Earth-continuity tester calibration system

A resistance tester and grounding conduction technology, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, etc., can solve the problems of wrong measurement values and poor stability of resistance values, and achieve the effects of strong versatility, high precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

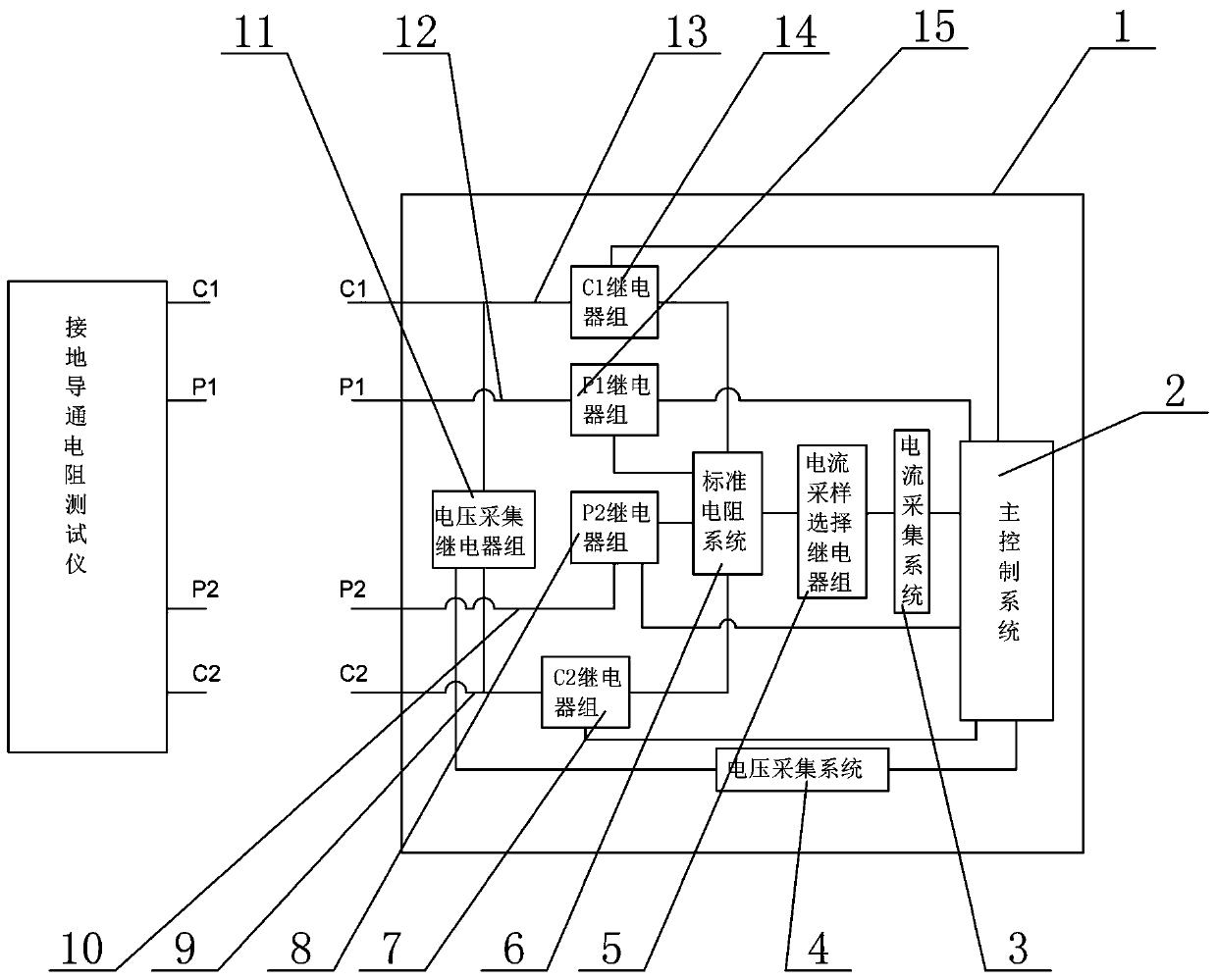

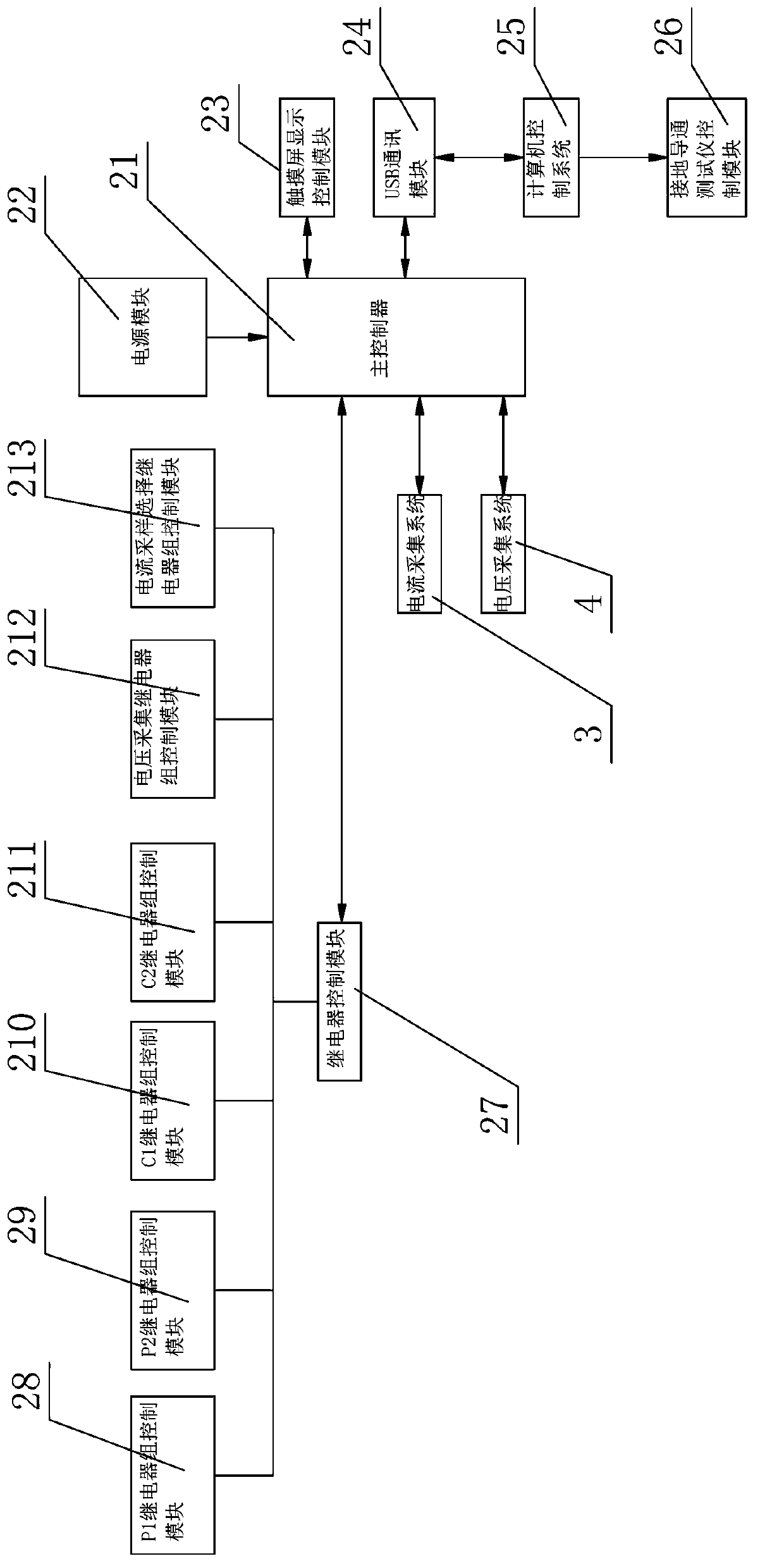

[0045] Such as figure 1 As shown, a calibration system for a ground bond resistance tester includes a housing 1, four terminals and a standard resistance system 6 arranged in the housing 1, a current acquisition system 3, a voltage acquisition system 4, a C1 relay group 14, and a C2 Relay group 7, P1 relay group 15, P2 relay group 8, voltage acquisition relay group 11, current sampling selection relay group 5 and main control system 2, the shell 1 is provided with four terminals, which are respectively C1 terminals , C2 terminal, P1 terminal and P2 terminal, the standard resistance system 6 is electrically connected to the C1 bus 13 through the C1 relay group 14, the C1 bus 13 is connected to the C1 terminal on the shell 1, and the standard resistance system 6 is connected to the C2 relay group 7 Electrically connected with C2 bus 9, C2 bus 9 is connected with C2 terminal on shell 1, standard resistance system 6 is electrically connected with P1 bus 12 through P1 relay group 1...

Embodiment 2

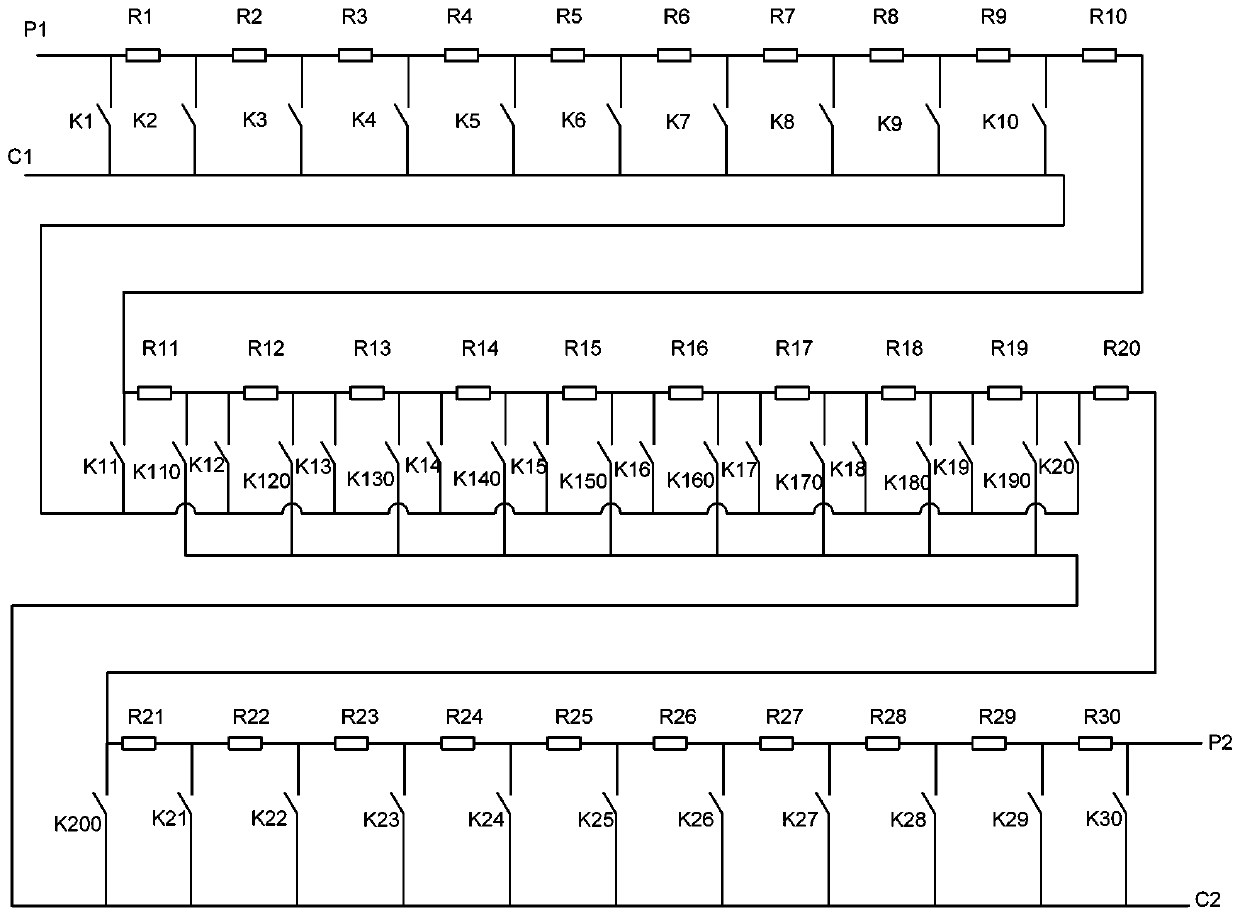

[0076] Such as Figure 12 As shown, repeating Example 1, there are the following differences: the standard resistor system 6 includes ten 1mΩ standard resistors, ten 10mΩ standard resistors and ten 100mΩ standard resistors, and each standard resistor includes four connection terminals, which are respectively current terminals C1, current terminal C2, potential terminal P1 and potential terminal P2, the potential terminals of all standard resistors are connected in series, and the current terminals of all standard resistors are connected in series to form a standard resistor row, and the potential terminals at both ends of the standard resistor row are respectively connected in series with a relay After that, they are respectively connected to the P1 terminal and the P2 terminal on the shell 1, the current terminal C1 of each standard resistor is connected to a relay and then connected to the C1 bus 13, and the current terminal C2 of each standard resistor is connected to a rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com