Electrical discharge machining method achieving uneven distribution of single pulse energy of pulse power source

A non-uniform distribution and pulse energy technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of tool electrode loss, slowness, and workpiece surface quality deterioration, etc., to achieve increased erosion rate and reasonable power supply Energy, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

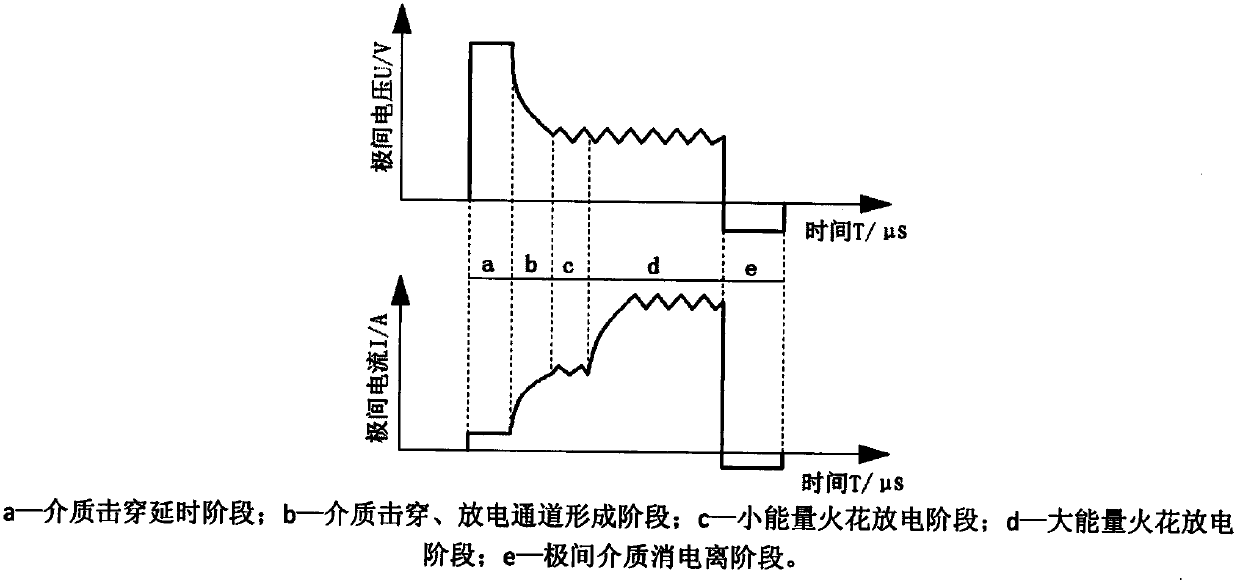

[0026] Such as figure 1 , 2 shown.

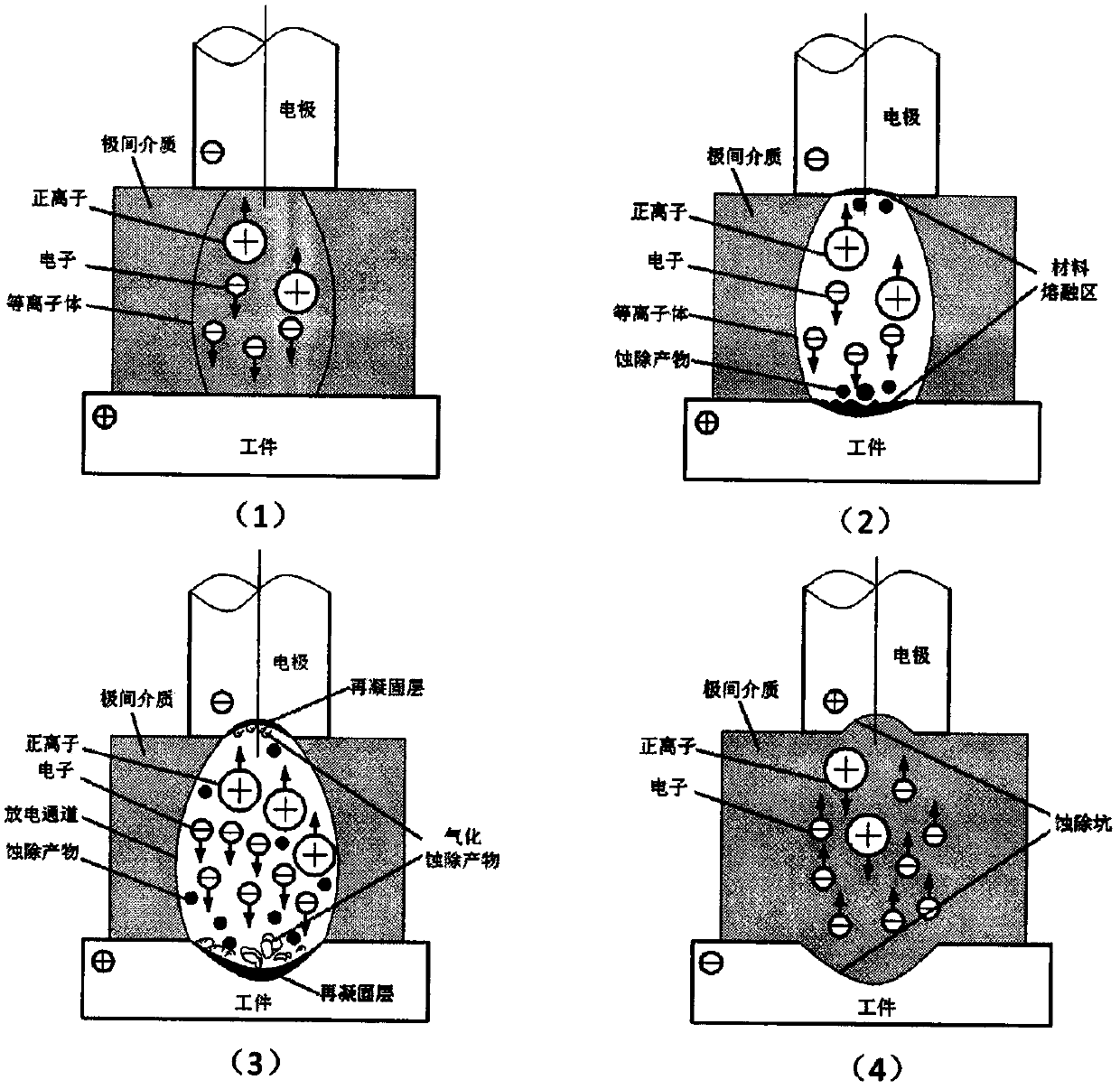

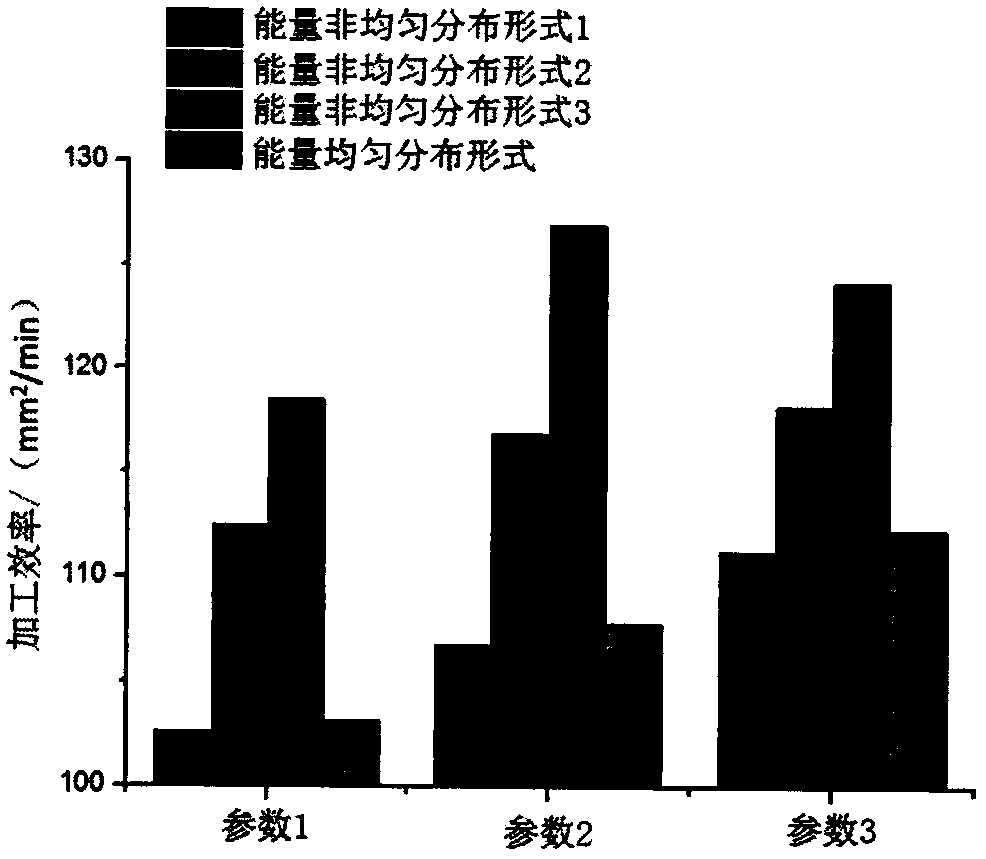

[0027]A method to improve the energy utilization rate and processing effect of a pulse power supply by changing the energy distribution in a single pulse, aiming at the following purposes in the EDM process to reasonably distribute the energy of a single pulse: further excavate the energy utilization rate of the power supply pulse and improve the processing efficiency , speed up the deionization speed between the electrodes after the discharge, reduce the thickness of the solidified layer on the processed surface, and improve the integrity of the processed surface. Including the following energy distribution content:

[0028] (1) The ionization and breakdown stages of the interpolar medium

[0029] After the pulse voltage is applied between the tool electrode and the workpiece, an electric field is formed between the two electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com