Preparation method of high anti-elastic aluminum alloy plate

An aluminum alloy plate, anti-ballistic technology, applied in the field of preparation of high anti-elastic aluminum alloy plate, can solve the problems of stress corrosion cracking sensitivity, etc., achieve the effect of improving mechanical properties, excellent stress corrosion resistance, and improving battlefield survivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In some illustrative embodiments, embodiment 1: a method for preparing a high anti-ballistic aluminum alloy plate, comprising the following steps:

[0036] S1: The aluminum alloy ingot is made into an aluminum alloy plate by extrusion; the aluminum alloy ingot is an aluminum alloy ingot produced by conventional high-temperature melting of raw materials and then using a conventional casting process.

[0037] The specific steps are:

[0038] S101: heating the aluminum alloy ingot with a diameter of 500mm to 440-450°C and keeping it warm for 10-12h;

[0039] S102: The preheating temperature of the extrusion die is 400-420°C, and the preheating temperature of the extrusion barrel is 420-430°C;

[0040] S103: placing the aluminum alloy ingot in the extrusion cylinder for extrusion at an extrusion speed of 0.2-0.3mm / s;

[0041] S103: extruding to obtain an aluminum alloy plate with a final extruded size of 30mm*710mm;

[0042] S2: heat-treating the aluminum alloy plate obt...

Embodiment 2

[0055]Embodiment 2:, by mass percentage, the chemical composition of the aluminum alloy ingot is as follows: Zn: 8.2%, Cu: 2.0%, Mg: 2.0%, Zr: 0.15%, CeO2: 0.1%, Fe≤0.10 %, Cr+Ti≤0.07%, and the balance is Al. The preparation method is the same as in Example 1.

Embodiment 3

[0056] Embodiment 3: Calculated by mass percentage, the chemical composition of the aluminum alloy ingot is as follows: Zn: 8.8%, Cu: 2.5%, Mg: 2.6%, Zr: 0.30%, CeO2: 0.3%, Fe≤0.10% , Cr+Ti≤0.07%, and the balance is Al. The preparation method is the same as in Example 1.

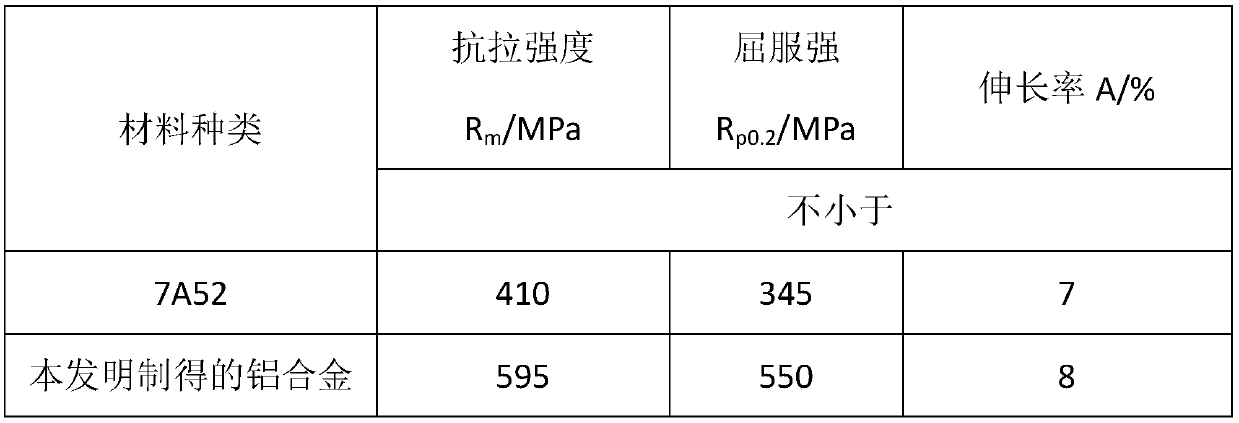

[0057] The finished product prepared by embodiment 1 is compared with existing 7A52 aluminum alloy for performance test:

[0058] The comparison of mechanical properties is shown in the table below:

[0059]

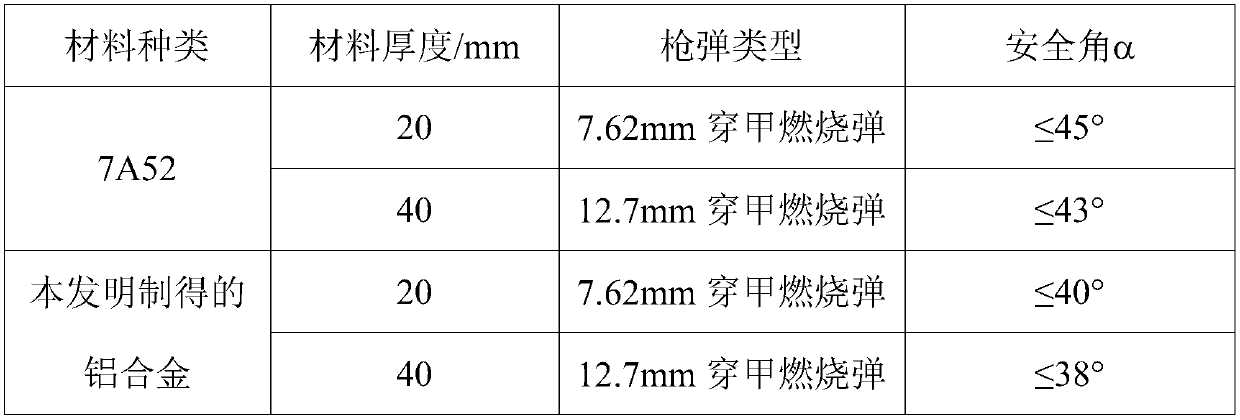

[0060] Ballistic performance comparison parts in the following table:

[0061]

[0062] Comparing 7A52 and the aluminum alloy prepared by the present invention, it can be found that the tensile strength of the aluminum alloy obtained by the present invention is 29.6% higher than that of the existing 7A52 aluminum alloy armor material, and the elongation is equivalent to that of the 7A52 aluminum alloy. The mechanical properties are obviously better than the existing aluminum alloy armor materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com