A kind of garment-dyed wool worsted tweed fabric and its production method

A technology for garment dyeing and production methods, applied in dyeing, weaving, and patterned fabrics, etc., can solve the problems of not being able to directly form the pattern pattern of deep and shallow interweaving changes, and being unable to meet the needs of high-grade woolen fabrics, and to achieve good market promotion. Application value, rich and diverse colors, the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

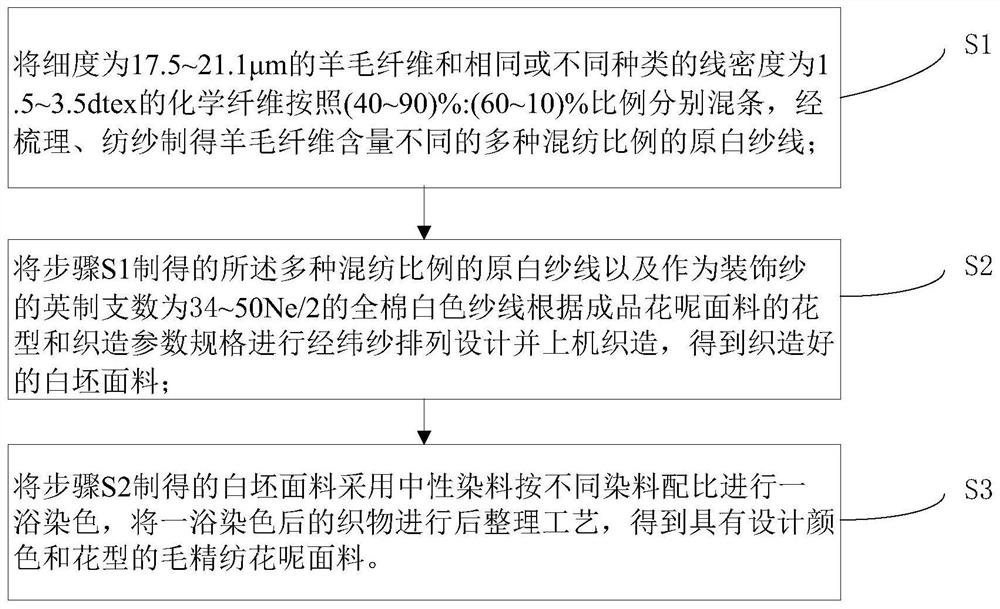

[0049] as attached figure 1 Shown, a kind of production method of garment-dyed wool worsted tweed fabric comprises the following steps:

[0050] S1. Mix the wool fiber with a fineness of 19.4 μm and the nylon fiber with a linear density of 3.2dtex according to the ratio of 80%: 20%. After carding and spinning, a wool fiber and nylon blended metric count is obtained. 60Nm / 2 raw white yarn; wool fiber with a fineness of 19.4μm and polyester fiber with a linear density of 2.5dtex are mixed according to the ratio of 40%:60%, carded and spun to obtain another wool fiber Raw white yarn of metric count 60Nm / 2 blended with polyester.

[0051] The production method of described former white yarn comprises the following steps:

[0052] S11. Defelt and mix the original white wool strips;

[0053] S12. Combing, needle combing, and roving. Combing adopts the processing technology of dense needles, small gauge, low speed, small feeding, and small draft. Head needle—combing—head needle—tw...

Embodiment 2

[0074] as attached figure 1 Shown, a kind of production method of garment-dyed wool worsted tweed fabric comprises the following steps:

[0075] S1. Mix the wool fiber with a fineness of 18.5 μm and the nylon fiber with a linear density of 3.0 dtex according to the ratio of 40%:60% and 80%:20%, respectively, and after carding and spinning, two blends with different ratios are obtained. Wool fiber and nylon blended raw white yarn with a metric count of 80Nm / 2; wool fiber with a fineness of 18.5μm and polyester fiber with a linear density of 2.0dtex according to the ratio of 70%: 30%, after carding , spinning, the metric system count that makes a kind of wool fiber and terylene blending is the former white yarn of 80Nm / 2.

[0076] The production method of described former white yarn comprises the following steps:

[0077] S11. Defelt and mix the original white wool strips;

[0078] S12. Combing, needle combing, and roving. Combing adopts the processing technology of dense nee...

Embodiment 3

[0099] as attached figure 1 Shown, a kind of production method of garment-dyed wool worsted tweed fabric comprises the following steps:

[0100]S1. Mix the wool fiber with a fineness of 17.5 μm and the nylon fiber with a linear density of 3.4 dtex according to the ratio of 70%:30% and 50%:50%, respectively, and after carding and spinning, two different ratios are obtained. The original white yarn with a metric count of 90Nm / 2 of wool fiber and nylon blended; the wool fiber with a fineness of 17.5μm and the polyester fiber with a linear density of 1.5dtex are respectively 60%: 40%, 90%: 10% Ratio mixed sliver, through carding, spinning, make the original white yarn of 90Nm / 2 the metric system count of other two kinds of different proportions of wool fiber and polyester blend.

[0101] The production method of described former white yarn comprises the following steps:

[0102] S11. Defelt and mix the original white wool strips;

[0103] S12. Combing, needle combing, and rovin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com