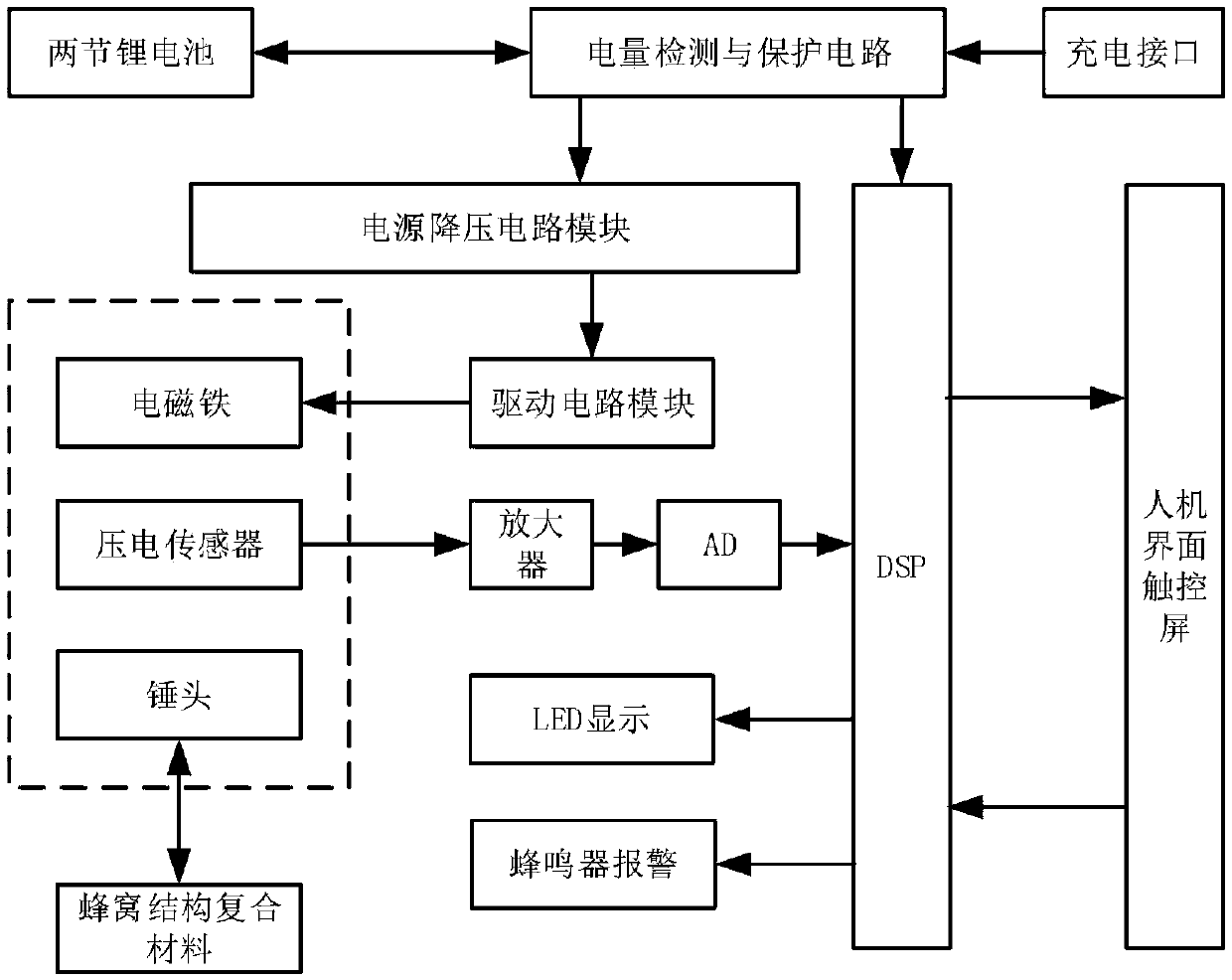

Handheld type knocking detector and detection method

A detector and hand-held technology, applied in the field of hand-held knock detectors, can solve the problems of inability to achieve multi-point layout, inability to detect weak signals, and occupying a larger system space, achieving multi-point layout and excellent pressure. Electric constant, the effect of improving detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

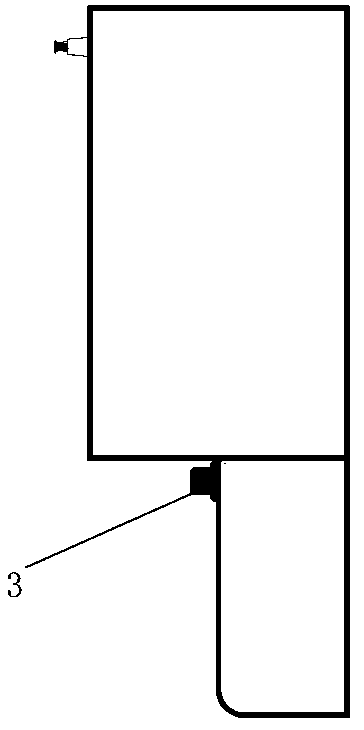

[0050] Step 1. Place the tested material on the test bench

[0051] Step 2. Turn on switch 3 to start the device;

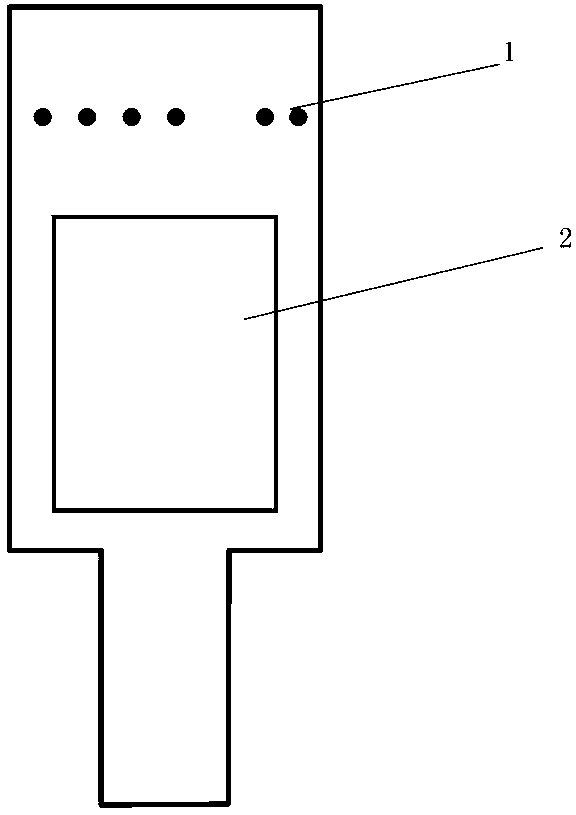

[0052] Step 3. Set parameters on the touch screen, input tapping speed 11, sampling average 12, working mode 13;

[0053] Step 4. Adjust the distance between the percussion hammer and the surface of the tested part to ensure that the distance between the percussion hammer and the surface of the tested part is within the distance of the percussion stroke

[0054] Step 5. Click to get reference on the touch screen, place the knock detector on the undamaged position of the tested part, and get the reference value.

[0055] Step 6: Start testing and observe the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com