Arc extinguishing slurry and its preparation method and application

A technology of arc extinguishing and slurry, applied in emergency protection devices, electrical components, circuits, etc., can solve the problems of low temperature curing, poor arc extinguishing performance, high viscosity, etc., and achieve low production cost, easy operation, and easy molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

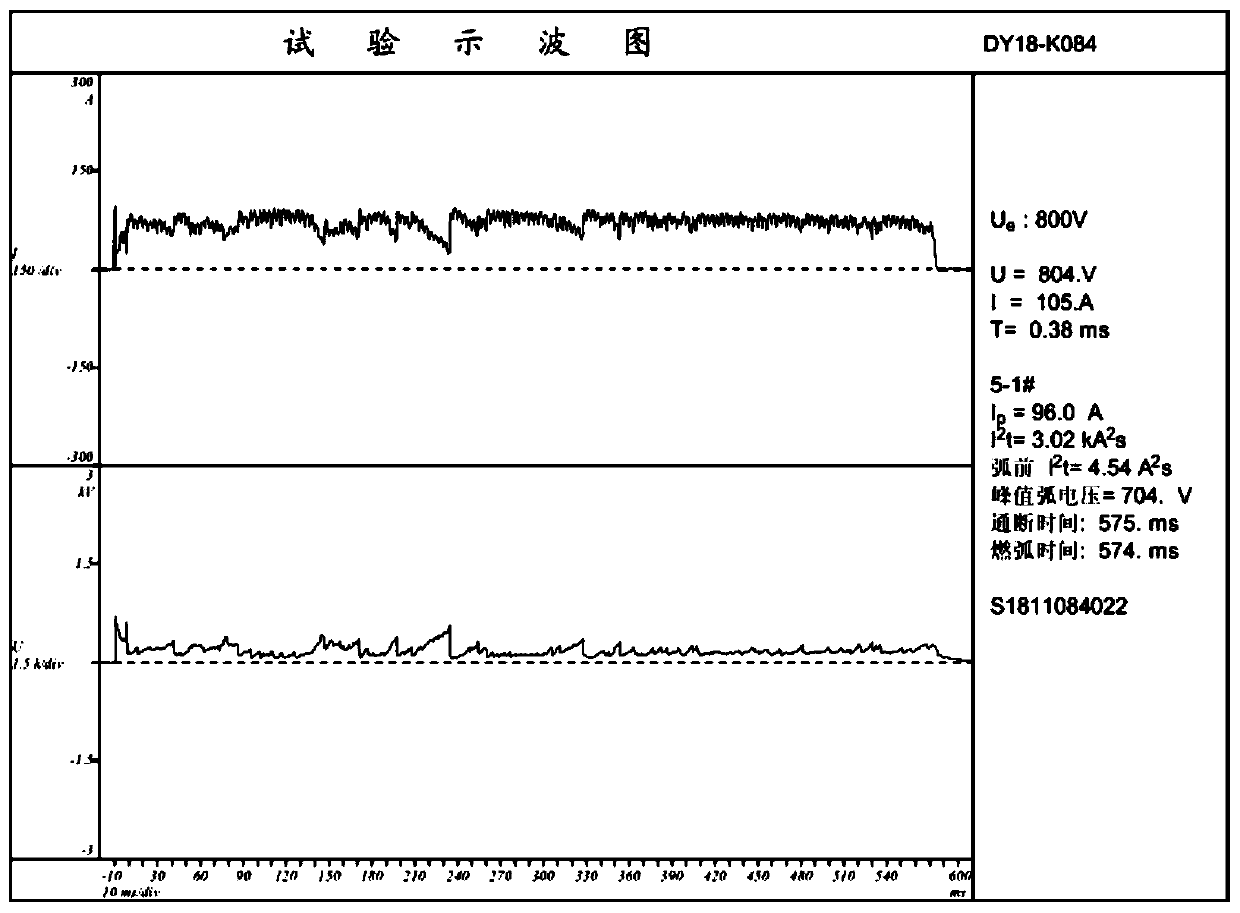

Image

Examples

Embodiment 1

[0032] According to the calculation, weigh 76g of quartz sand, 24g of deionized water, 2.28 g of monomer N,N-dimethylacrylamide (accounting for 3% of the mass of quartz sand), M 单体 :M 交联剂 =10:1 (mass ratio), the crosslinking agent is N, N-methylenebisacrylamide, the addition amount of the dispersant polyethyleneimine is 0.114g (accounting for 0.15% of the mass of the quartz sand) and 152g of zirconia balls , and added to the ball mill tank in sequence according to the weighing order, set the speed of the ball mill to 220r / min, and after 4 hours of ball milling, a low-temperature solidified slurry with a slurry viscosity of 0.02Pa.s was obtained.

[0033] Assemble a 95 alumina ceramic tube with a size of 15.4×4.56×4.56, a copper cap, and a fuse on the assembly table to form a semi-finished fuse with one end copper cap welded and the other end copper cap unwelded, and then the prepared arc extinguishing The slurry is injected and filled into the alumina ceramic tube, and then t...

Embodiment 2

[0036] According to the calculation, weigh 80g of quartz sand, 20g of deionized water, 1.6 (accounting for 2% of the mass of quartz sand) g of N,N-dimethylacrylamide, M 单体 :M 交联剂 =6:1 (mass ratio), the crosslinking agent is N,N-methylenebisacrylamide, the addition amount of the dispersant polyethyleneimine is 0.08g (accounting for 0.1% of the mass of the quartz sand) and 160g of zirconia balls , according to the order of weighing into the ball mill tank, set the speed of the ball mill to 220r / min, after 4 hours of ball milling, a low-temperature solidified slurry with a slurry viscosity of 0.5Pa.s was obtained.

[0037] Assemble a 95 alumina ceramic tube with a size of 15.4×4.56×4.56, a copper cap, and a fuse on the assembly table to form a semi-finished fuse with one end copper cap welded and the other end copper cap unwelded, and then the prepared arc extinguishing The slurry is injected and filled into the alumina ceramic tube, and then the other end of the ceramic tube is...

Embodiment 3

[0040] According to the calculation, weigh 85g of quartz sand, 15g of deionized water, 4.25g of monomer N,N-dimethylacrylamide (accounting for 5% of the mass of quartz sand), M 单体 :M 交联剂=12:1 (mass ratio), the crosslinking agent is N, N-methylenebisacrylamide, the amount of dispersant added is 0.425g (accounting for 0.5% of the mass of quartz sand) and 170g of zirconia balls, weighed Sequentially add to the ball mill tank, set the speed of the ball mill to 220r / min, after 4 hours of ball milling, the slurry viscosity is 3Pa.s low-temperature solidified slurry. The solid content of the slurry is relatively high, resulting in a high viscosity of the slurry, which makes it difficult for the slurry to be poured into the ceramic tube.

[0041] Assemble a 95 alumina ceramic tube with a size of 15.4×4.56×4.56, a copper cap, and a fuse on the assembly table to form a semi-finished fuse with one end copper cap welded and the other end copper cap unwelded, and then the prepared arc ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com