A kind of preparation method of micro tool electrode

A tool electrode and electrode technology, which is applied in the field of preparation of micro tool electrodes, can solve the problems of low processing efficiency and insignificant improvement of processing efficiency, and achieve the effects of improving the corrosion rate, increasing the electrolysis reaction area, and improving the preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

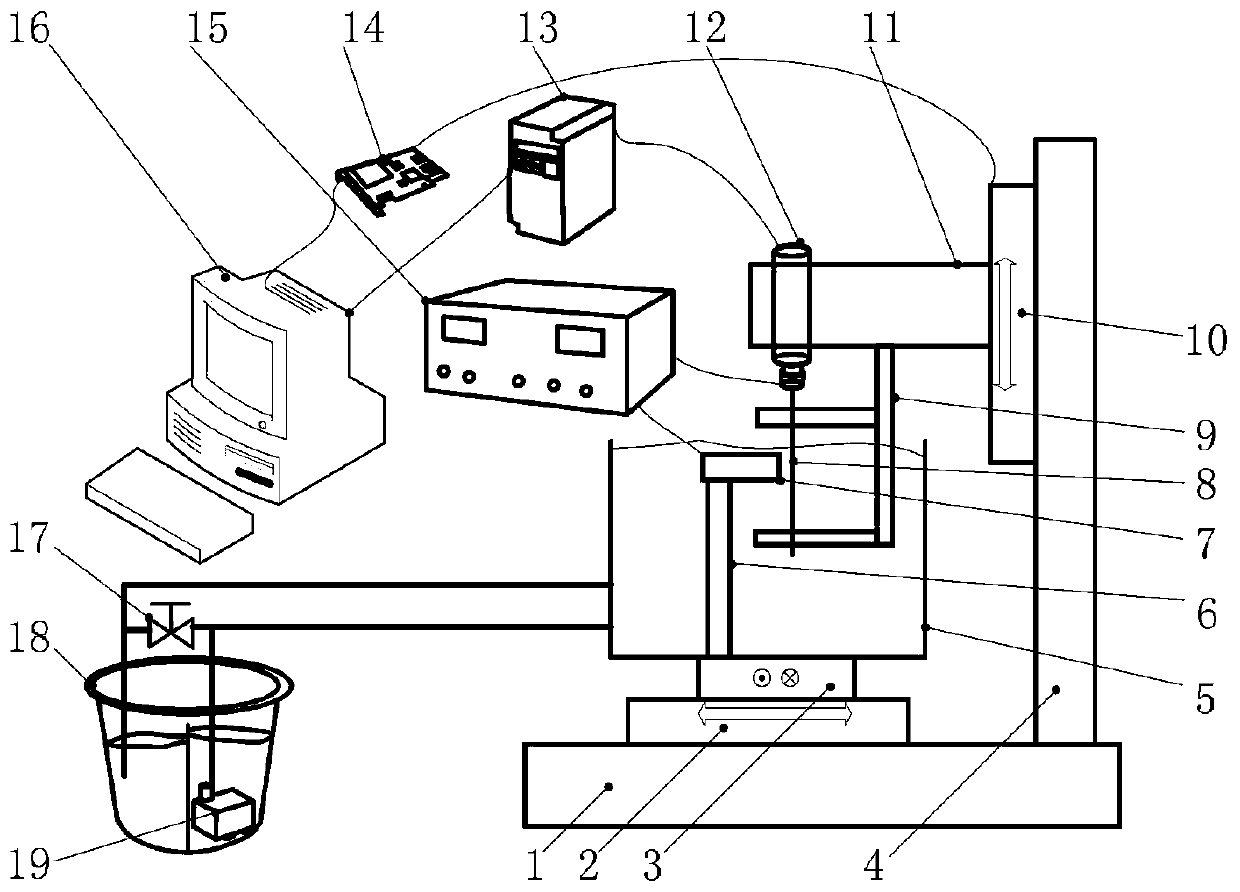

[0052] Such as figure 1 As shown, the preparation device for the micro-tool electrode provided in this embodiment includes: a base platform 1 and a column 4 vertically fixed on one end of the base platform 1; Shaft 10, one end of connecting rod 11 is fixed at the middle position of motion shaft 10, the other end of connecting rod 11 is installed electric spindle 12, the lower surface of connecting rod 11 is fixed fixture 9, fixture 9 has two upper and lower arms, electric spindle 12 And the clamp 9 is used to fix the rod-shaped electrode 8 to be processed; the motion shaft 2 that drives the block electrode 7 along the linear direction perpendicular to the central axis of the electric spindle 12 is set on the base platform 1, above the motion shaft 2 The motion shaft 3 is set, the motion direction of the motion shaft 3 is perpendicular to the direction of the feed motion, the upper surface of the motion shaft 3 fixes the electrolytic cell 5, the block electrode 7 is fixed on th...

Embodiment 2

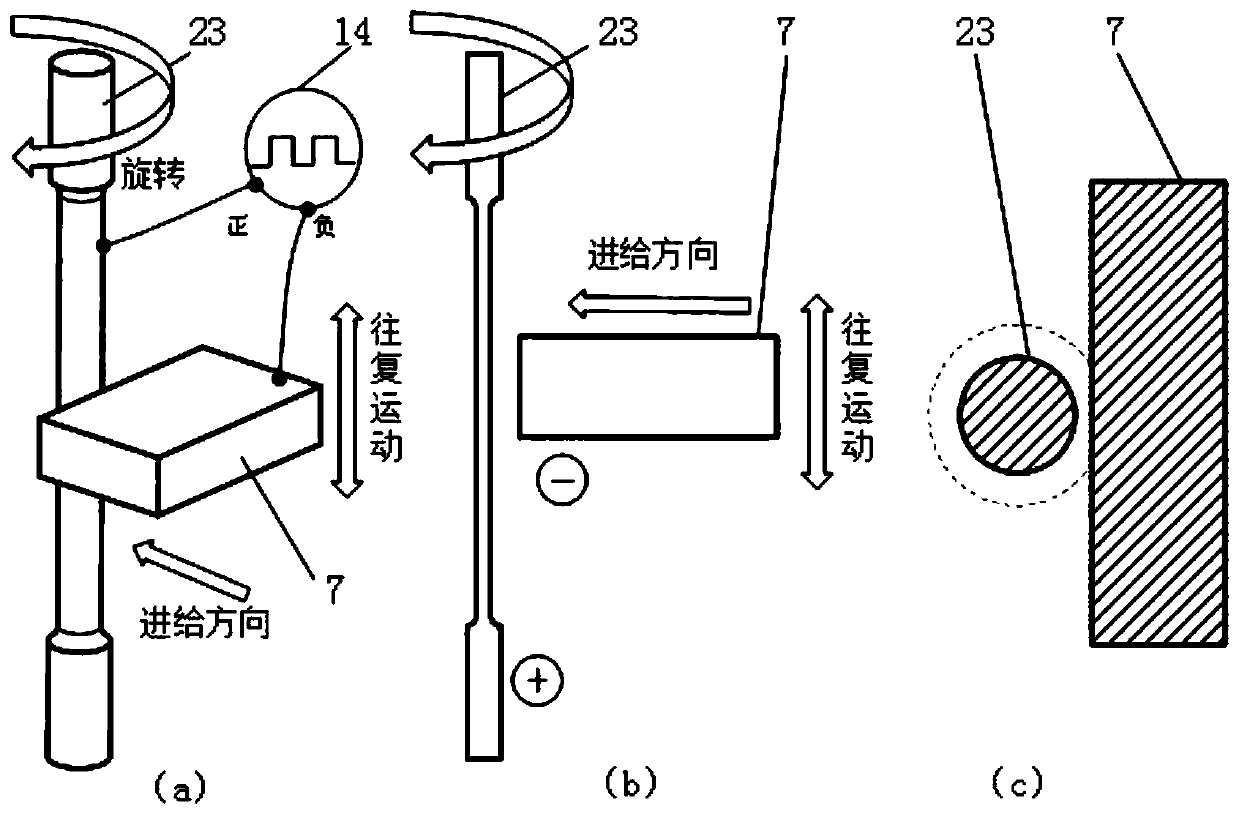

[0083] Such as Figure 4 as shown, Figure 4 (a) is a three-dimensional schematic diagram of the processed rod electrode, Figure 4 (b) is a schematic plan view of the processed rod electrode, Figure 4 (c) is a cross-sectional view of the processed rod electrode.

[0084] The control program of machining edge-cutting electrode 24 comprises:

[0085] Adjusting the distance between the block electrode 7 and the rod-shaped electrode 8 to be processed according to the preset initial processing gap;

[0086] Control the rod-shaped electrode 8 to be processed to reciprocate up and down in the vertical direction;

[0087] The block electrode 7 is controlled to perform a feed motion along a straight line perpendicular to the central axis of the electric spindle 12 .

[0088] According to the control program, a certain width is electrolytically cut on the rod-shaped electrode 8 to be processed, and the processing of a finely edge-cut electrode 23 is completed.

Embodiment 3

[0090] Figure 5 For the schematic diagram of the process of electrolytically preparing the probe electrode, the control program for processing the probe electrode 21 and the probe electrode 22 includes:

[0091] Adjusting the distance between the block electrode 7 and the rod-shaped electrode 8 to be processed according to the preset initial processing gap;

[0092] Control the rod-shaped electrode 8 to be processed to perform up-and-down reciprocating motion along the vertical direction and rotational motion centered on the central axis of the electric spindle 12 at the same time, such as Image 6 As shown in (b), the speed curve of the rod-shaped electrode 8 to be processed reciprocating up and down is a sinusoidal curve;

[0093] The block electrode 7 is controlled to perform a feed motion along a straight line perpendicular to the central axis of the electric spindle 12 .

[0094] Because the speed of the rod-shaped electrode 8 to be processed is very slow at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com