Preparation method of asparagus agar oligosaccharide

A technology of agar oligosaccharides and asparagus, which is applied in the field of oligosaccharide production, can solve the problems of low extraction rate of agar, low activity of beneficial bacteria, environmental pollution, etc., and achieve improved extraction rate of agar, high activity of beneficial bacteria, The effect of high antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

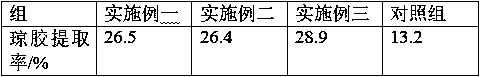

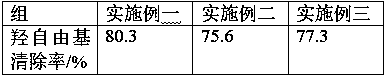

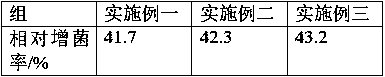

Examples

Embodiment 1

[0026] The present invention is a kind of preparation method of asparagus agar oligosaccharide, comprising the following steps:

[0027] (1) After soaking asparagus in salt water for 3 hours, wash, dry and sterilize;

[0028] (2) Crushing the asparagus tubers in a grinder, extruding and filtering through a filter screen with a mesh number of 100 mesh to obtain asparagus vegetable puree;

[0029] (3) Add asparagus vegetable puree to water, the mass ratio of asparagus vegetable puree to water is 1:21, mix well and then heat, and heat at 105°C for 90 minutes to obtain a water extraction mixture;

[0030] (4) Microwave heating the water-extraction mixture, the microwave heating power is high, and the microwave heating is intermittent heating, heating for 1 minute, stopping for 4 minutes, repeating 3 times, and then extruding the gel to obtain an agar solution;

[0031] (5) Cool the agar solution to room temperature and add a buffer to make the pH of the agar solution 6, then add ...

Embodiment 2

[0034] The present invention is a kind of preparation method of asparagus agar oligosaccharide, comprising the following steps:

[0035] (1) After soaking asparagus in salt water for 5 hours, wash, dry and sterilize;

[0036] (2) Break the asparagus tubers in a grinder, squeeze and filter through a filter screen with a mesh number of 150 mesh, and obtain asparagus vegetable puree:

[0037] (3) Add asparagus vegetable puree to water, the mass ratio of asparagus vegetable puree to water is 1:26, mix well and then heat, and heat at 115°C for 105min to obtain the water extraction mixture;

[0038] (4) Microwave heating the water-extraction mixture, the microwave power is medium heat, and the microwave heating is intermittent heating, heating for 2 minutes, stopping for 6 minutes, repeating 5 times, and then extruding the gel to obtain an agar solution;

[0039] (5) Cool the agar solution to room temperature and add a buffer to make the pH of the agar solution 8, then add β-agaras...

Embodiment 3

[0042] The present invention is a kind of preparation method of asparagus agar oligosaccharide, comprising the following steps:

[0043] (1) After soaking asparagus in salt water for 4 hours, wash, dry and sterilize;

[0044] (2) Break the asparagus tubers in a grinder, squeeze and filter through a filter screen with a mesh number of 120 mesh, and obtain asparagus vegetable puree:

[0045] (3) Add asparagus vegetable puree to water, the mass ratio of asparagus vegetable puree to water is 1:24, mix well and then heat, and heat at 110°C for 100 minutes to obtain a water extraction mixture;

[0046] (4) Microwave heating the water-extraction mixture, the microwave power is medium heat, high heat, microwave heating is intermittent heating, heating for 1.5min, stopping for 5min, repeating 4 times, and then extruding the gel to obtain the agar solution ;

[0047] (5) Cool the agar solution to room temperature and add a buffer to make the pH of the agar solution 7, then add β-agara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com