Extraction method for preparing high-quality phosphoric acid from hydrochloric-acid-process wet-process phosphoric acid

A wet-process phosphoric acid, high-quality technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of large equipment investment, low yield, large equipment occupation, etc., achieve short construction time, increase income The effect of high efficiency and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

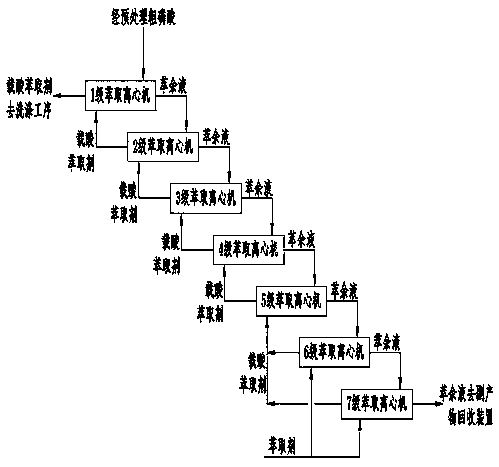

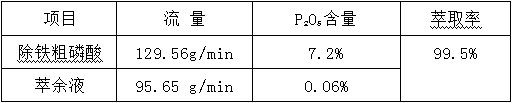

[0030] Embodiment 1: Take a 6-stage extraction centrifuge as an example.

[0031] An extraction method for preparing high-quality phosphoric acid by hydrochloric acid wet-process phosphoric acid, the steps of which are:

[0032] (1) Acid leaching: Phosphate rock powder and industrial by-product hydrochloric acid with a concentration of 20-24wt% after preparation are fully reacted in the reaction tank to obtain phosphoric acid slurry; the excess hydrochloric acid is 5% (calculated as calcium oxide in phosphate rock);

[0033] (2) Press filtration and washing: the phosphoric acid slurry is filtered and washed by a filter press to obtain the filtrate, that is, crude phosphoric acid, and the washing solution is returned to the acid leaching section to prepare hydrochloric acid, and the filter cake is treated in a centralized manner;

[0034] (3) Pre-extraction iron removal: crude phosphoric acid is extracted with an organic extractant to remove iron, and the obtained iron-removed ...

Embodiment 2

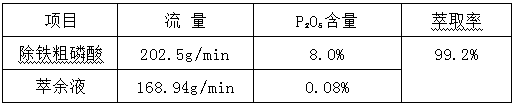

[0041] Embodiment 2: Take an 8-stage extraction centrifuge as an example.

[0042] (1) Acid leaching: Phosphate rock powder and industrial by-product hydrochloric acid with a concentration of 20-24wt% after preparation are fully reacted in the reaction tank to obtain phosphoric acid slurry; the excess hydrochloric acid is 5% (calculated as calcium oxide in phosphate rock);

[0043] (2) Press filtration and washing: the phosphoric acid slurry is filtered and washed by a filter press to obtain the filtrate, that is, crude phosphoric acid, and the washing solution is returned to the acid leaching section to prepare hydrochloric acid, and the filter cake is treated in a centralized manner;

[0044] (3) Pre-extraction iron removal: crude phosphoric acid is extracted with an organic extractant to remove iron, and the obtained iron-removed crude phosphoric acid enters the extraction section;

[0045] (4) Extraction: P removal from iron crude phosphoric acid 2 o 5 The content is 8%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com