Electric-arc additive manufacturing repair method adopting auxiliary forming plate structure

A technology of additive manufacturing and repair methods, applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of poor molding, low cost, low molding efficiency, etc., achieve important engineering application value, and have a wide range of applicable materials , Improve the effect of repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

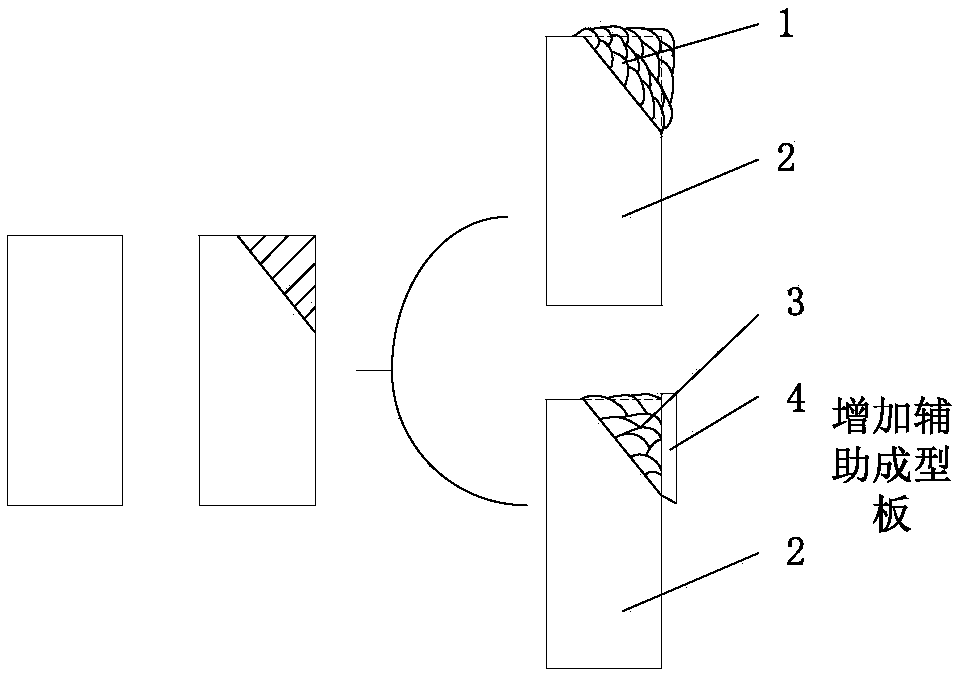

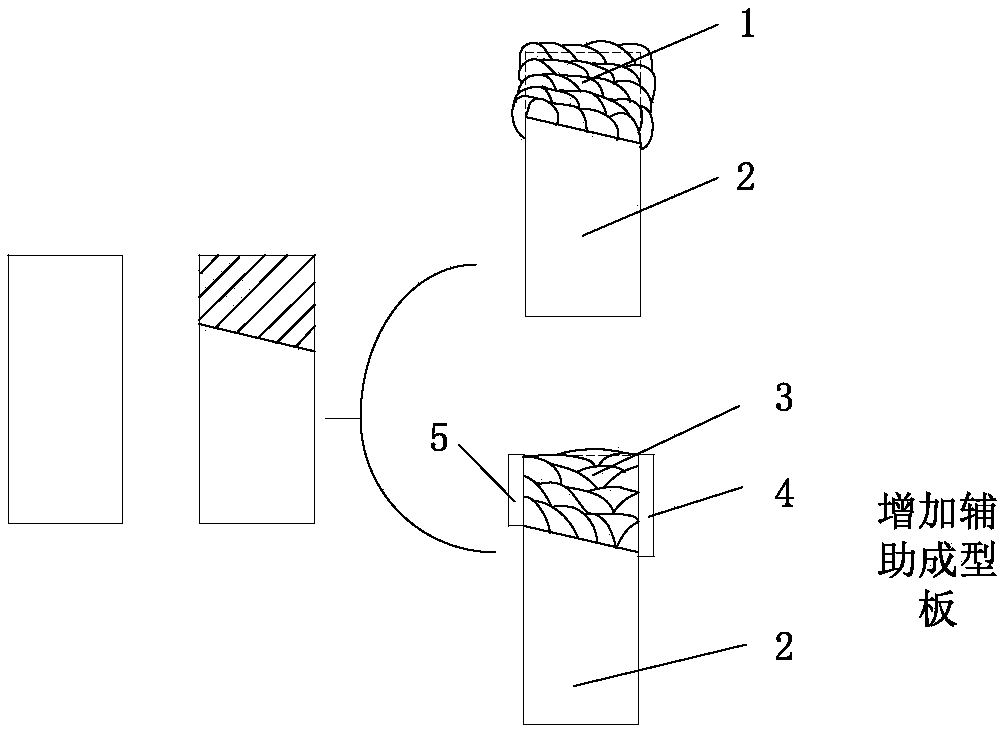

[0010] Specific implementation mode one: the following combination figure 1 , figure 2 To describe this embodiment, figure 1 Shown is a schematic diagram of the arc additive manufacturing repair auxiliary plate structure and method for the defect in the upper right part of the cuboid part according to an embodiment of the present invention, wherein 1 is the repair filling metal without using the auxiliary forming plate, 2 is the metal part to be repaired, and 3 is Restoration filler metal using auxiliary forming plates, 4 for auxiliary forming plates. Taking a simple part as an example, cracks, breakages, and defects occurred in the upper right corner of the cuboid part. The defect area in the upper right corner was mechanically removed to reveal the metallic luster. The additive manufacturing repair of the auxiliary forming board was not used to avoid the flow of liquid metal. , it is necessary to tilt the workpiece to be repaired to ensure that the position of the molten ...

specific Embodiment approach 2

[0012] Specific Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the applicable materials for the base metal to be repaired include: steel, aluminum alloy, copper alloy or magnesium alloy and other large-volume defects and regular-shaped metals. Components.

specific Embodiment approach 3

[0013] Specific Embodiment 3: This embodiment is a further limitation of Embodiment 1. In this embodiment, according to the service performance requirements of the final repaired parts, the repair material can be selected using the principle of high-strength matching to improve the material strength of the repaired part. It can also be used The principle of equal-strength matching or low-strength matching is used to select repair filling materials to improve the plasticity and toughness of the repaired parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com