Yarn and fabric with electrostatic load characteristics

A technology of load characteristics and yarns, applied in the field of textile fabrics, can solve the problems of brittleness and easy shedding of coatings, limited electrostatic load capacity, and limited research on electrostatic load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

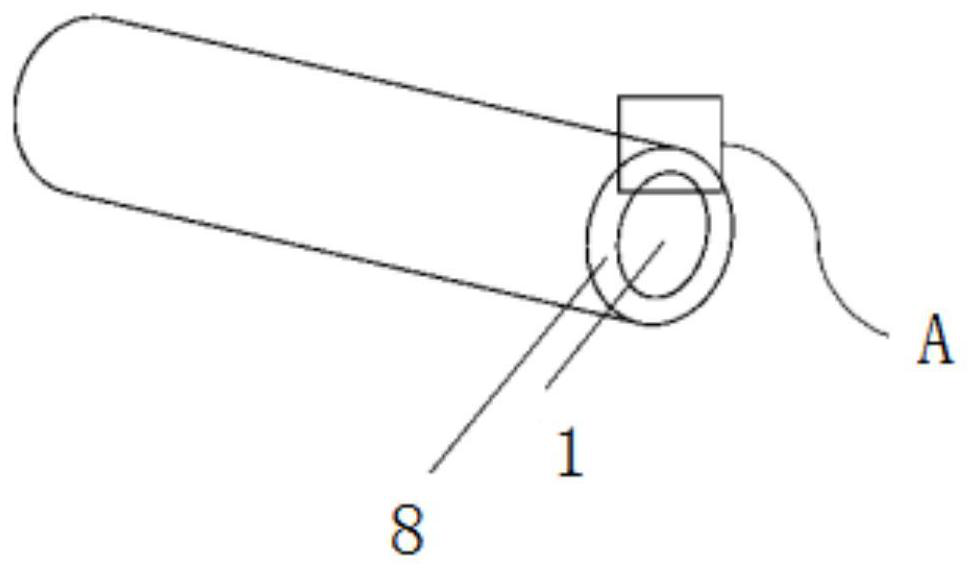

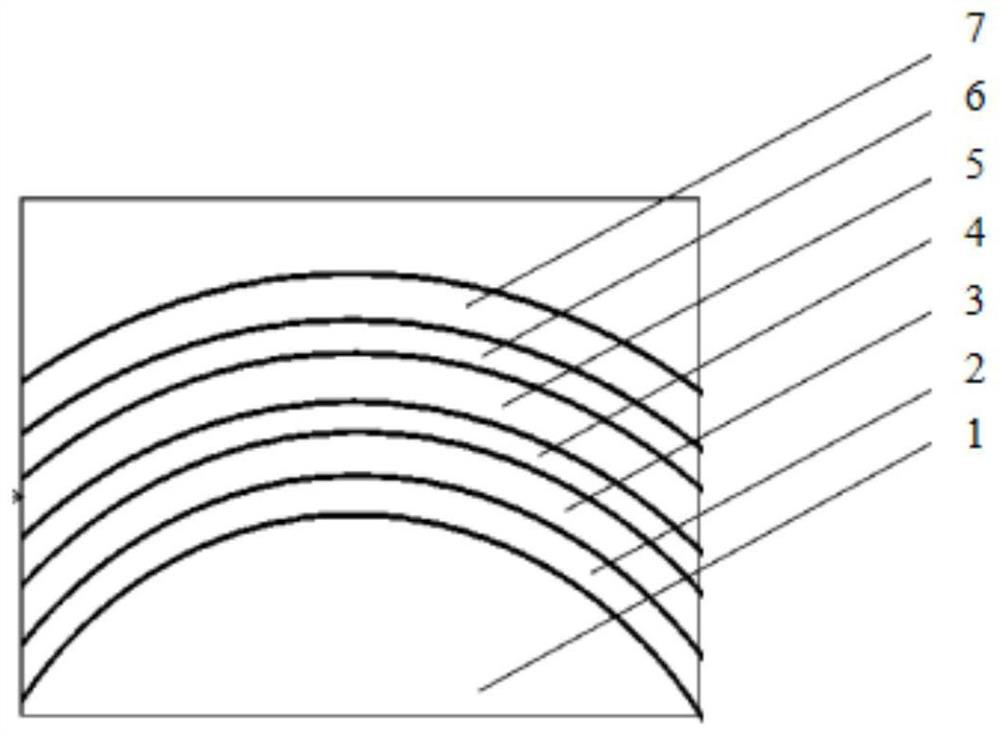

[0032] This embodiment provides a fabric prepared from yarns with electrostatic loading characteristics. The specific structure is a cotton fiber fabric with a plain weave structure. The warp density is 110 threads / 10cm, and the weft density is 90 threads / 10cm. The composition is pure functional cotton fiber, the cotton yarn is the base, and the surface is provided with a multi-layer film structure, such as figure 1 and figure 2 As shown, it includes a cotton yarn base layer 1 and a multi-layer film structure 8 coated on the surface of the cotton yarn base layer 1. The multi-layer film structure 8 is composed of a polydopamine carrier film binding layer I2, a metal Copper conductive layer 3 , polydopamine carrier membrane binding layer II 4 , polypyrrole dielectric layer 5 , polydopamine carrier membrane binding layer III 6 , and polyamide resin protective layer 7 .

[0033] The cotton yarn base layer and the multilayer film structure on the surface are integrated structures...

Embodiment 2

[0035] This embodiment provides a fabric prepared from yarns with electrostatic load characteristics. The specific structure is a warp-knitted polyester fiber fabric with a warp density of 150 threads / 10cm and a weft density of 130 threads / 10cm. The composition is pure functional polyester fibers. Polyester yarn is used as the base, and it is provided with a multi-layer film structure, including a polyester yarn base and a multi-layer film structure covering the surface of the polyester yarn base. Layer Ⅰ (epoxy resin: Huibai New Material Technology, ML-5417A; curing agent: Huibai New Material Technology, ML-5417B; ratio of epoxy resin to curing agent: 10:3), carbon nanotube conductive layer, Epoxy bonding layer II (epoxy resin: Huibai New Material Technology, ML-5417A; curing agent: Huibai New Material Technology, ML-5417B; ratio of epoxy resin to curing agent: 10:3), Ni-ZrO 2 Composition of metal-based ceramic power storage layer and protective layer, Ni-ZrO 2 The metal-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com