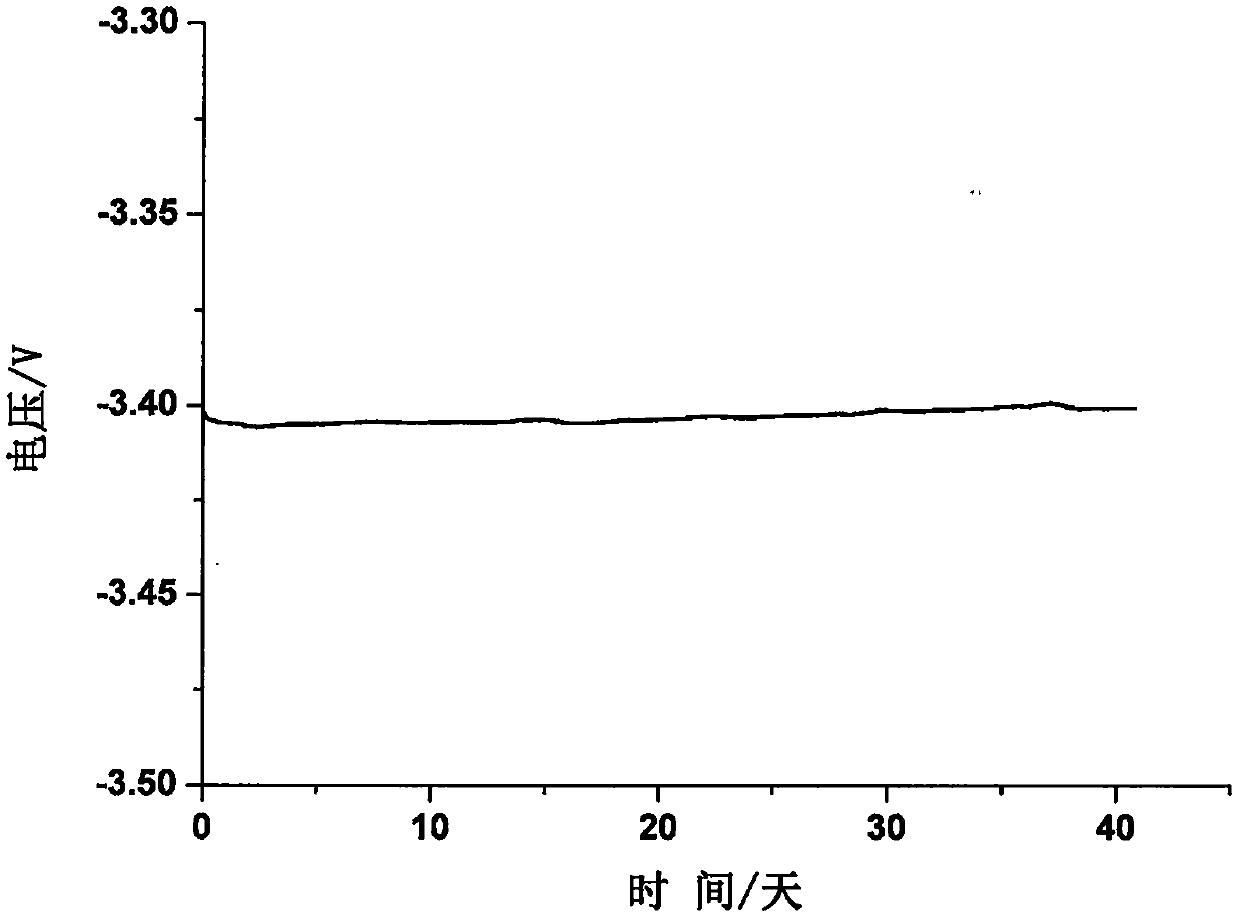

Embodiment 1

[0032] A lithium seawater battery window, the window is a solid electrolyte window, which is Li 1.3 Al 0.3 Ge 1.7 (PO 4 ) 3 , with a size of 2.1 cm × 2.1 cm × 300 μm.

[0033] A lithium seawater battery window plate fixing sealing material, including resin, diluent, wetting agent and polyethylene / polypropylene composite ear glue, the resin is E-51 type bisphenol A epoxy resin and modified amines Moist underwater epoxy (MA) curing agent. The diluent is N-methylpyrrolidone. The wetting agent is ethanol. The polyethylene / polypropylene composite ear glue is composed of polyethylene ear glue and polypropylene ear glue, the polypropylene ear glue is used as the intermediate structural support layer, and the polyethylene ear glue is used as the bonding layer in the middle The two sides of the structural support layer form a three-layer sandwich structure, and the density of polyethylene ear glue is 0.976g / cm 3 , the density of high-density polypropylene ear glue is 0.92g / cm 3 ...

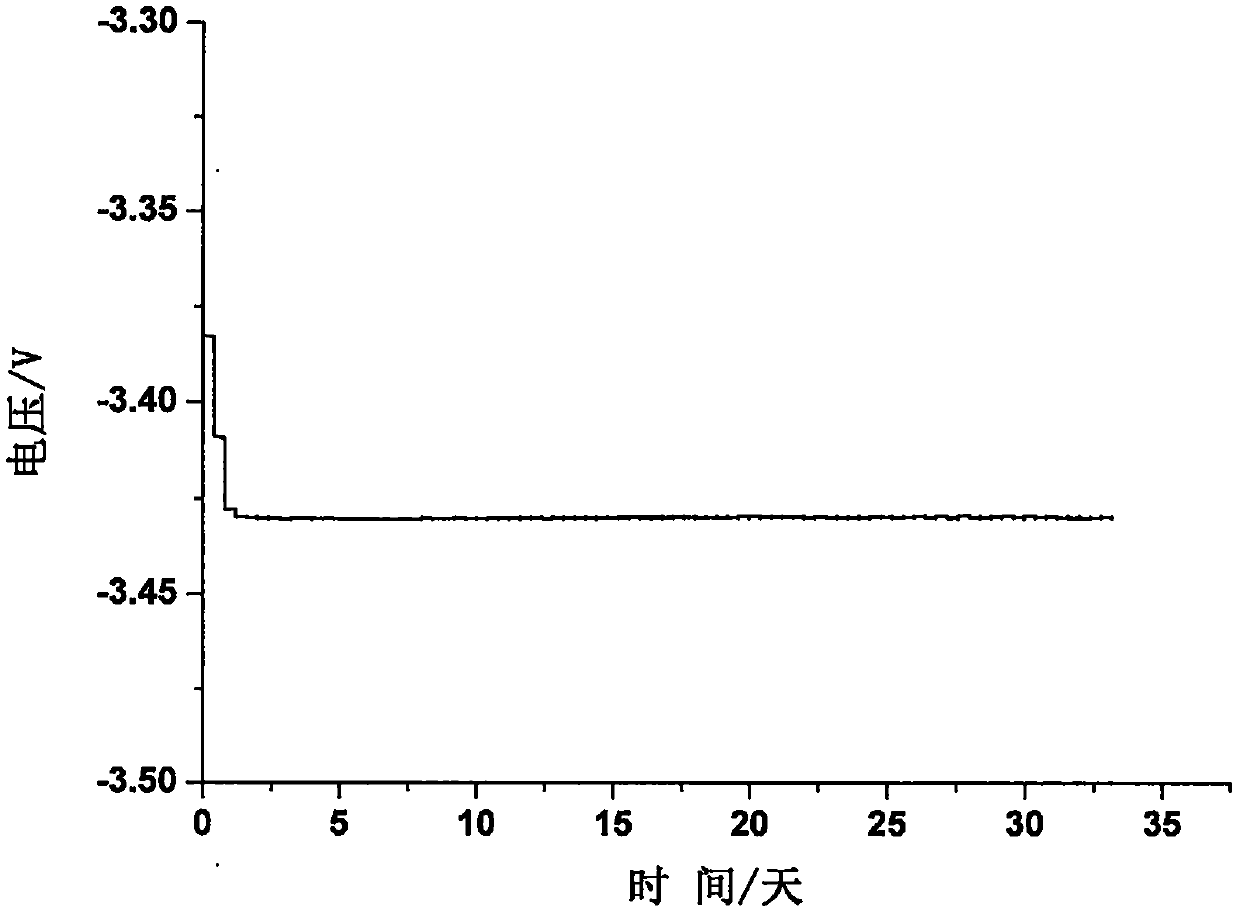

Embodiment 2

[0043] A lithium seawater battery window, the window is a solid electrolyte window, which is Li 1.3 Al 0.3 Ge 1.7 (PO 4 ) 3 , with a size of 2.1 cm × 2.1 cm × 300 μm.

[0044] A lithium seawater battery window fixing sealing material, including resin, diluent, wetting agent and polyethylene / polypropylene composite tab glue, the resin is E-44 type bisphenol A epoxy resin and curing agent T31, The mass ratio of the two is 5:1; the diluent is acetone; the wetting agent is ethylene glycol; the polyethylene / polypropylene composite ear glue is the same as in Example 1.

[0045] A method for fixing and sealing a lithium seawater battery window, comprising the following steps:

[0046] (1) Weigh 0.5g E-44 type bisphenol A epoxy resin and 0.1g curing agent T31 (10 parts by mass) respectively, add 4.05g (67.5 parts by mass) acetone and 1.35g ethyl alcohol after mixing evenly Diol (22.5 parts by mass) was stirred to obtain a clear solution for use.

[0047] (2) Scrape the clarifie...

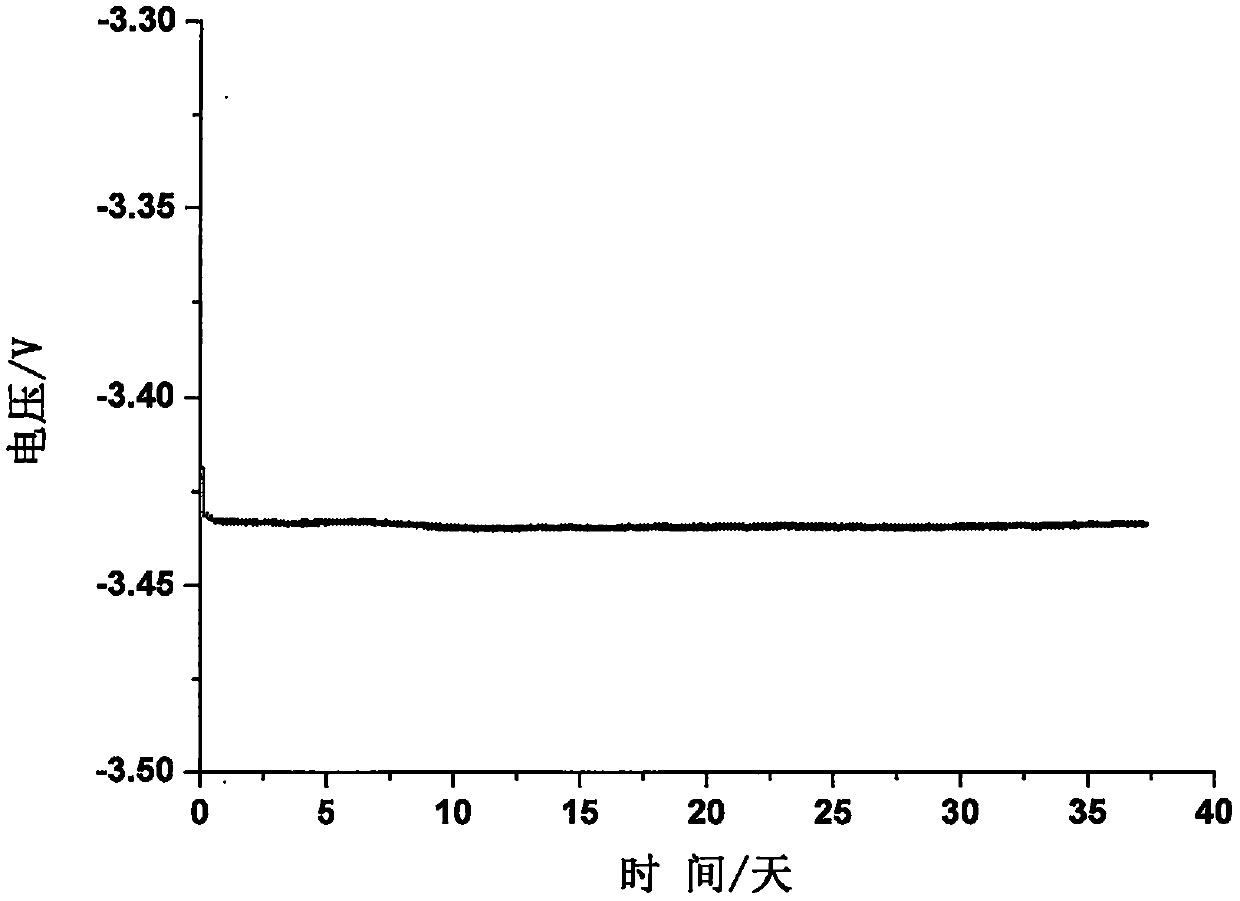

Embodiment 3

[0052] A lithium seawater battery window, the window is a solid electrolyte window, which is Li 1.3 Al 0.3 Ge 1.7 (PO 4 ) 3 , with a size of 2.1 cm × 2.1 cm × 300 μm.

[0053] A lithium seawater battery window plate fixing sealing material, including resin, diluent, wetting agent and polyethylene / polypropylene composite ear glue, the resin is E-41 type bisphenol A epoxy resin and curing agent diethylene oxide Ethyltriamine, the mass ratio of the two is 100:9; the diluent is toluene; the wetting agent is methanol; the polyethylene / polypropylene composite ear glue is the same as in Example 1.

[0054] A method for fixing and sealing a lithium seawater battery window, comprising the following steps:

[0055] (1) Weigh 0.5g E-41 type bisphenol A epoxy resin and 0.045g curing agent diethylenetriamine (10 parts by mass) respectively, add 4.36g toluene (80 parts by mass) after mixing evenly ) and 0.545g methanol were stirred (10 parts by mass) to obtain a clear solution for lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com