A Roll Surface Roughness Strengthening and Optimal Control Method

A roll surface optimization control technology, applied in the field of metal material surface deformation strengthening, roll manufacturing, can solve the problems of insufficient wear resistance, uneven distribution of roll surface roughness, low holding force, etc., to improve the quality of strips, Effect of enhancing roughness retention ability and wear resistance, and improving rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

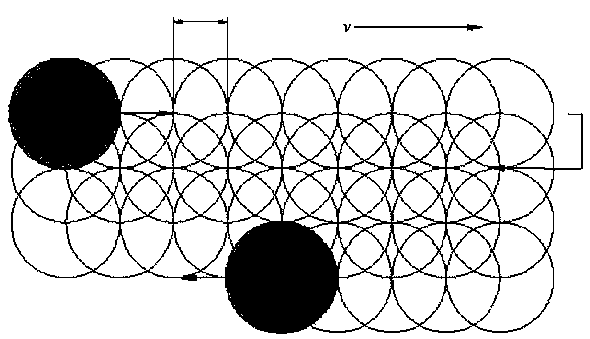

Method used

Image

Examples

Embodiment 1

[0036] Select a cast steel cylindrical hot-rolled billet with a diameter of 40 cm and a length of 100 cm. First, the surface of the billet is subjected to ultrasonic shock roughening treatment. The moving speed is 80cm / min, the single impact energy is 0.01J, the radius of curvature of the impact end is 0.1mm, the cutting amount is 0.3mm / r, the roll speed is 10r / min, and the surface roughness of the roll is about 0.05μm; secondly, the electroless plating process is used to plate Cr on the surface of the roll, and the coating is about 0.5mm; then, the Cr-plated layer on the surface of the roll is subjected to severe deformation treatment using an ultrasonic impact device, and the process parameter is that the ultrasonic impact frequency along the Z-axis direction is 100 times / second, the moving speed of the impact end along the X axis is 5cm / min, the impact energy is 0.5J; the radius of curvature of the impact end is 0.5mm; the cutting amount is 0.1mm / r, the roll speed is 2r / min,...

Embodiment 2

[0039] Select a cast iron H-type hot-rolled billet with a diameter of 40 cm and a length of 100 cm. First, the surface of the billet is subjected to ultrasonic shock roughening treatment. The speed is 80cm / min, the single impact energy is 0.1J, the radius of curvature of the impact end is 0.5mm, the cutting speed is 0.7mm / r, the roll speed is 30r / min, and the surface roughness of the roll after ultrasonic shock roughening is about 0.02 μm; secondly, use the hot dipping process to dip Al on the surface of the roll, and the coating is about 1mm; then use the ultrasonic impact device to perform severe deformation treatment on the surface of the roll coated with the Al layer, and the process parameters are: the ultrasonic impact frequency along the Z-axis direction is 1000 times per second, the moving speed of the impact end along the X axis is 20cm / min, the impact energy is 2J; the radius of curvature of the impact end is 1mm; the cutting amount is 0.2mm / r, the roll speed is 8r / mi...

Embodiment 3

[0042] Select a forged steel I-shaped cold roll billet with a diameter of 40 cm and a length of 100 cm. First, the surface of the billet is subjected to ultrasonic shock roughening treatment. The moving speed of the shaft is 40cm / min, the single impact energy is 0.03J, the radius of curvature of the impact end is 0.31mm, the cutting distance is 0.5mm / r, the roll speed is 18r / min, and the surface roughness of the roll is about The thickness is 0.04μm; secondly, the surface of the roll is coated with Ti by spraying process, and the coating is about 0.77mm; then, the Ti layer coated on the surface of the roll is subjected to severe deformation treatment using an ultrasonic impact device, and the process parameter is that the ultrasonic impact frequency is along the Z axis The direction is 230 times / second, the moving speed of the impact end along the X axis is 12cm / min, the impact energy is 1.5J; the radius of curvature of the impact end is 0.68mm; the cutting amount is 0.17mm / r, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com