Method for detecting residual expansion medium in cut tobacco

A shredded tobacco and medium technology, applied in the field of detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Weigh 0.5g (accurate to 0.001g) of the expanded cut tobacco sample in a 20mL headspace bottle, add 1mL cyclohexane, quickly press the bottle cap, put it into the headspace sampler of the automatic headspace instrument, and then put the The obtained headspace gas was measured by gas chromatography-mass spectrometry.

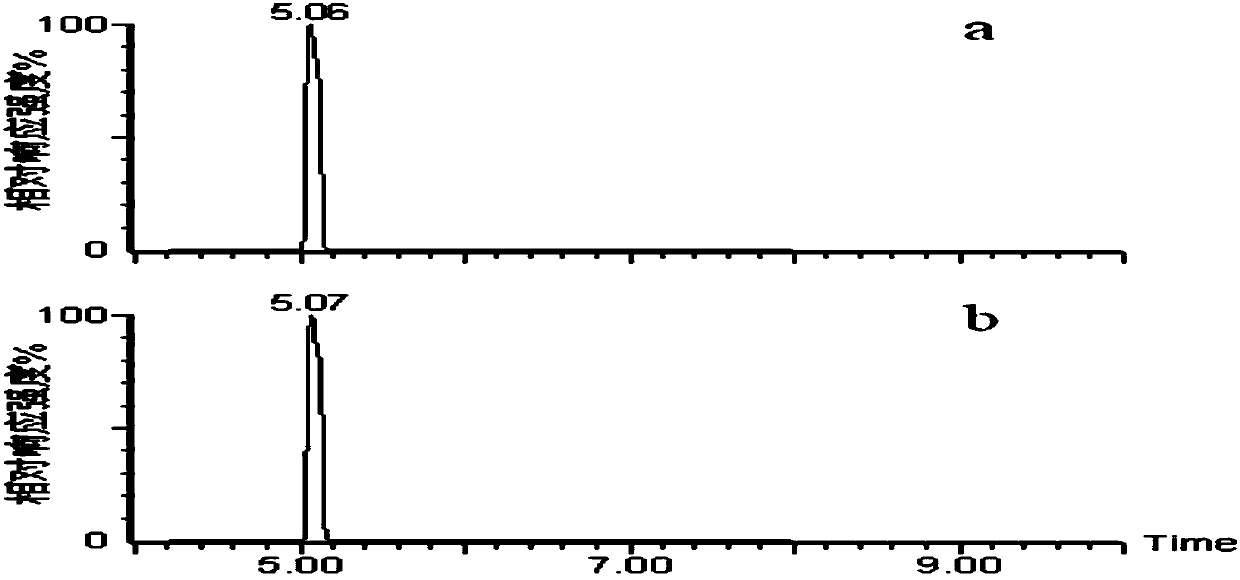

[0065] SHS-GC / MS (Static Headspace-Gas Chromatography-Mass Spectrometry) was used to conduct quantitative analysis and detection of the expansion medium KC-2A in shredded tobacco by external standard method, and the detection conditions were as follows:

[0066] Static headspace detection:

[0067] Sample equilibration temperature: 60°C; sample loop temperature: 120°C; transfer line temperature: 140°C; sample equilibration time: 15min; sample bottle pressurization pressure: 35psi; carrier gas pressure: 40psi; 0.20min; sample loop equilibration time: 0.05min; injection time: 0.1min.

[0068] Gas chromatography detection:

[0069] Chromatographic column: H...

Embodiment 2

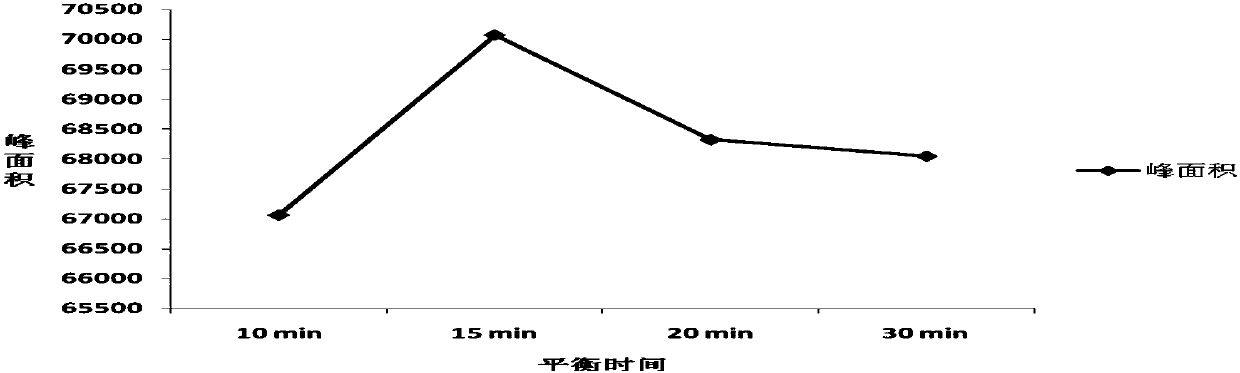

[0075] The 70 μg / mL KC-2A medium standard solution was added to the unexpanded shredded tobacco, and the equilibration temperature was 60°C, and the equilibration time was measured for 10min, 15min, 20min and 30min respectively, and other detection conditions were the same as in Example 1. Measurement results such as figure 1 shown. Depend on figure 1 It can be seen that the medium KC-2A response chromatogram peak area equilibrium time increased slightly from 10min to 15min, decreased slightly between 15min and 20min, and basically had no difference between 20min and 30min. Since the medium KC-2A has a low boiling point and is volatile, the relative equilibration time has little influence. In order to fully equilibrate the sample to be tested, 15min is the best equilibration time.

Embodiment 3

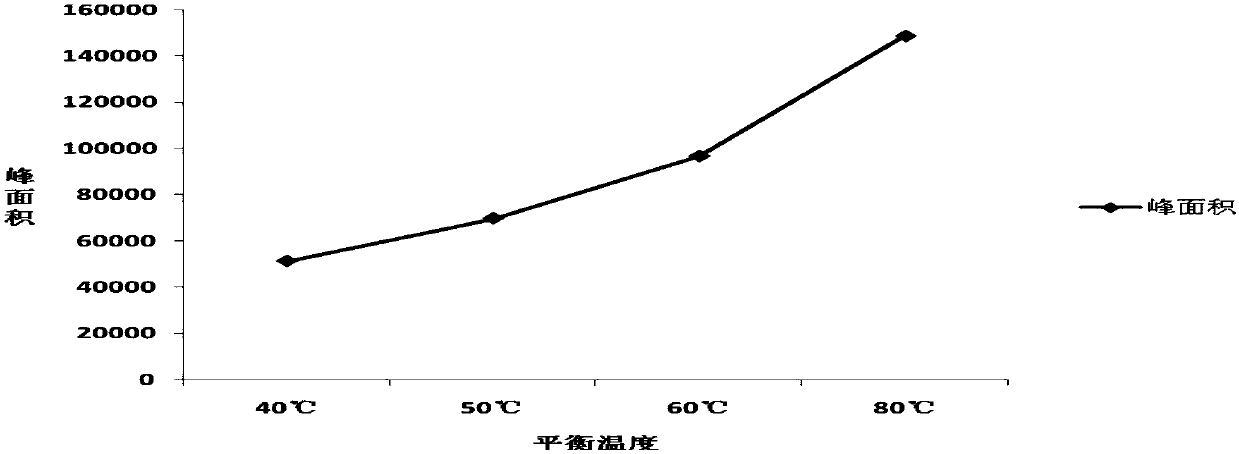

[0077] Add 70 μg / mL of KC-2A medium standard solution to unexpanded shredded tobacco, and measure at equilibrium temperatures of 40°C, 50°C, 60°C, and 80°C at an equilibrium time of 15 minutes, and other detection conditions are the same as in the examples 1. Test results such as figure 2 shown by figure 2 It can be seen that with the increase of equilibrium temperature, the peak area of KC-2A medium increases gradually, and the growth rate is slightly smaller at 40-60 °C, but the growth rate is obvious at 60-80 °C. Usually, the expansion medium KC-2A in expanded tobacco shreds is detected at room temperature. 2A residue, and the medium KC-2A has a low boiling point, taking into account the full volatilization of the sample medium KC-2A, as well as the requirements of improving the sensitivity of the method and reducing the interference of the sample matrix, the best equilibrium temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com