Multilayer tuned liquid damper for offshore wind power generation tower

A technology of tuning liquid damping and liquid, which is applied in wind power generation, installation/supporting configuration of wind turbines, wind turbines, etc. It can solve the problem that wind power towers and wind turbines are prone to damage, tuned liquid dampers only have a single layer, and change damping Improve the energy consumption effect, increase the shaking range, and increase the energy consumption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

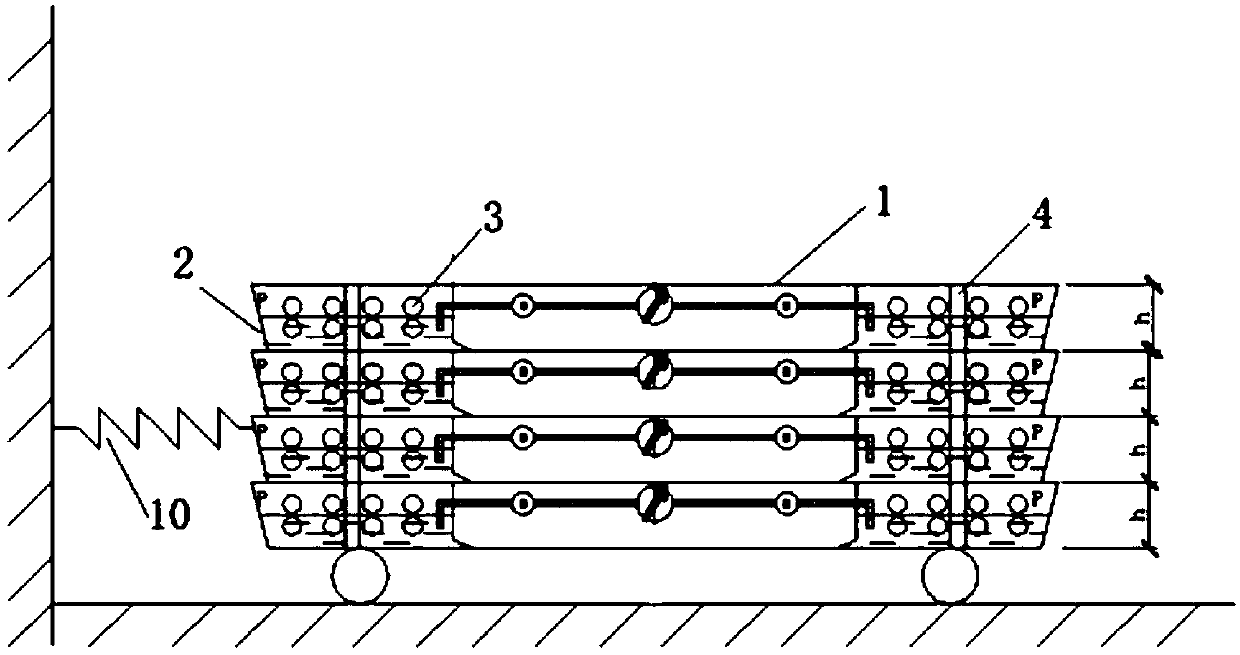

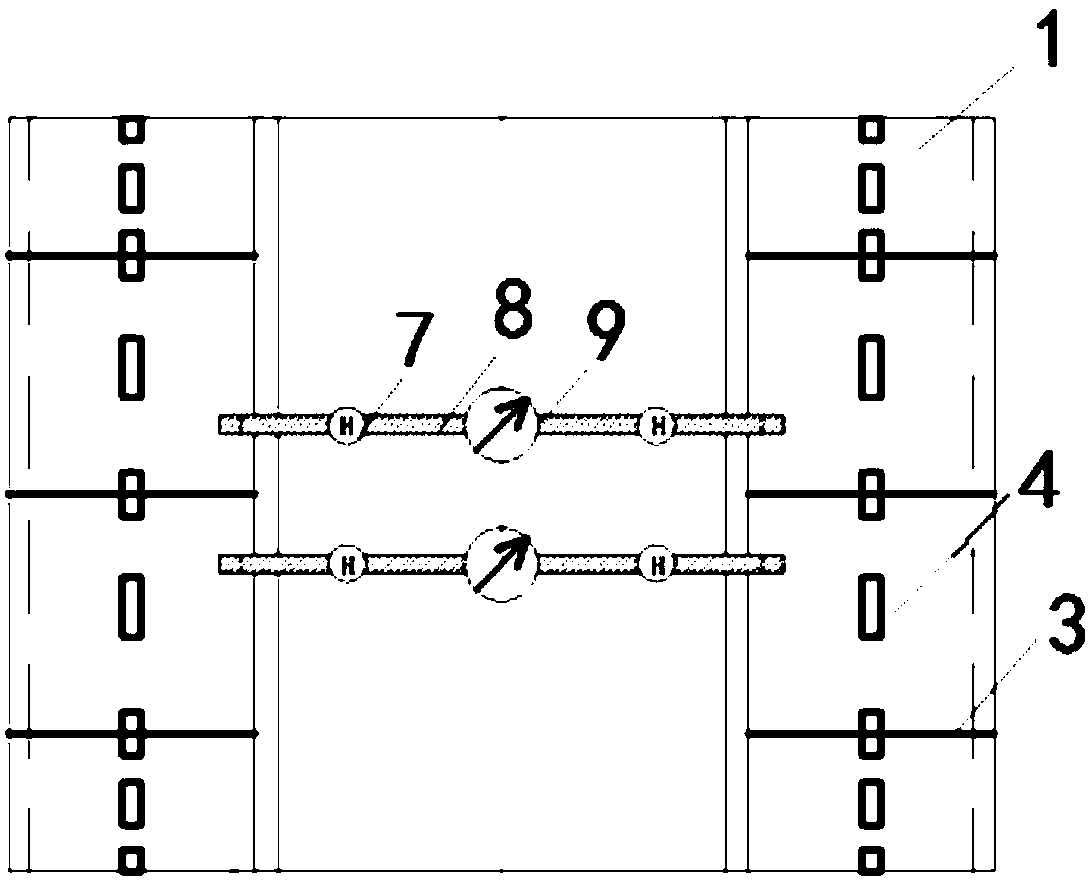

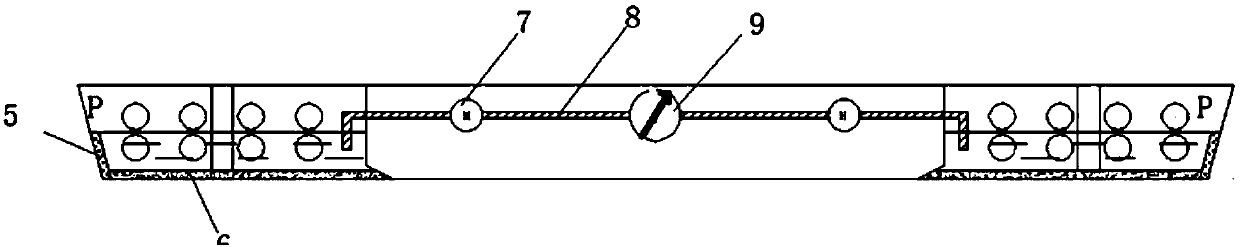

[0029] A multi-layer tuned liquid damper for offshore wind power towers, the structure of which is as follows Figure 1 ~ Figure 3 As shown, it mainly includes a damping cavity unit 1, a liquid 2, a thin steel sheet 3, a baffle 4, a friction material 5, a buffer material 6, a heater 7, a liquid pipeline 8, a hydraulic device 9, and a spring 10.

[0030] The damping cavity unit 1 is divided into 4 layers, and the damping cavity of each layer is isosceles trapezoidal, divided into left area, middle area and right area, and the left area and the right area are filled with liquid 2, but cannot be filled. The damping cavity unit 1 is fixed to the structure of the wind power generation tower through a spring 10 . Each damping cavity has built-in thin steel sheets 3 and baffles 4, which can be fixed inside the damping cavity by welding, and are uniformly arranged at equal angles. The specific number can be obtained through experiments. 3 thin steel sheets 3 and 9 baffle plates 4 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com