Solving method of electromagnetic design used for surface-mounted permanent magnet motor

A technology of permanent magnet motor and electromagnetic design, applied in electromechanical devices, manufacturing of motor generators, design optimization/simulation, etc., can solve problems such as long solution time, inability to directly correspond between performance and motor size parameters, and increased errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

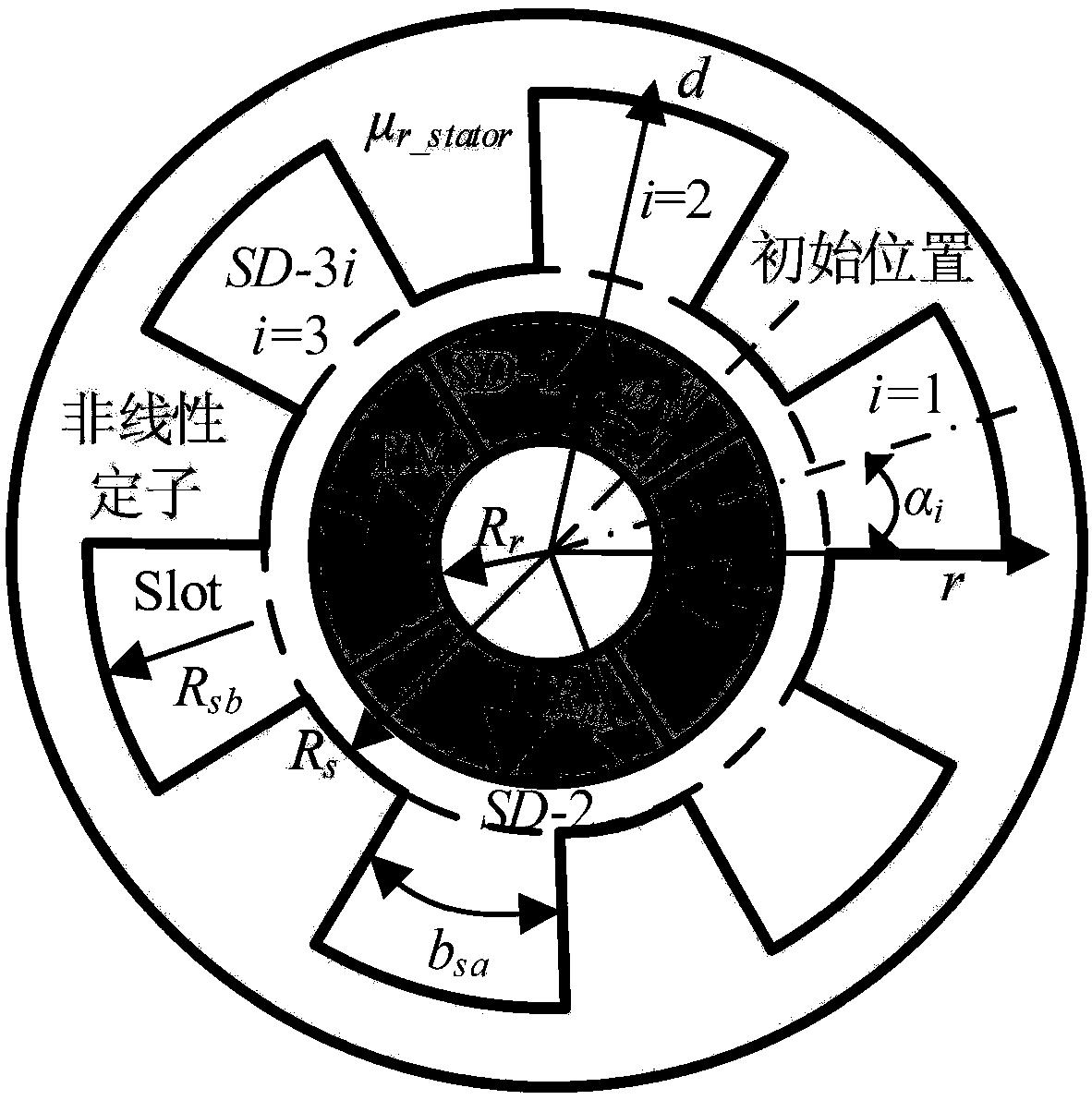

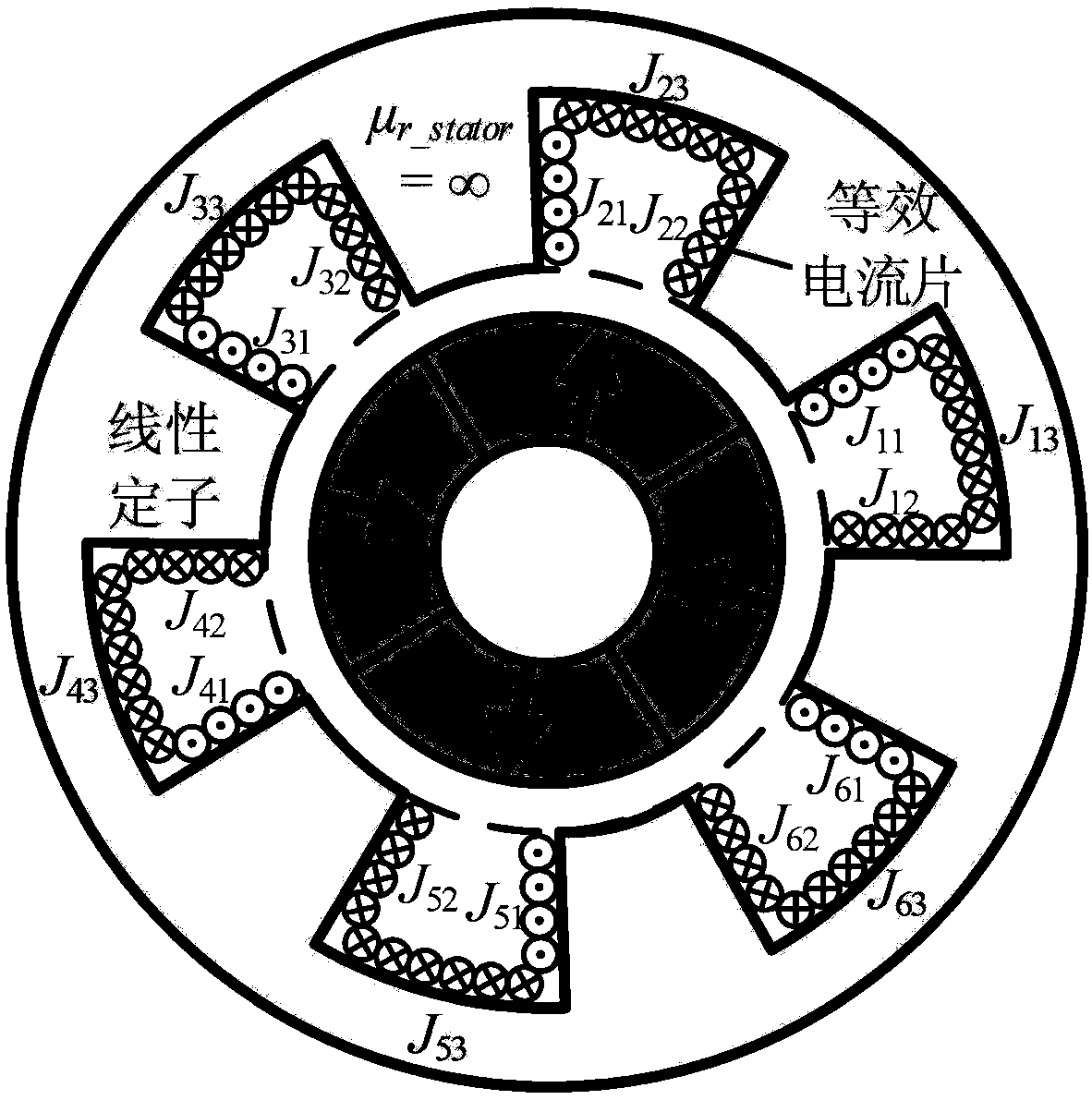

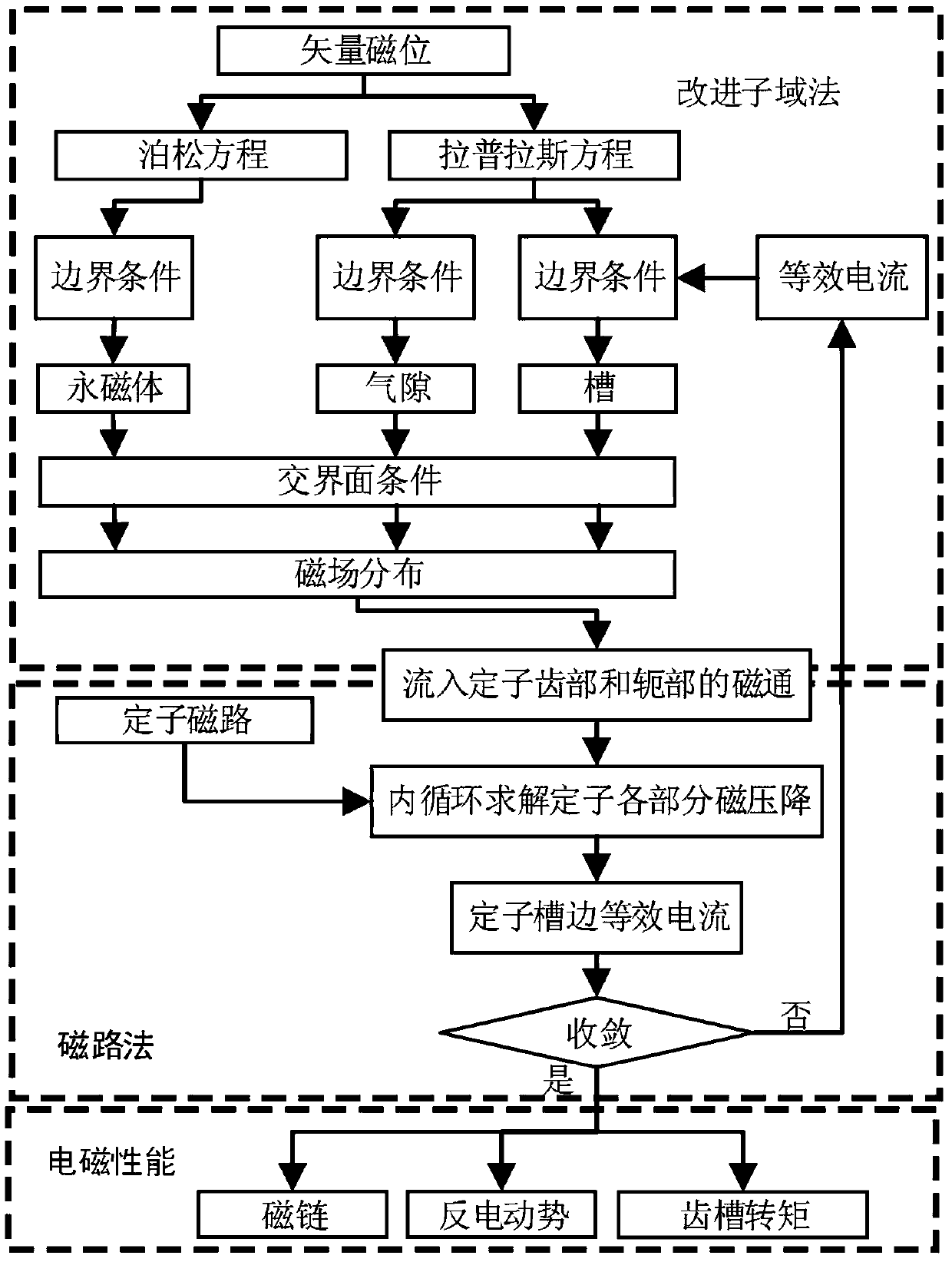

[0102] In the present invention, it is mainly used in the electromagnetic design of the surface-mounted permanent magnet motor, and its model is as follows figure 1 As shown, the figure shows a surface-mounted permanent magnet motor with 4 poles and 6 slots. The stator is made of nonlinear silicon steel. SD-1, SD-2 and SD-3 are permanent magnets, air gaps and stator slots respectively. subfields, ω r is the rotational angular velocity of the rotor, α i is the angle of the i-th groove centerline, r and α are the radial and tangential positions in the polar coordinate system, b sa is the notch width, R r , R m , R s and R sb are the radii from the rotor yoke, permanent magnet surface, slot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com