Split type tubular falling film evaporator

A falling film evaporator, split-type technology, applied in evaporator accessories, evaporation, multi-effect evaporation, etc., can solve the problems of affecting evaporation efficiency, insufficient layout area, occupying flash space, etc., and achieve flash evaporation area and space Expand and improve the flash evaporation effect and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

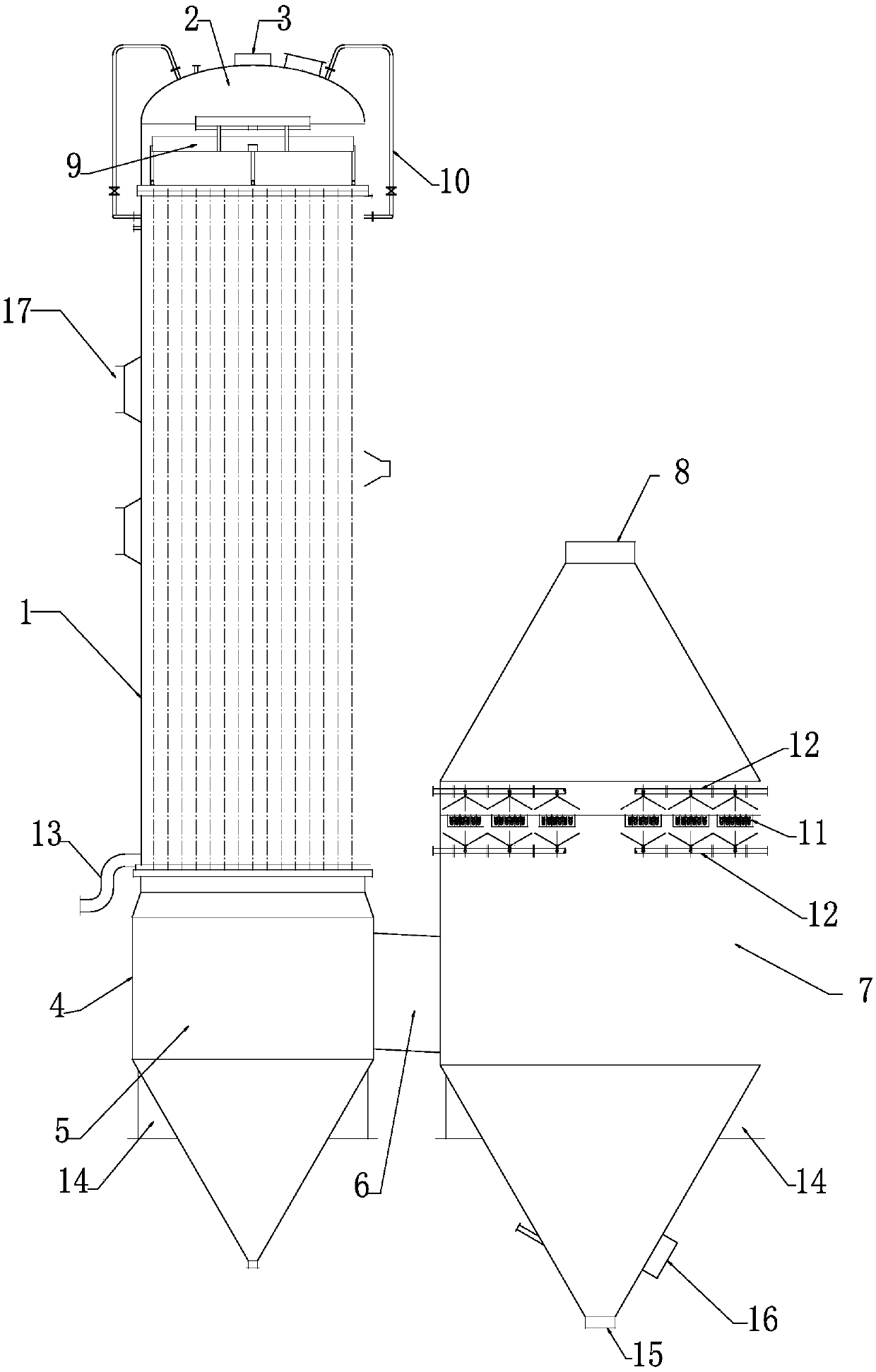

[0025] Such as figure 1 As shown, the split-type tubular falling-film evaporator includes a tubular falling-film heater 1, a dome-shaped upper cover 2 is connected to the upper end of the tubular falling-film heater 1 through a flange, and a solution inlet 3 is arranged on the top of the upper cover 2 The side wall of the tubular falling film heater 1 is provided with several steam inlets 17 communicating with the shell side, and the lower end of the tubular falling film heater 1 is connected with a cylindrical liquid collector 4 through a flange. The inside of the device 4 is a liquid collection chamber 5 connected to the tube side of the tubular falling film heater 1. A connecting pipe 6 communicating with the liquid collecting chamber 5 is connected to the side wall of the liquid collector 4. The other end of the connecting pipe 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com