Titanium aluminum boron shape memory alloy material, alloy, and production method and application of alloy

A technology of memory alloy and production method, which is applied in the field of memory alloy to achieve the effect of promoting transformation efficiency, reducing manufacturing cost and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the present invention better, content of the present invention is further set forth below in conjunction with specific embodiment, but content of the present invention is not limited only to following embodiment.

[0023] The invention provides a titanium-aluminum-boron shape memory alloy material, the composition of which is Ti: 43-46%, Al: 22-26%, B: 28-35%, and the rest are a small amount of unavoidable impurities.

[0024] The present invention also provides a production method of a titanium-aluminum-boron shape memory alloy, comprising the following steps:

[0025] 1) Mixing the titanium-aluminum-boron shape memory alloy material, the composition of the titanium-aluminum-boron shape memory alloy material is Ti: 43-46%, Al: 22-26%, B: 28-35%, and the rest A small amount of unavoidable impurities;

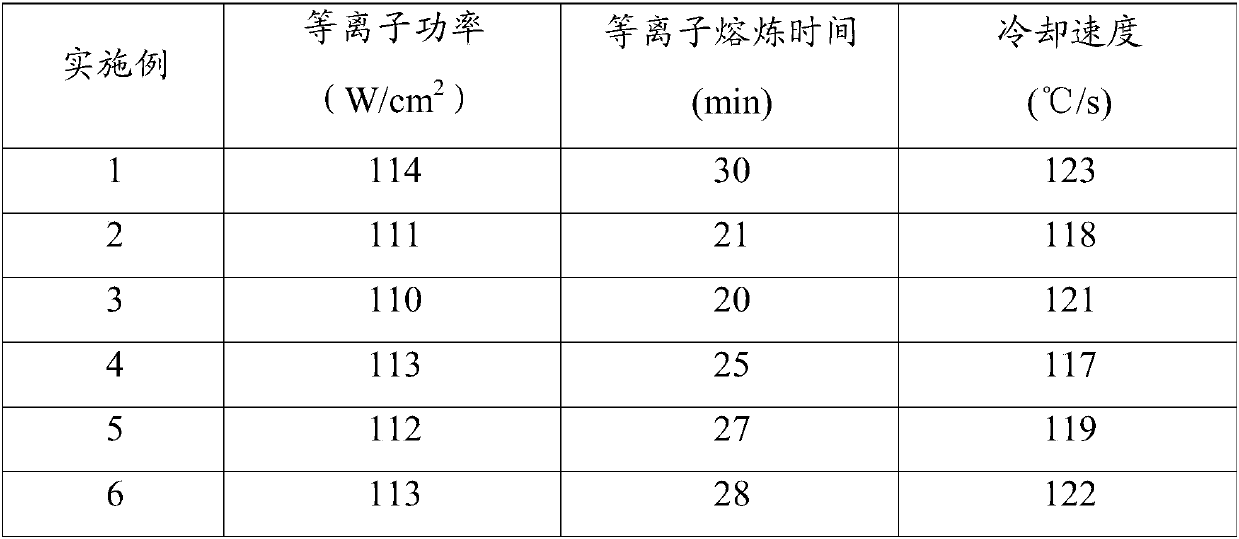

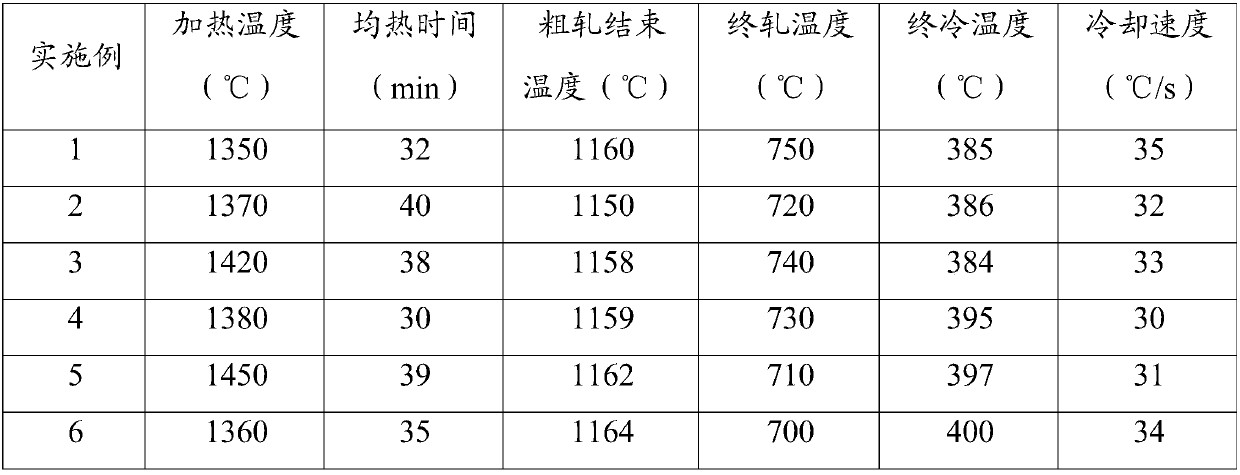

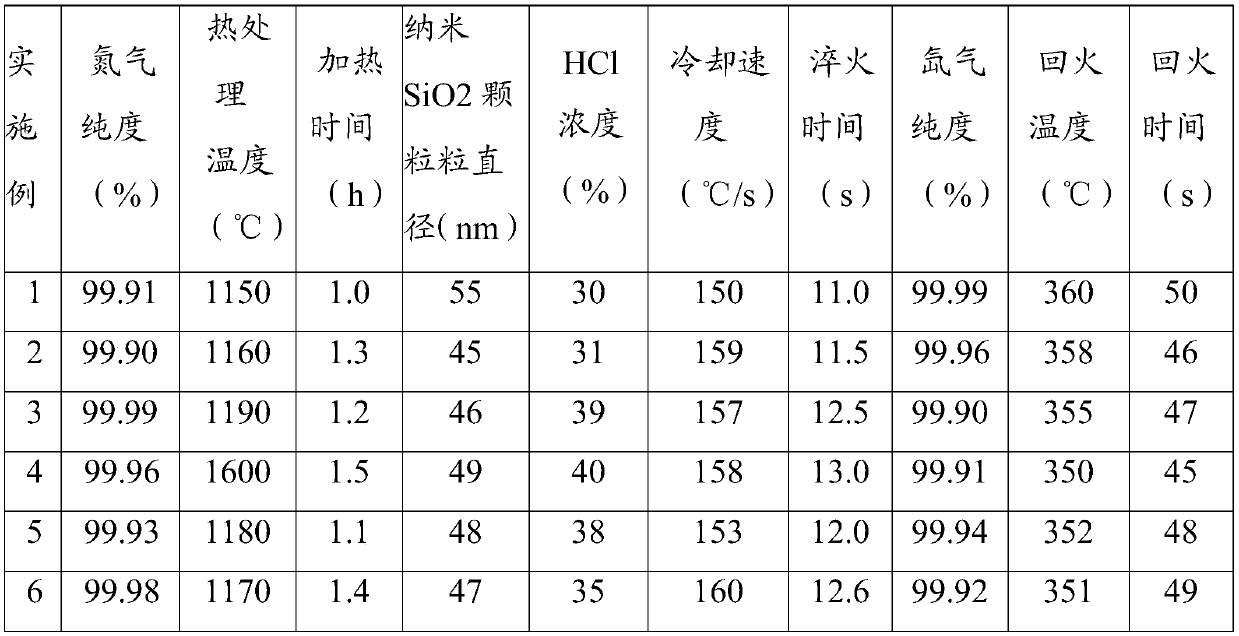

[0026] 2) The titanium-aluminum-boron shape memory alloy material is sequentially smelted, rolled, heat treated, quenched, tempered, and finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com