Vibration Isolator and Damping Controllable Underwater Broadband Vibration Isolator

A vibration isolator and vibration isolation technology, applied in the direction of springs, etc., can solve the problems of reducing the stiffness of the vibration isolator, reducing the natural frequency of the system, and reducing the bearing capacity of the vibration isolator, so as to achieve the reduction of the natural frequency and the expansion of the vibration isolation frequency range The effect of widening and increasing the damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

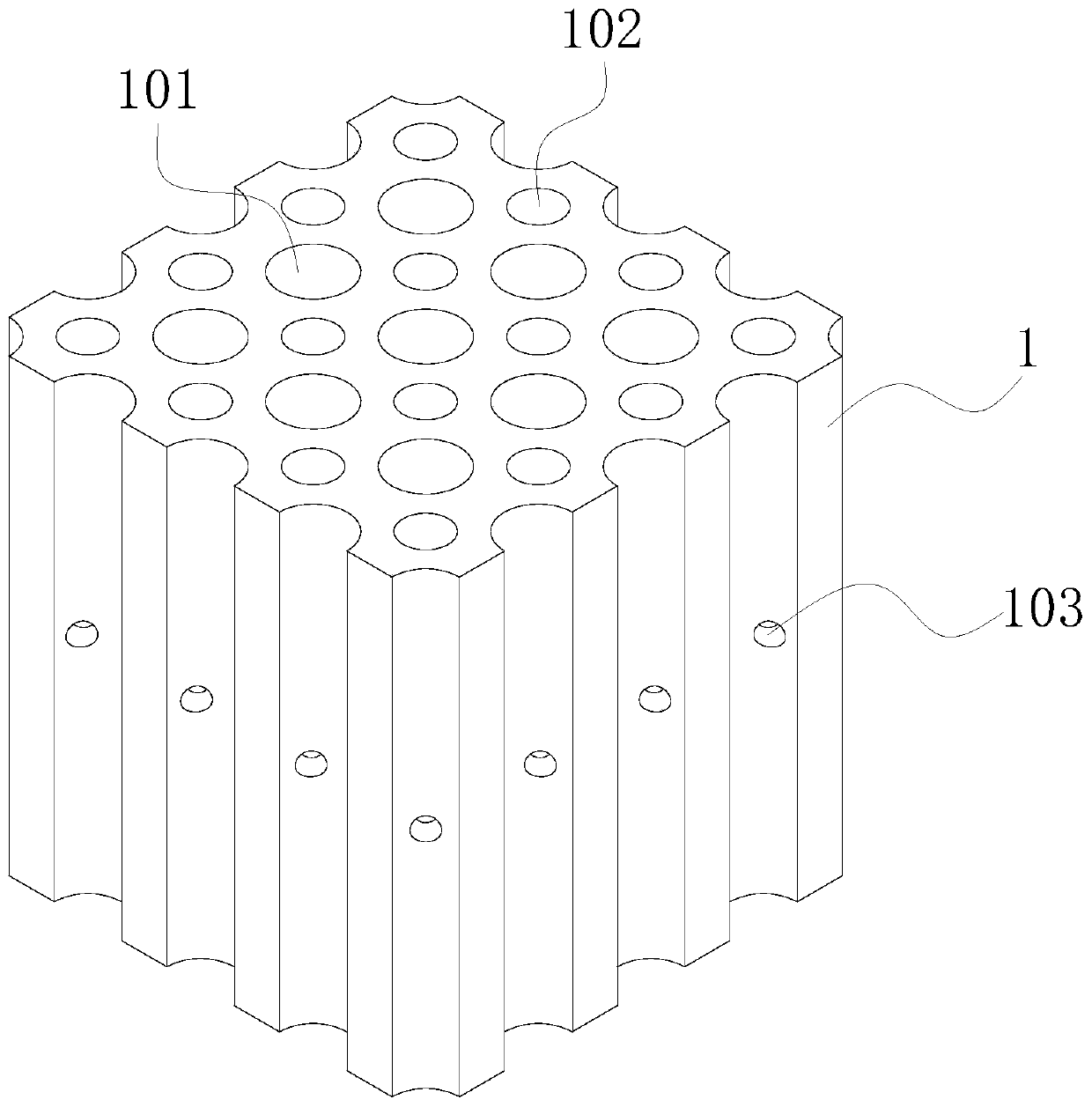

[0046] This embodiment discloses a vibration isolator, which mainly includes:

[0047] The vibration isolator base 1;

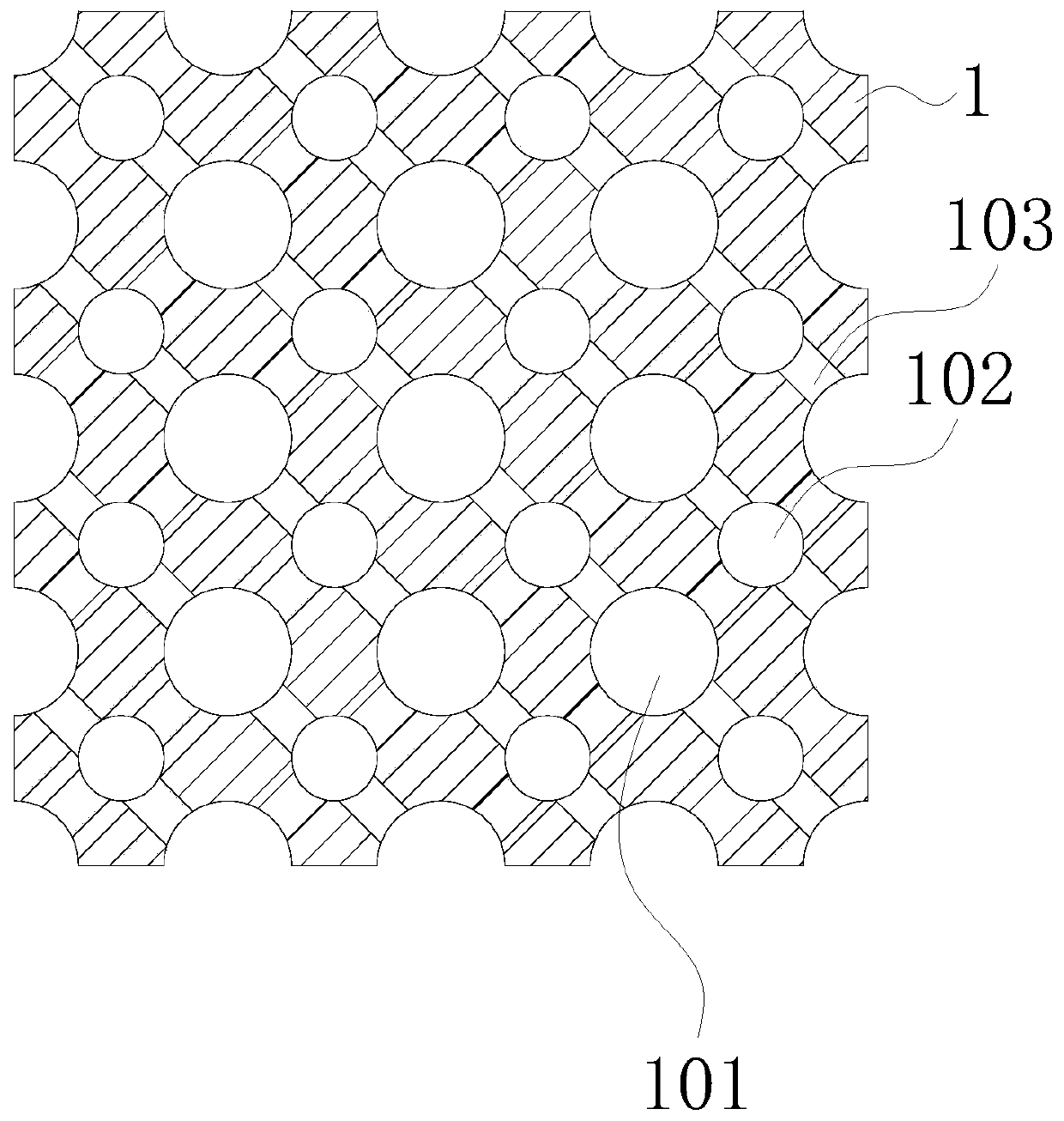

[0048] Stress dispersion holes 101 formed on the vibration isolator base 1; and

[0049] A fluid storage hole 102 formed on the base 1 of the vibration isolator;

[0050] Both the stress dispersion hole 101 and the fluid storage hole 102 are through holes opened on the base 1 of the vibration isolator, and the opening directions of the stress dispersion hole 101 and the fluid storage hole 102 are in the same direction;

[0051] A water guiding channel 103 is also formed on the base 1 of the vibration isolator;

[0052] The water guide passage 103 is configured as a structure communicating with the stress dispersion hole 101 and the fluid storage hole 102 .

[0053] Specifically, this embodiment discloses a vibration isolator. First, the vibration isolator has a base 1 of the vibration isolator as the main body, wherein the base 1 of the vibration isolator ...

Embodiment 2

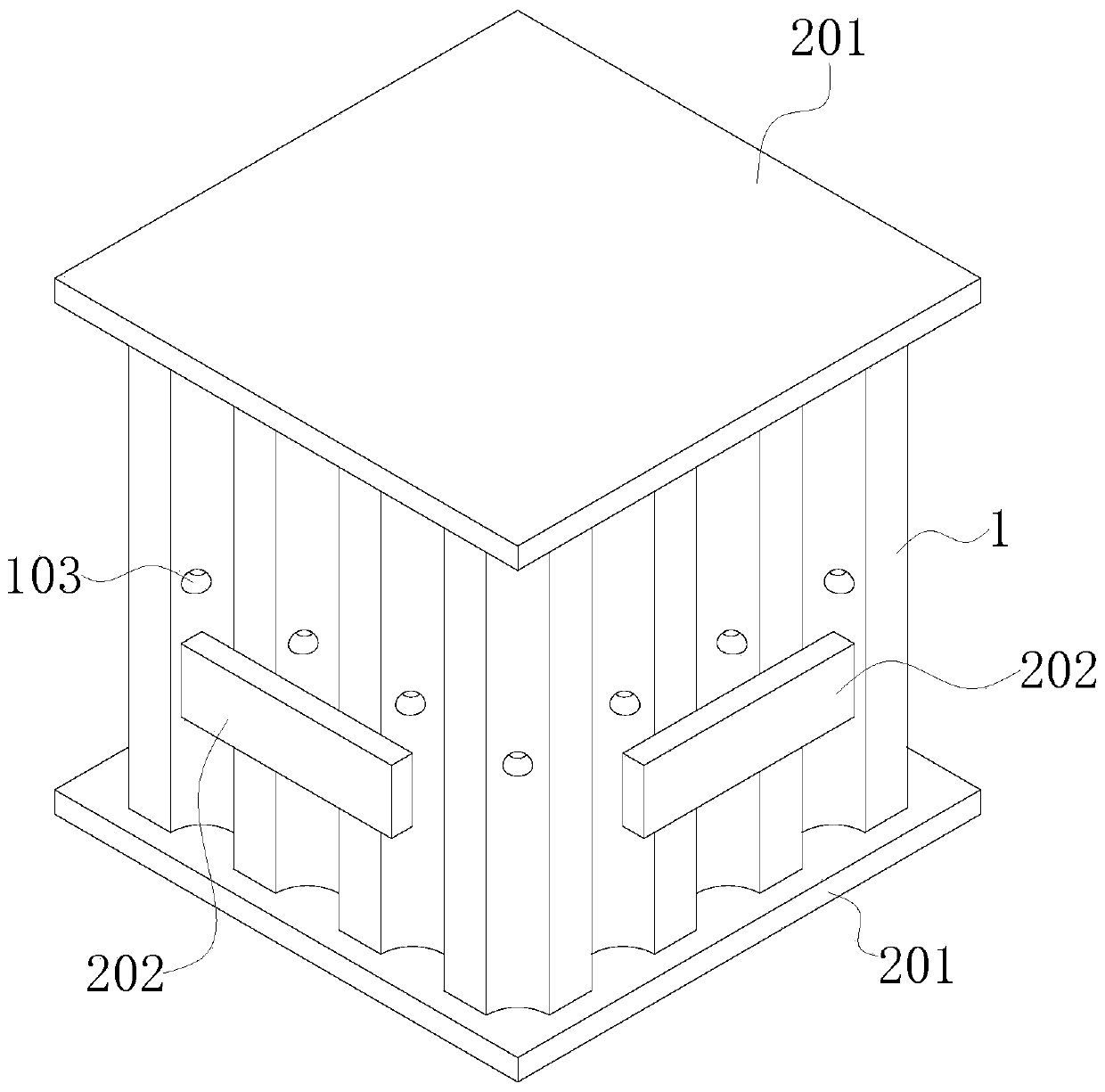

[0068] The invention discloses a damping controllable underwater broadband vibration isolator. The vibration isolator has the above-mentioned vibration isolator and a rigid component integrated on the vibration isolator. The vibration isolator is assembled with an external mechanism through the rigid component. .

[0069] First of all, based on the first embodiment above, the main structure of the vibration isolator and the principle of vibration and noise reduction are introduced. Among them, the second embodiment further discloses a vibration isolator with the above vibration isolator, which is mainly for water areas Environmental design, in order to be able to assemble with the external mechanism and play a certain supporting role for the external mechanism, in addition, to provide a certain rigidity for the vibration isolator to resist mechanical impact, the vibration isolator in this embodiment has a fixed connection on the vibration isolator rigid components.

[0070] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com