Wood cutting device for architectural decoration

A cutting device and architectural decoration technology, applied in wood processing equipment, forming/shaping machines, special forming/shaping machines, etc., can solve the problems of user injury, wood deviation, wood scrapping, etc., to avoid damage, avoid The effect of scrapping and cutting smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

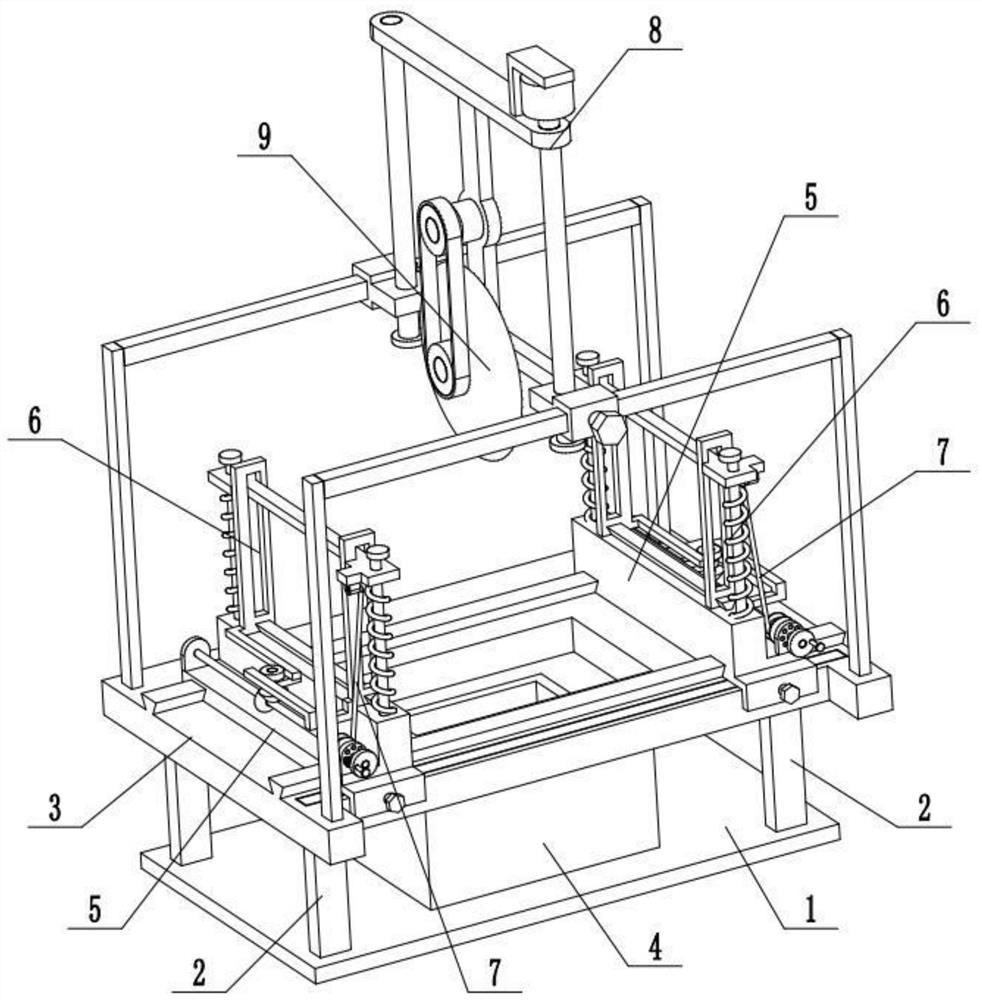

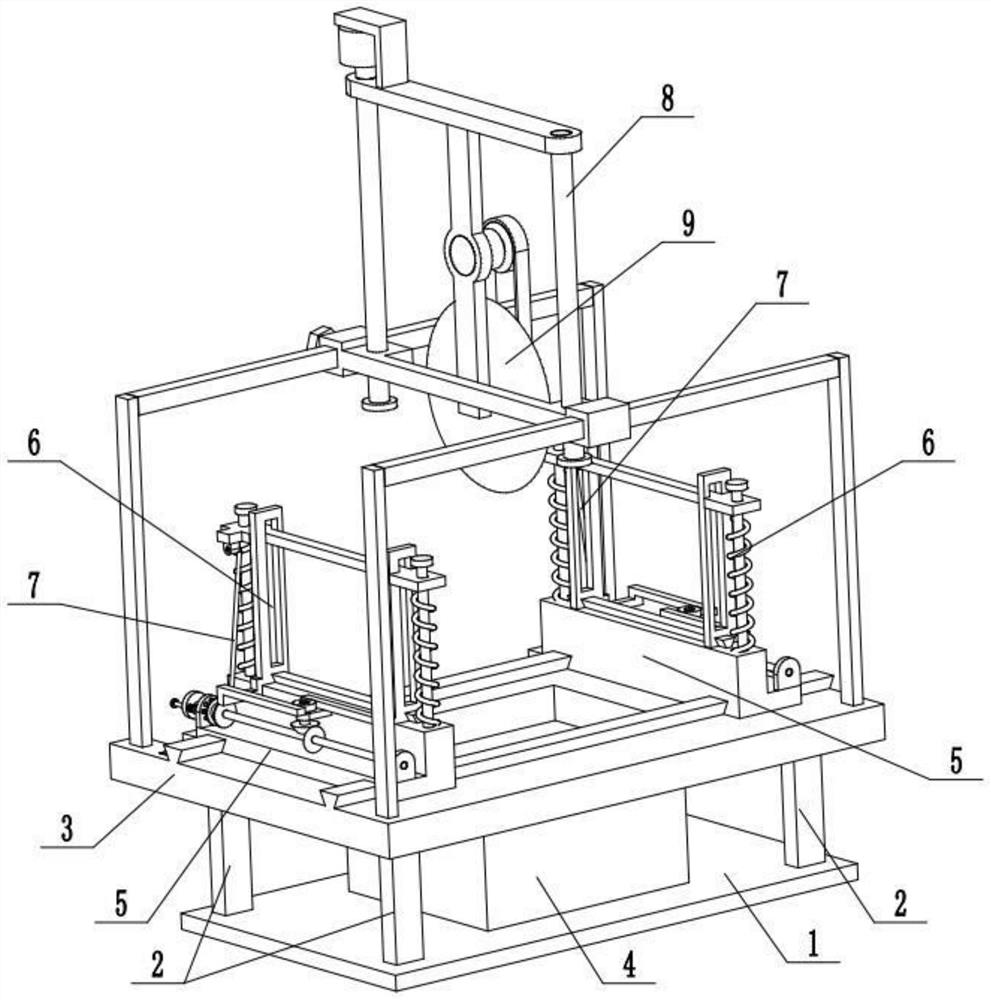

[0025] Combine below Figure 1-7 Description of this embodiment, a wood cutting device for architectural decoration, including a base 1, supporting legs 2, a horizontal working plate 3, a sawdust recovery box 4, a fixing slide 5, a wood fixing assembly 6, a nylon rope 7, a cutting slide Seat 8 and cutting device 9, the four corners of the top surface of the base 1 are respectively fixedly connected to a support leg 2, the horizontal working board 3 is fixedly connected to the four support legs 2, and the sawdust recovery box 4 is placed in the center of the base 1 position, the sawdust recovery box 4 is located below the horizontal working plate 3, two fixing slides 5 are provided, and the two fixing slides 5 are symmetrically slidably connected to the lower end of the horizontal working plate 3, and the two fixing slides 5 are Connect a wood fixing assembly 6 respectively, the front ends of the upper ends of the two wood fixing assemblies 6 are respectively fixedly connected ...

specific Embodiment approach 2

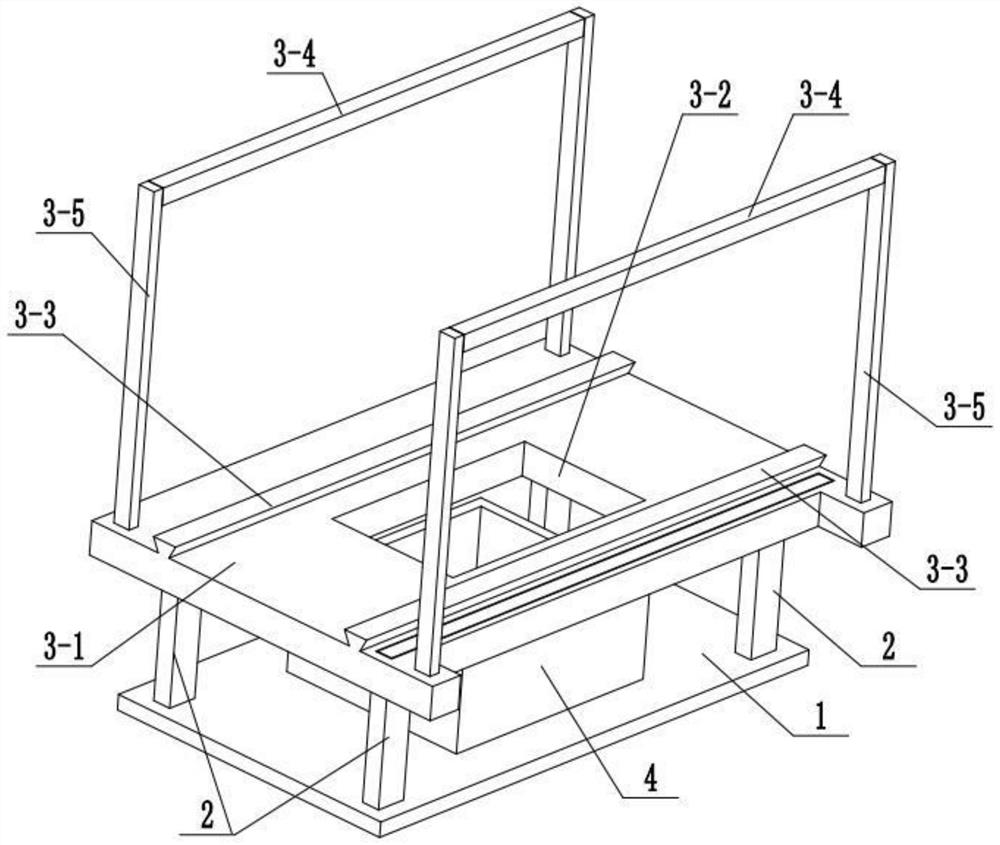

[0027] Combine below Figure 1-7To illustrate this embodiment, the horizontal working board 3 includes a working board body 3-1, a chip removal channel 3-2, a trapezoidal slide rail 3-3, a beam 3-4 and a vertical bar 3-5; the working board body 3 -1 is fixedly connected to the four support legs 2, the center of the working board body 3-1 is provided with a chip removal channel 3-2, the sawdust recovery box 4 is located below the chip removal channel 3-2, and two trapezoidal slide rails 3 -3 is symmetrically fixedly connected to the two ends of the top surface of the working board body 3-1; there are two crossbeams 3-4, and the two ends of the two crossbeams 3-4 are respectively fixedly connected to a vertical bar 3-5; The crossbeam 3-4 is fixedly connected to the outer ends of the front and rear ends of the working plate body 3-1 through the vertical rod 3-5 respectively. The front end of the working board body 3-1 is provided with a scale, which is convenient for measuring t...

specific Embodiment approach 3

[0029] Combine below Figure 1-7 To illustrate the present embodiment, the fixed element sliding seat 5 includes a sliding base 5-1, a screw fixing seat 5-2, a fastening screw 5-3, a support seat 5-4, a trapezoidal sliding bar 5-5, and a rear seat plate 5-6, front seat plate 5-7, rotating shaft 5-8, driving bevel gear 5-9, rope winding wheel 5-10, jack 5-11 and clip 5-12; sliding base 5-1 is slidably connected on On the two trapezoidal slide rails 3-3, the front end of the sliding base 5-1 is fixedly connected to the horizontal plate of the screw mounting base 5-2, and the vertical plate of the screw mounting base 5-2 is threaded to fasten the screw 5-3. The fixed screw 5-3 is pushed against the front end surface of the working plate body 3-1; the inner end of the sliding base 5-1 is fixedly connected to the support seat 5-4, and the middle end of the top surface of the support seat 5-4 is fixedly connected to the trapezoidal slide Rod 5-5; the front seat plate 5-7 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com