A twisting device for polyester composite fibers

A composite fiber and polyester technology, which is applied in the direction of continuous winding spinning machines, textiles, papermaking, yarn, etc., can solve the problems of uneven texture, low strength, and insufficient effect of polyester composite yarns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

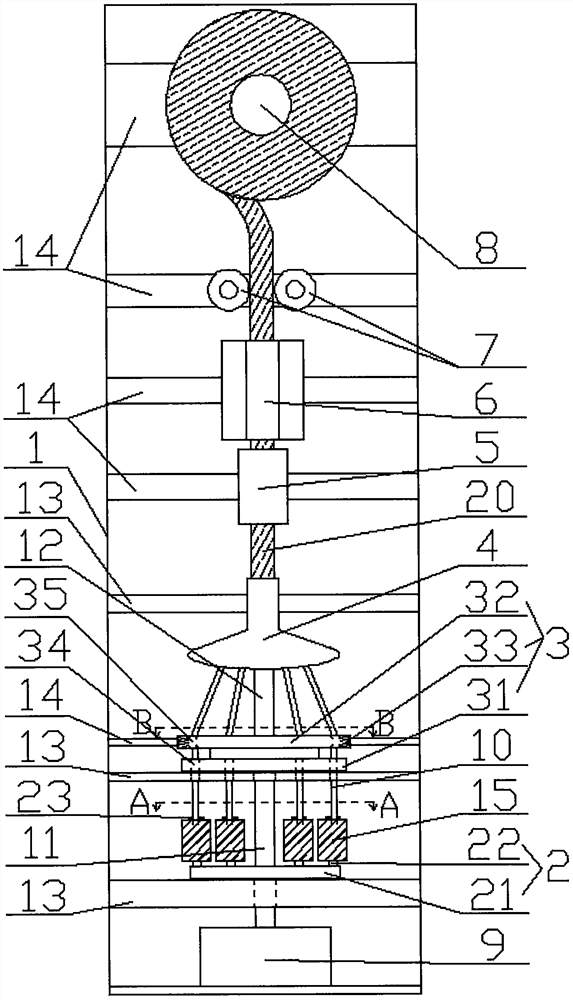

[0031] Such as figure 1 , figure 2 and image 3 A twisting device for polyester composite fibers shown includes a heating mechanism 5, a cooling mechanism 6, a discharge roller 7 and a winding roller 8 arranged in sequence, and is characterized in that it also includes a coil turntable 2 arranged in sequence , a self-twisting mechanism 3 and a thread-combining cylinder 4, and the output end of the thread-combining cylinder 4 is connected to the input end of the heating mechanism 5, and each of the above-mentioned mechanism components is arranged on a vertical support seat 1,

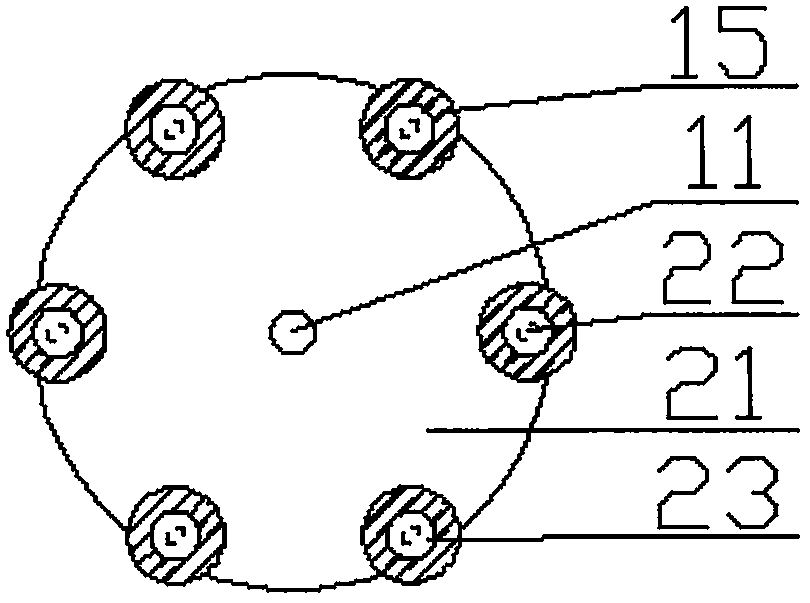

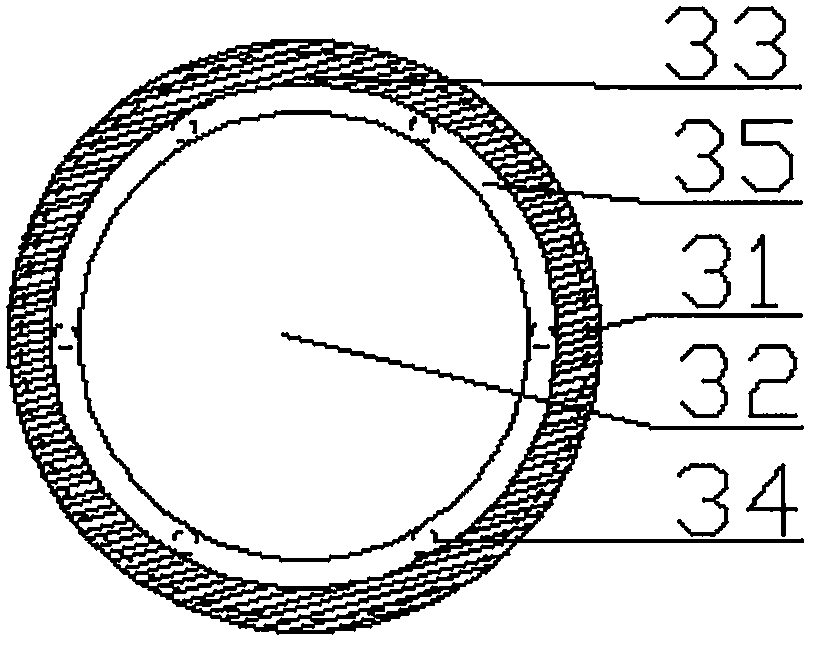

[0032] The coil rotating disk 3 includes a rotating disk 21 and at least two positioning cylinders 22 (in this embodiment, six positioning cylinders 22 are provided) that are uniformly distributed in a ring and fixed on the upper surface of the rotating disk 21; Twisting mechanism 3 comprises the silk thread limiting turntable 31 and the silk thread self-twisting turntable 32 that are fixed together i...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the structure of the line-combining cylinder is as follows: Figure 5 As shown, the threading cylinder 4 includes a conical part and a straight-through pipe part. The inner wall of the conical part is evenly provided with threading grooves 18 corresponding to the positioning cylinder 22 one by one, and the threading grooves 18 are connected to the cone along the generatrix The bottom and the top of the shaped part, and the middle part of the notch of each threading groove 18 is provided with a blocking piece 41; a thin connecting rod 19 is fixed on the threading cylinder 4 between each adjacent two threading grooves 18, The lower end of the thin connecting rod 19 is fixed on the upper end of the second connecting rod 12 . In application, the silk thread is attached to the inner wall of the thread-combining cylinder 4, so that the distance between the threads between the self-twisting mechanism 3 and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com