Novel mold manufacturing technology

A manufacturing process and new mold technology, applied in the field of new mold manufacturing process, can solve the problems of inability to monitor the manufacturing process in real time, the service life of the mold is not high, and the process flow is complicated, and achieve the effect of qualified hardness, high pass rate and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

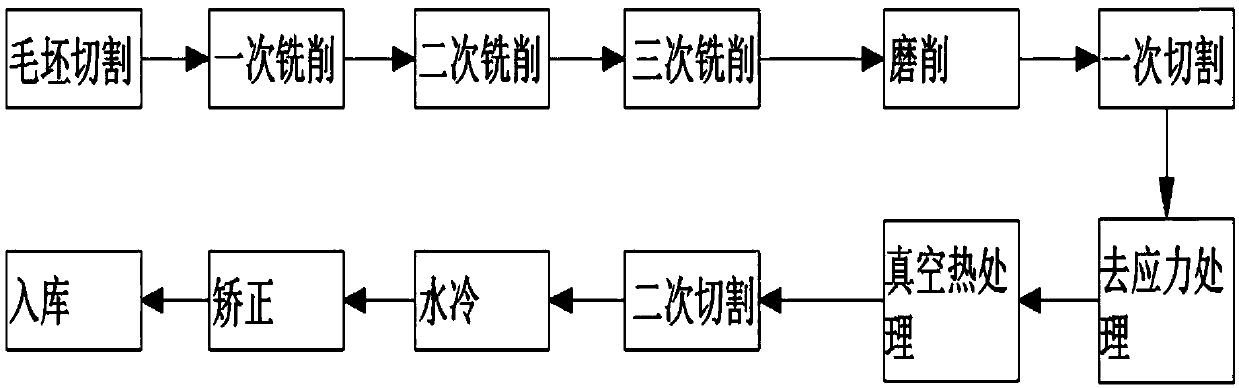

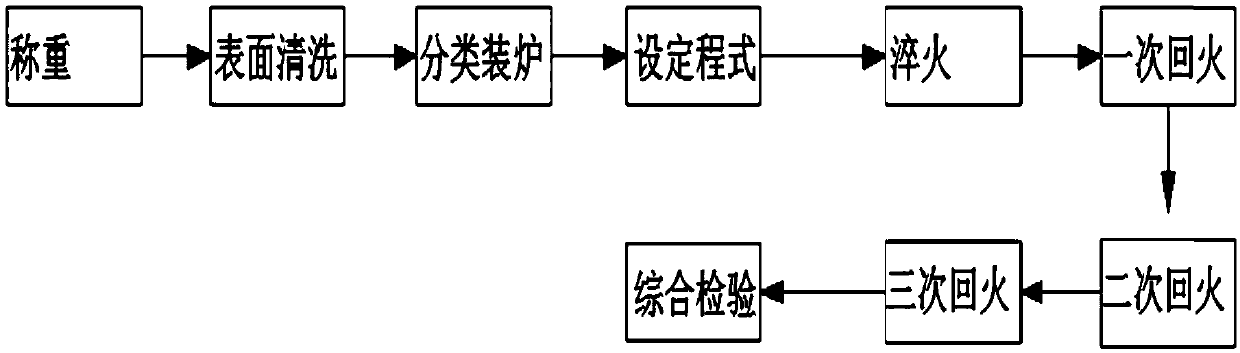

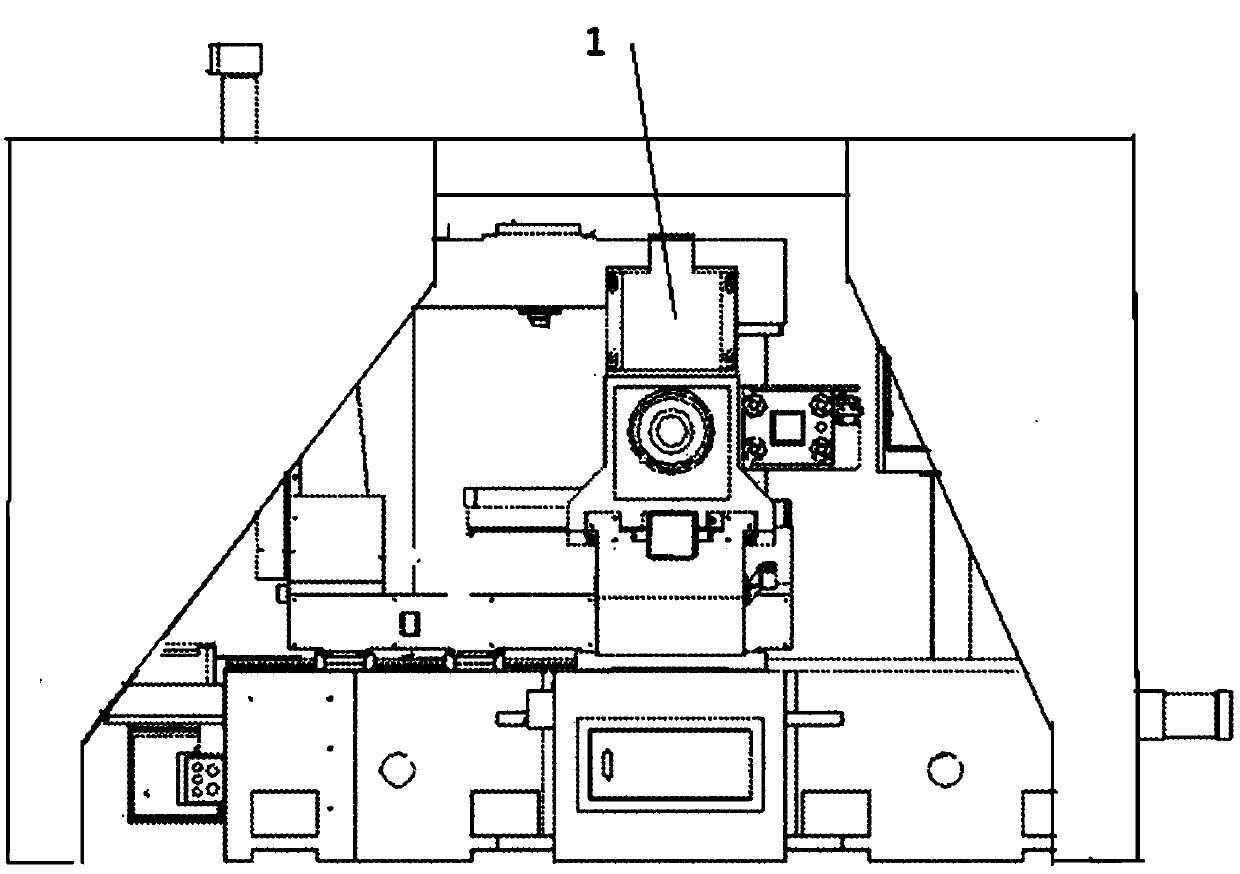

[0026] Such as Figure 1 to Figure 3 As shown, a new mold manufacturing process, the specific steps include: blank cutting, milling, grinding, cutting, stress relief treatment, vacuum heat treatment, cutting, water cooling, straightening, storage. Rough cutting cuts the raw material to obtain a mold block suitable for machining. Milling includes primary milling, secondary milling, and tertiary milling; primary milling roughs the surface of the raw material, secondary milling processes forming holes, and tertiary milling finishes the mold. After three milling operations, a mold with a precision that meets the requirements is obtained. At this time, the mold has the required holes and grooves, and then it is ground to make the surface roughness of the mold meet the requirements. The mold is preliminarily completed and the mold at this point is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com