A kind of seawater-based fracturing fluid and its preparation method and application

A seawater and base pressure technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problem that the temperature resistance is difficult to meet the application requirements and improve, and achieve good sand-carrying performance and good breaking capacity. Adhesive properties, the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

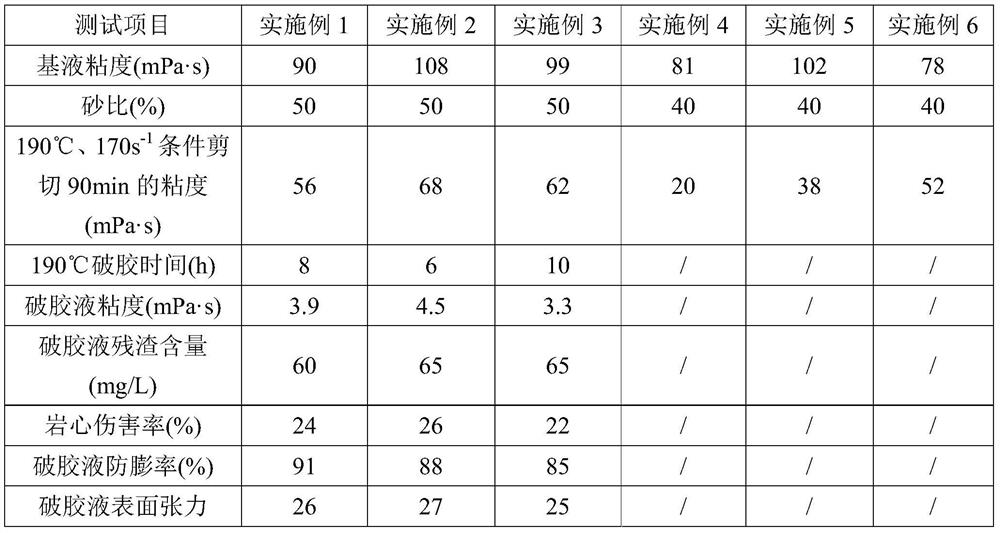

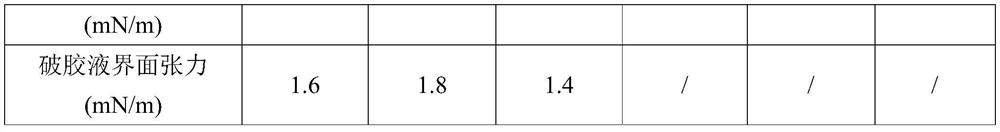

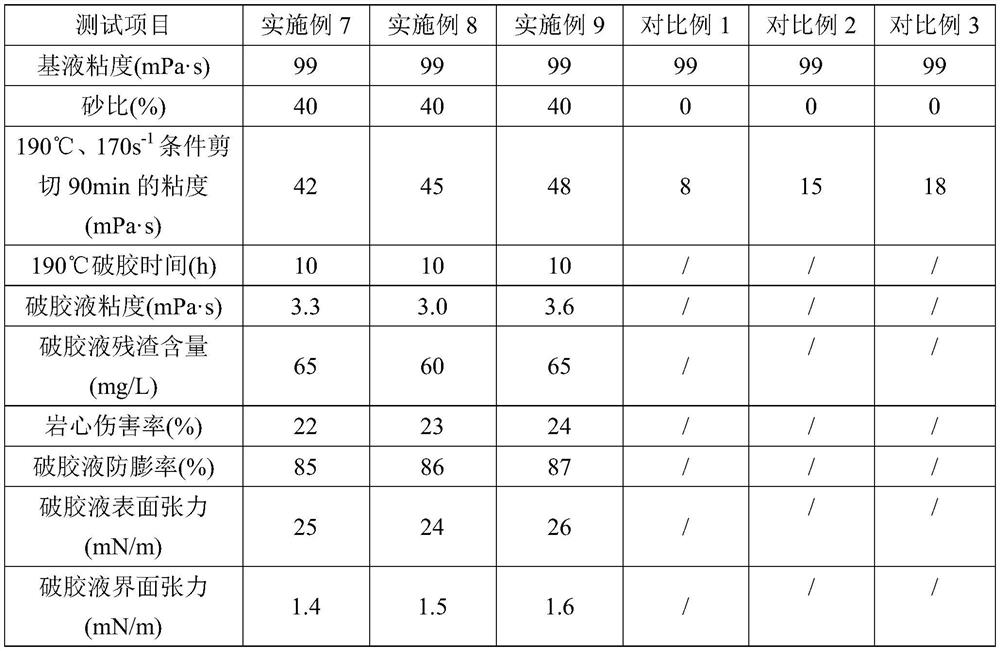

Embodiment 1

[0051] This embodiment provides a seawater-based fracturing fluid, including a base fluid and a cross-linking agent accounting for 0.1% by weight of the base fluid, and the base fluid includes the following components in weight percentage:

[0052] Seawater-based fracturing fluid thickener 0.8%, performance regulator 0.6%, chelating agent 0.8%, high temperature stabilizer 0.2%, anti-swelling agent 1%, drainage aid 0.04%, gel breaker 0.1%, the balance is seawater ;

[0053] Wherein, the seawater-based fracturing fluid thickener is the high-temperature-resistant seawater-based fracturing fluid thickener disclosed in Example 1 of CN 108485640A;

[0054] The performance regulator is prepared by the following method: keep the temperature in the reactor at 30°C, add 310g of deionized water, 125g of acrylamide, 50g of sodium acrylate, 5g of allyloxysodium dodecyl carboxylate and 10g of 2-Acrylamido sodium dodecylsulfonate, stir until dissolved, then pass 99.999% high-purity nitrogen...

Embodiment 2

[0064] This embodiment provides a seawater-based fracturing fluid, including a base fluid and a crosslinking agent accounting for 0.14% by weight of the base fluid, and the base fluid includes the following components in weight percentage:

[0065]Seawater-based fracturing fluid thickener 1.2%, performance regulator 0.4%, chelating agent 0.5%, high temperature stabilizer 0.3%, anti-swelling agent 0.8%, drainage aid 0.02%, gel breaker 0.3%, the balance is seawater ;

[0066] Wherein, the seawater-based fracturing fluid thickener is the high-temperature resistant seawater-based fracturing fluid thickener disclosed in Example 2 of CN 108485640A;

[0067] The performance modifier is prepared by the following method: keep the temperature in the reactor at 30°C, add 236g of deionized water, 120g of acrylamide, 32g of sodium acrylate, 8g of allyloxysodium dodecyl carboxylate and 4g of Sodium 2-acrylamido dodecylsulfonate, stirred until dissolved, then passed 99.999% high-purity nitr...

Embodiment 3

[0077] This embodiment provides a seawater-based fracturing fluid, including a base fluid and a cross-linking agent accounting for 0.12% by weight of the base fluid, and the base fluid includes the following components in weight percentage:

[0078] Seawater-based fracturing fluid thickener 1%, performance regulator 0.5%, chelating agent 1%, high temperature stabilizer 0.4%, anti-swelling agent 0.5%, drainage aid 0.06%, gel breaker 0.2%, the balance is seawater ;

[0079] Wherein, the seawater-based fracturing fluid thickener is the high-temperature resistant seawater-based fracturing fluid thickener disclosed in Example 3 of CN 108485640A;

[0080] The performance regulator is prepared by the following method: keep the temperature in the reactor at 30°C, add 180g of deionized water, 84g of acrylamide, 27g of sodium acrylate, 4.5g of allyloxydodecyl sodium carboxylate and 4.5g 2-acrylamido sodium dodecylsulfonate, stir until dissolved, then pass 99.999% high-purity nitrogen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com