Repair method of tunnel secondary lining concrete exposed reinforcement

A secondary lining and repair method technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., to achieve the effect of increasing tensile and impermeable strength, solving anti-corrosion, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for repairing exposed reinforcement of concrete in a secondary lining of a tunnel, comprising the following steps:

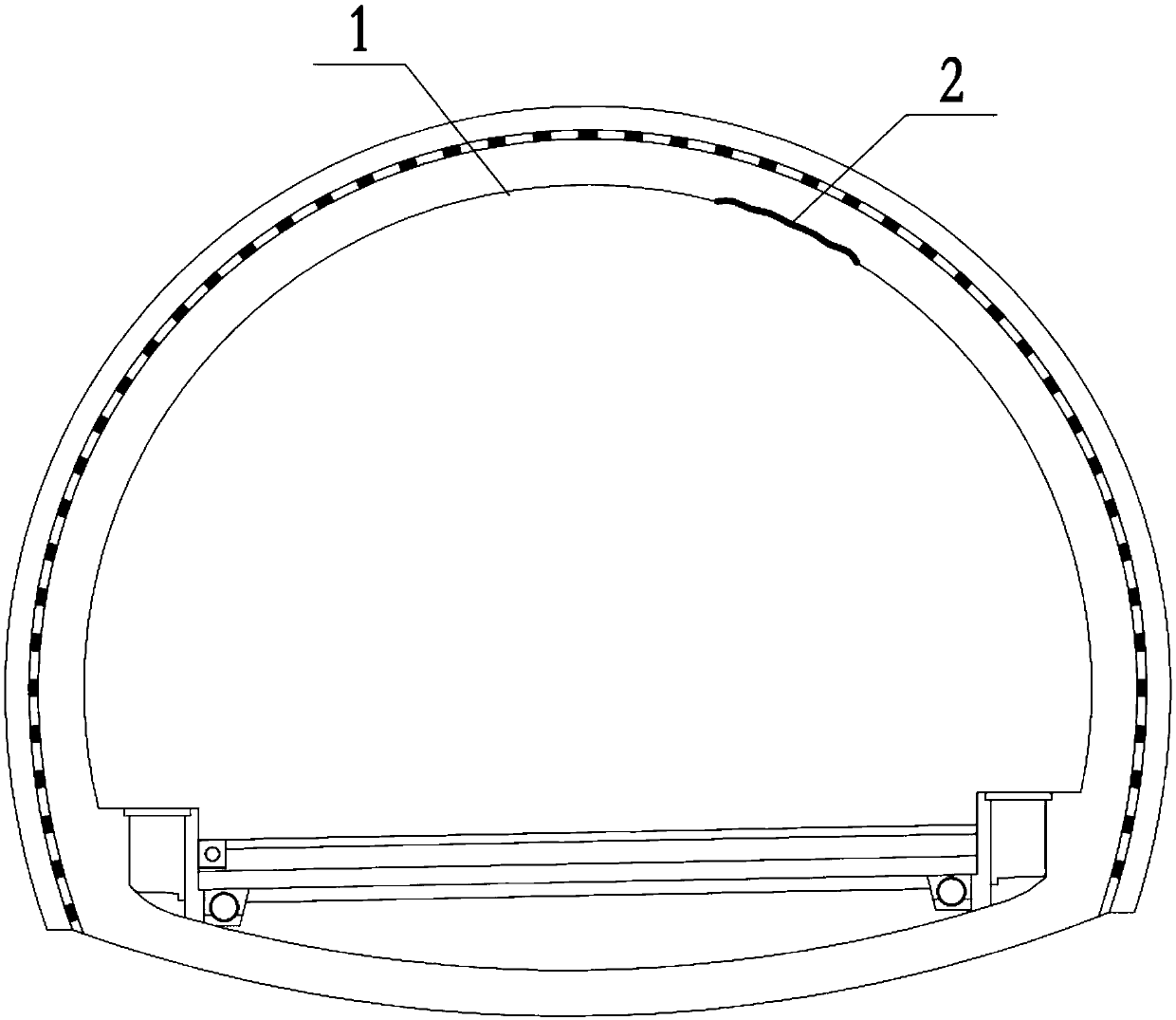

[0028] a. Determine the insufficient protective layer of the steel bar or the location of the exposed bar damage, and use the corrosion potential measuring instrument to detect the corrosion of the steel bar in the tunnel. Different corrosion levels will produce different corrosion potentials, which will cause changes in the full battery potential. Evaluate the corrosion state by the electric potential of the point, and evaluate its corrosion activity according to the evaluation standard, and mark the contour line of the inner arch surface of the secondary lining 1 where the steel reinforcement protective layer is insufficient or the exposed reinforcement diseased part needs to be repaired, and the treatment area 2 is obtained;

[0029] b. Use a high-pressure air gun to clean the surface of the treatment area;

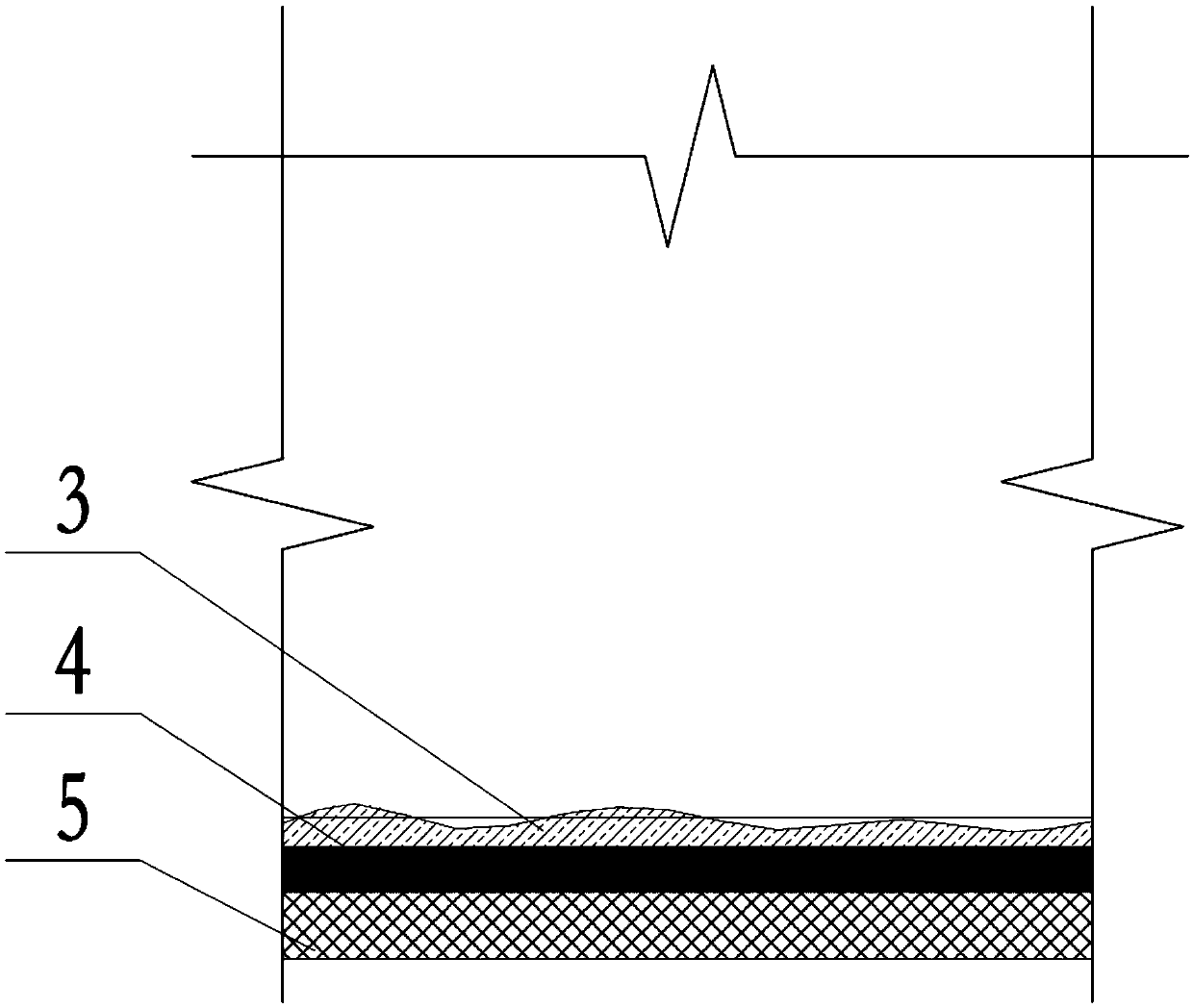

[0030] c. Apply a layer of water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com