Novel volute structure of centrifugal machine

A centrifuge and volute technology, applied in the field of centrifuges, can solve the problems of difficulty in the arrangement of various components of the aerodynamic part of the centrifuge, reduced operating stability of the centrifuge, and lack of versatility, etc., to increase the critical speed, reduce the length, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

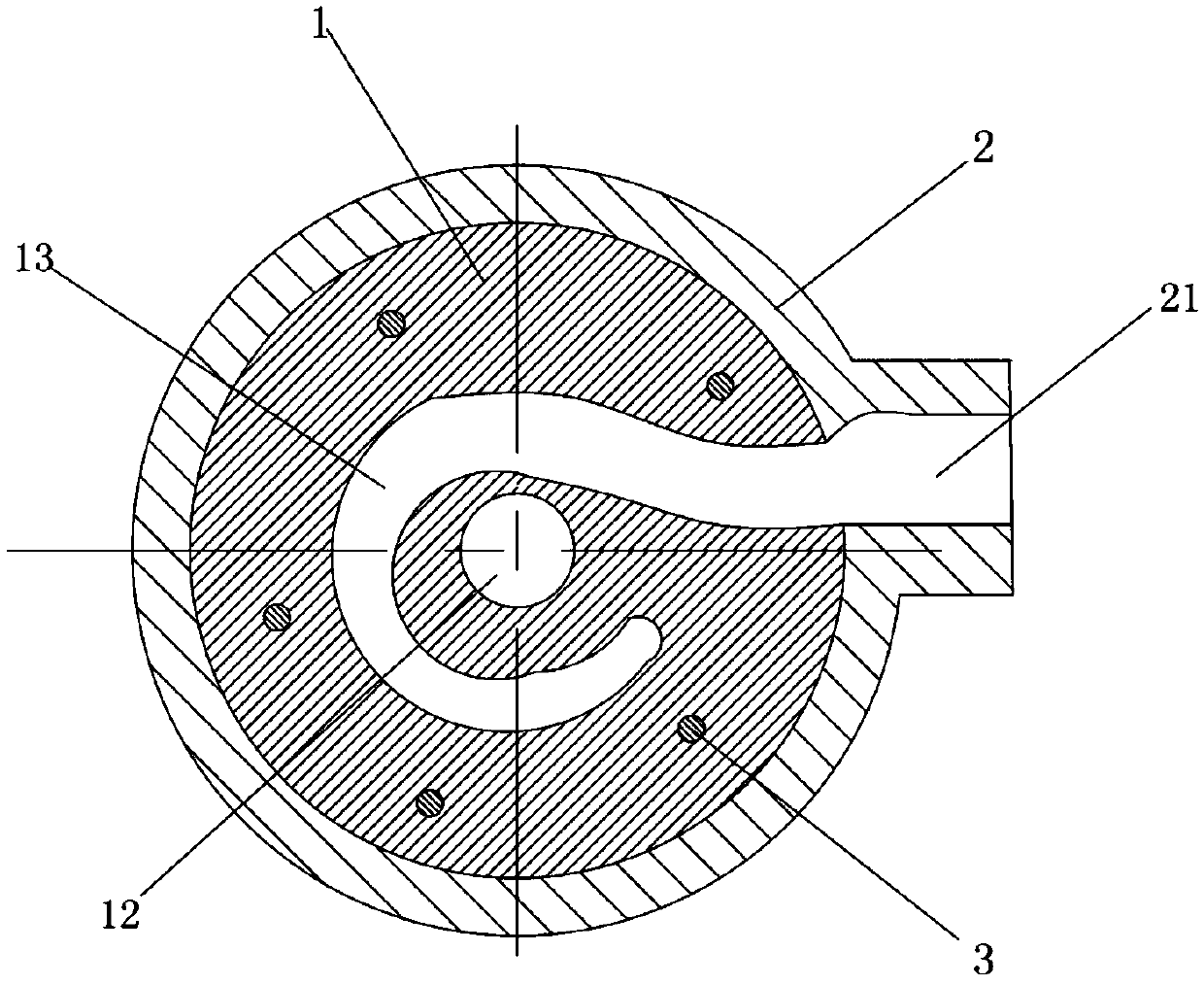

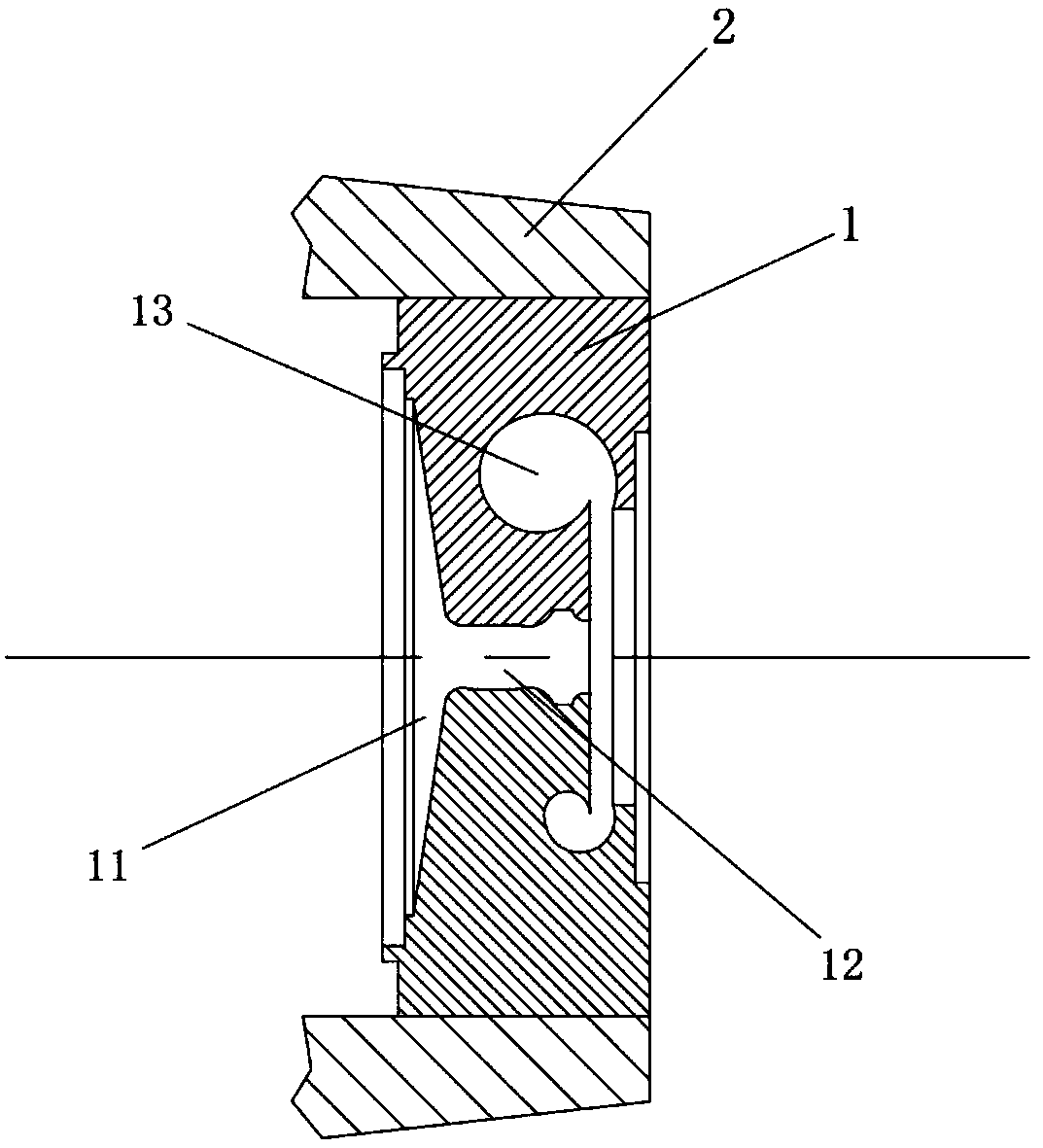

[0027] The volute structure of a new centrifuge, such as figure 1 , figure 2 As shown, it includes an inner volute 1 and an outer volute 2, the cross-sectional shape of the inner volute 1 is circular, and it is arranged in the outer volute 2; the inner volute 1 and the outer volute 2 pass through They are connected into one body in the form of clearance fit, and fixed on the motor casing for transmission by screws 3, so that centrifuges with similar cooling capacity can share the same specification of the outer volute 2; the outer volute 2 is provided with Air outlet channel 21; the inner volute 1 is provided with a relief groove 11 and a relief through hole 12 for the installation of other centrifuge components such as a reflux assembly, a diffuser and an impeller; the relief groove 11 and The through hole 12 is connected; the inner volute 1 is provided with a bend 13, and the cross section of the bend 13 in the direction of the vertical axis is a bilaterally symmetrical vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com