Easily controllable multi-stage series gas generator and chlorine dioxide generator

A gas generating device and chlorine dioxide technology, applied in the direction of chlorine dioxide, chlorine dioxide, etc., can solve the problems that the reaction speed cannot be kept constant, the reaction speed of chlorine dioxide generator is difficult to control, and is difficult to control, so as to achieve convenient Control speed, high degree of automation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

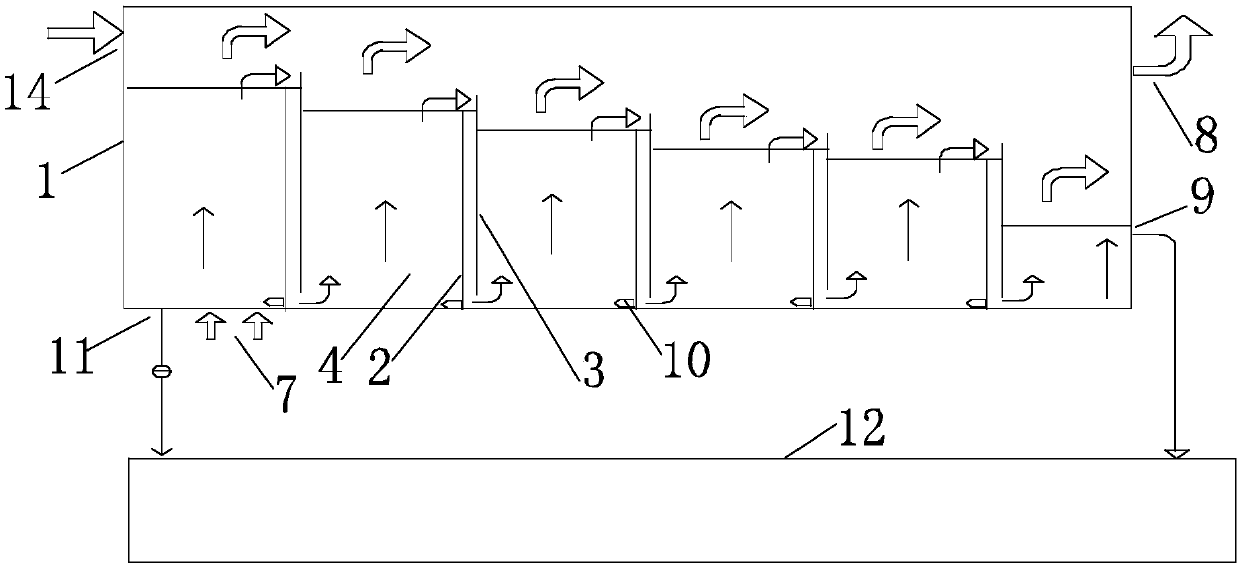

[0087] Embodiment one: carry out as Image 6 The structure diagram shown examines the evolution of chlorine dioxide generation over time.

[0088] A bottle: hold 1000ml of clean water to remove oxides in the air, if nitrogen is used, there is no need to use a clean water bottle.

[0089] B bottle: a is the air inlet, b is the chlorine dioxide gas outlet.

[0090] Operation: After connecting the AB bottle as shown in the figure, turn on the fan and blow it for ten minutes. If the color of the solution does not change, the solution may not be taken), add it to the iodine measuring bottle and perform titration according to the requirements of the five-step iodometric method, and calculate the amount of chlorine dioxide generated according to the relevant formula. The experimental results are as follows:

[0091] The change of chlorine dioxide gas production (mg / h) in three days is shown in the table below:

[0092] Sampling period (days)

[0093] The preset value of...

Embodiment 2

[0097] Embodiment two, operate according to the method of embodiment one, the result is as follows.

[0098] The change of chlorine dioxide gas production (mg / h) in three days is shown in the table below:

[0099]

[0100]

[0101] The preset value of chlorine dioxide gas generation is 190mg / h. From the above table, it can be seen that the stable operation starts from the 7th day.

[0102] The change of chlorine dioxide gas generation (mg / h) when the liquid addition period is four days is shown in the table below:

[0103] Sampling period (days)

[0104] The preset value of chlorine dioxide gas generation is 150mg / h. From the above table, it can be seen that the stable operation starts from the 6th day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com