WC-Co nano-reinforced high-silicon aluminum alloy for electric connecting fitting and preparation method of WC-Co nano-reinforced high-silicon aluminum alloy

A high-silicon aluminum alloy and nano-reinforcement technology, which is applied in the field of high-silicon aluminum alloy reinforcement, can solve the problems of coarse microstructure grains, affecting the mechanical properties of electrical connection fittings materials, and weak tensile strength of alloys, etc., to achieve superior density , strong practical significance, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

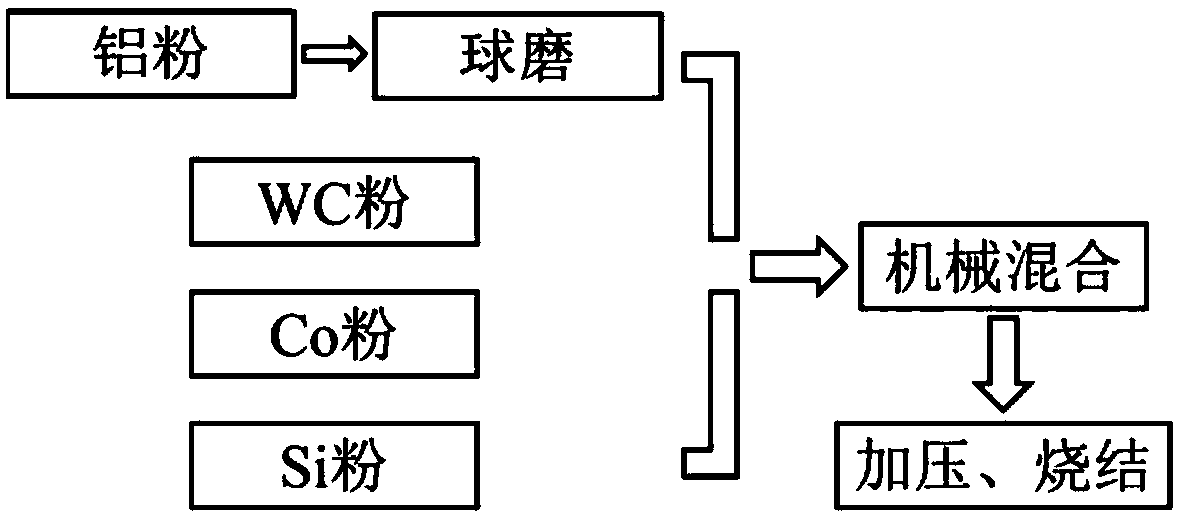

Method used

Image

Examples

Embodiment 1

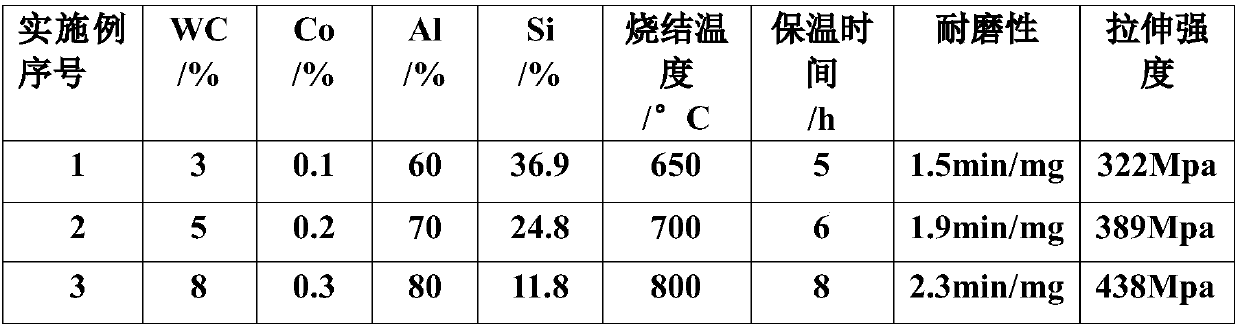

[0029] (1) As a limitation to the present invention, the composition ratio of WC-Co nano-reinforced high-silicon aluminum alloy used in the present invention is: 3.0% WC, 0.1% Co, 60% Al, 36.9% Si, and the balance is unavoidable of impurities. Among them, the particle size of WC powder is 3 μm, the grain size is 200 nm, the particle size of Co powder is 2 μm, the particle size of Al powder is 75 μm, and the particle size of Si powder is 75 μm.

[0030] (2) Put the Al powder into a ball mill and mill it for 12 hours, the ball-to-material ratio is 10:1, the ball milling speed is 200r / min, and high-purity Ar gas is used as the protective atmosphere to destroy the surface oxide layer of the Al powder, and then the Distribution ratio Mix 3.0% WC, 0.1% Co, 60% Al, 36.9% Si on the mixer for 30-60min, mix evenly, then put the mechanically mixed powder into the mold for pressing, the molding pressing pressure is 500MPa, The holding time is 1-3min, put it into a rapid heating electric ...

Embodiment 2

[0032] (1) The composition ratio of the WC-Co nano-reinforced high-silicon aluminum alloy used is: 5.0% WC, 0.2% Co, 70% Al, 24.8% Si, and the balance is unavoidable impurities. Among them, the particle size of WC powder is 3 μm, the grain size is 200 nm, the particle size of Co powder is 2 μm, the particle size of Al powder is 75 μm, and the particle size of Si powder is 75 μm.

[0033] (2) Put the Al powder into a ball mill and mill it for 12 hours, the ball-to-material ratio is 10:1, the ball milling speed is 200r / min, and high-purity Ar gas is used as the protective atmosphere to destroy the surface oxide layer of the Al powder, and then the The distribution ratio is 5.0% WC, 0.2% Co, 70% Al, 24.8% Si, and the balance is unavoidable impurities. Mix on the mixer for 45min, mix evenly, then put the mechanically mixed powder into the mold for pressurization, the molding pressing pressure is 500MPa, the holding time is 3min, put it into the rapid heating electric furnace for s...

Embodiment 3

[0035] (1) The composition ratio of the WC-Co nano-reinforced high-silicon aluminum alloy used is: 8.0% WC, 0.3% Co, 80% Al, 11.8% Si, and the balance is unavoidable impurities. Among them, the particle size of WC powder is 3 μm, the grain size is 200 nm, the particle size of Co powder is 2 μm, the particle size of Al powder is 75 μm, and the particle size of Si powder is 75 μm.

[0036] (2) Put the Al powder into a ball mill and mill it for 12 hours, the ball-to-material ratio is 10:1, the ball milling speed is 200r / min, and high-purity Ar gas is used as the protective atmosphere to destroy the surface oxide layer of the Al powder, and then the Distribution ratio Mix 8.0% WC, 0.3% Co, 80% Al, 11.8% Si on the mixer for 45 minutes, mix evenly, then put the mechanically mixed powder into the mold for pressing, the molding pressing pressure is 500MPa, the holding time Put it into a rapid heating electric furnace for 3min for sintering, the sintering environment is under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com