Biochar flocculating agent, and preparation method and application thereof

A flocculant and biochar technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve problems such as slow heavy metal speed and slow water body separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of biochar flocculant, comprising the following steps:

[0025] Vacuum impregnation of biomass material in CaCl 2 solution and Na 2 CO 3 In the solution, after drying, the biochar flocculant is prepared under the condition of high temperature and oxygen isolation. The biomass material is one or more of crop straw, pokeweed straw, bamboo fiber, and wood chips, among which pokeweed straw is used as raw material. Biochar flocculants have higher efficiency in removing heavy metals.

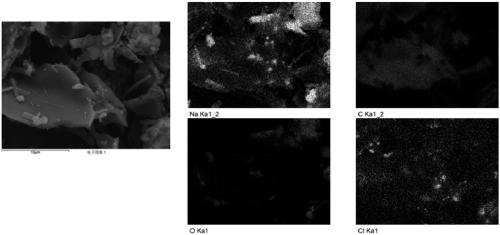

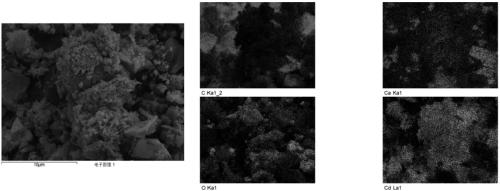

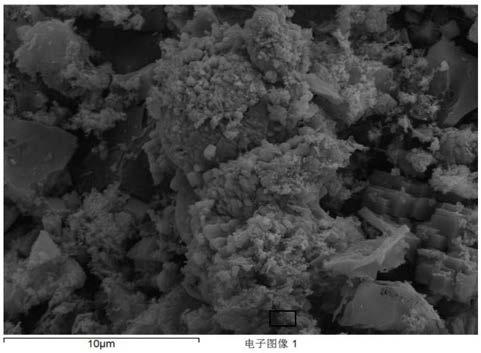

[0026] The main components of biomass such as crop straw, pokeweed straw, bamboo fiber and sawdust used in the invention are cellulose and lignin, and the cellulose and lignin are carbonized under high temperature and oxygen barrier conditions to prepare biochar. Vacuum impregnation of biomass material in CaCl 2 In solution, Ca 2+ Loaded on the surface of biomass, while diffusing into the interior of the biomass material. During the high temperature oxygen barrier pre...

Embodiment 1

[0037] (1) Pokeweed straw, impregnated in CaCl under vacuum 2 solution, CaCl 2 The solution concentration is 0.5mol / L, and the vacuum impregnation time is 12h;

[0038] (2) Vacuum impregnation of CaCl 2 The pokeweed straw after solution was impregnated in Na 2 CO 3 In solution, Na 2 CO 3 The solution concentration is 1mol / L, and the vacuum impregnation time is 12h;

[0039] (3) The dried pokeweed straw was prepared into a biochar flocculant at 400°C under the condition of oxygen isolation;

[0040] (4) 100mg / L biochar flocculant flocculation to remove 100mg / L Cd in water 2+ ;

[0041] (5) After 5min, Cd 2+ The removal rate was 100%.

Embodiment 2

[0043] (1) Corn stalks, impregnated in CaCl under vacuum 2 solution, CaCl 2 The solution concentration is 1mol / L, and the vacuum impregnation time is 24h;

[0044] (2) Vacuum impregnation of CaCl 2 The corn stalks after the solution were impregnated in Na 2 CO 3 In solution, Na 2 CO 3 The solution concentration is 2mol / L, and the vacuum impregnation time is 24h;

[0045] (3) The dried corn stalks were prepared into a biochar flocculant at 500°C under the condition of oxygen isolation;

[0046] (4) 300mg / L biochar flocculant flocculation to remove 100mg / L Cd in water 2+ , 100mg / L Cu 2+ , 200mg / LPb 2+ ;

[0047] (5) After 10min, Cd 2+ 100% removal rate, Pb 2+ 100% removal rate, Cu 2+ The removal rate was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com