Secondary gas source protective magnetic pump device suitable for conveying particle-containing impurity medium

A particle impurity, magnetic pump technology, applied in the parts of pumping devices for elastic fluids, pump devices, pumps for special fluids, etc., to solve the need for forced lubrication, improve efficiency, and have good self-lubricating effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

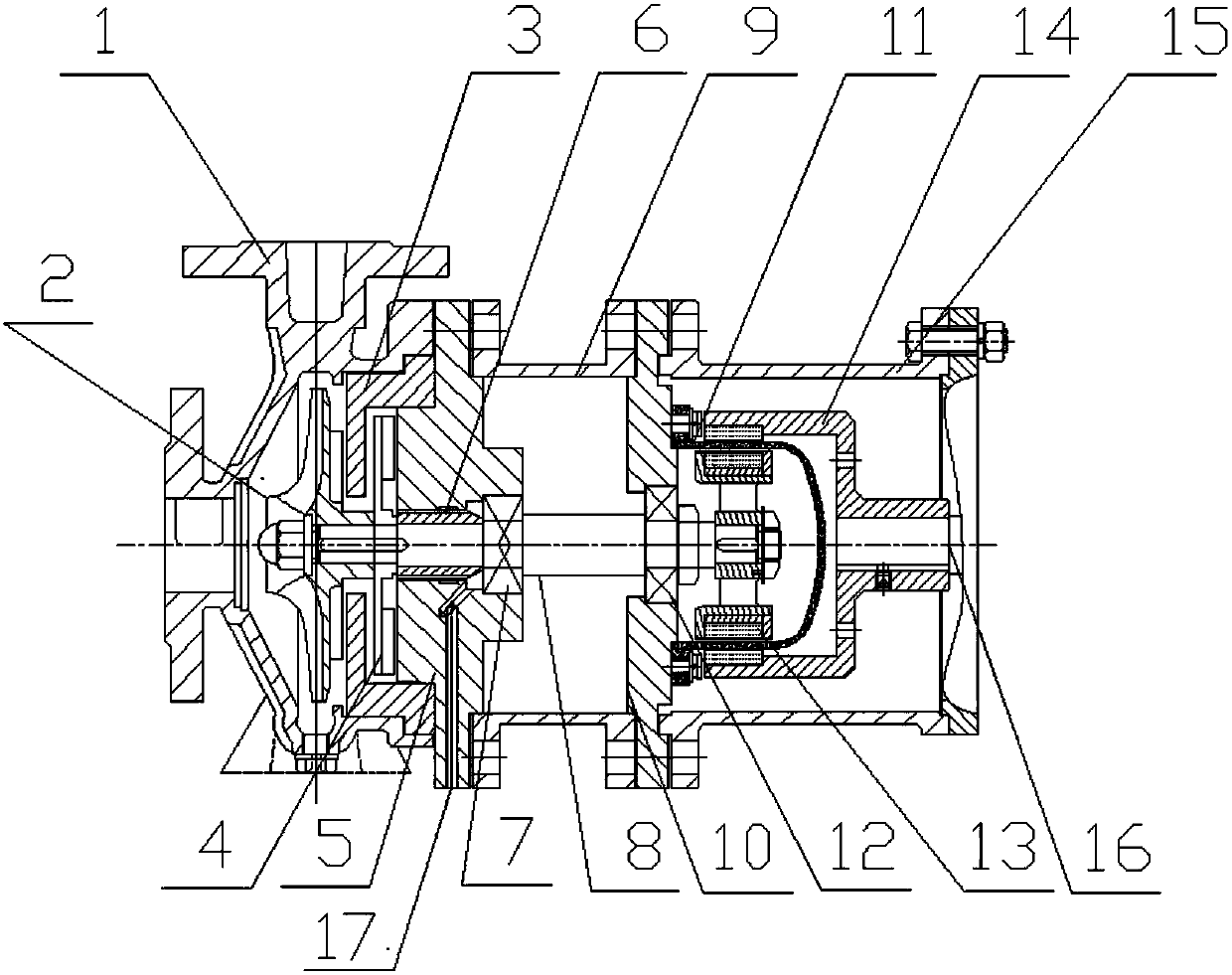

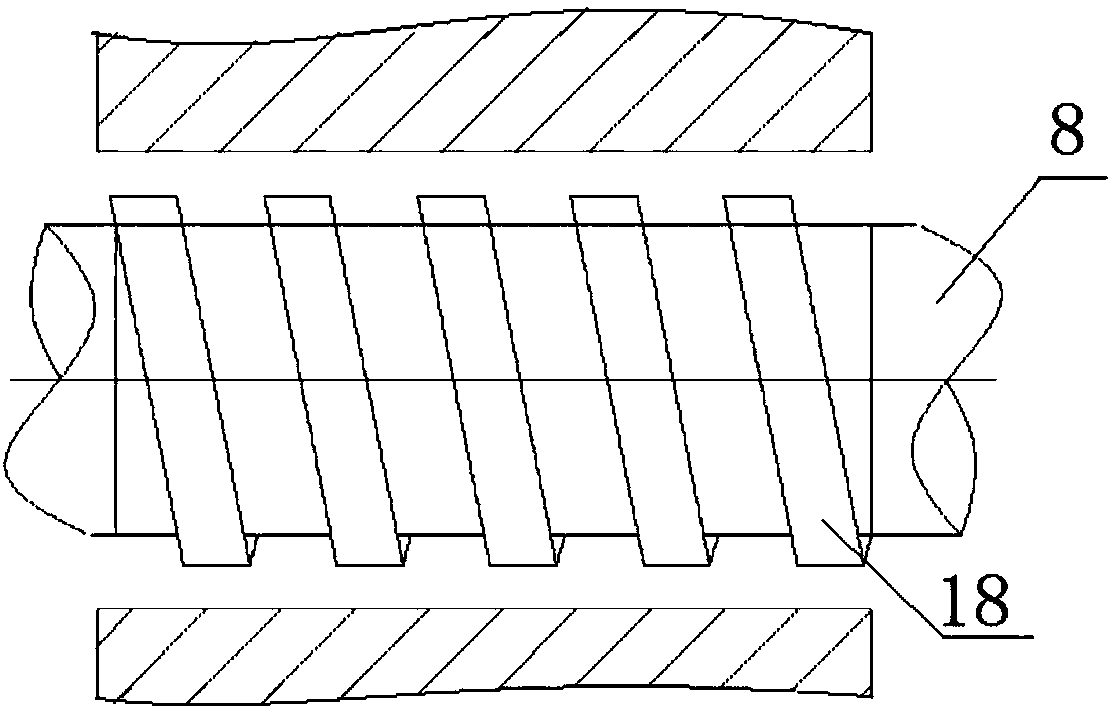

[0031] It is suitable for the secondary air source protection magnetic pump device for conveying the medium containing particle impurities, such as figure 1 As shown, it includes a water conservancy overcurrent unit, a magnetic drive unit and a secondary air source protection unit between them. The water conservancy overcurrent unit includes a pump body 1, an impeller 2, a pump cover 5 and a pump shaft 8. The pump body 1 and A pump cavity is formed between the pump covers 5, the impeller 2 is located in the pump cavity and connected to the pump shaft 8, the pump shaft 8 passes through the pump cover 5 and the secondary air source protection unit, and is connected with the magnetic drive unit, the impeller 2 and the pump The pump shaft 8 between the covers 5 is provided with an auxiliary impeller 4, and a front cover 3 is provided between the impeller 2 and the auxiliary impeller 4 (in this embodiment, the front cover 3 is fixed on the pump body 1 in the form of an annular cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com