Voltage stabilizing aircraft skin clamping system and method

An aircraft skin and voltage stabilizing technology, which is applied to mechanical equipment, fluid pressure actuators, servo motors, etc., to achieve the effects of smooth commutation, stable commutation and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

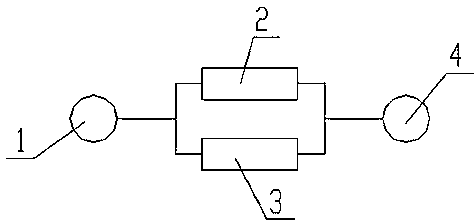

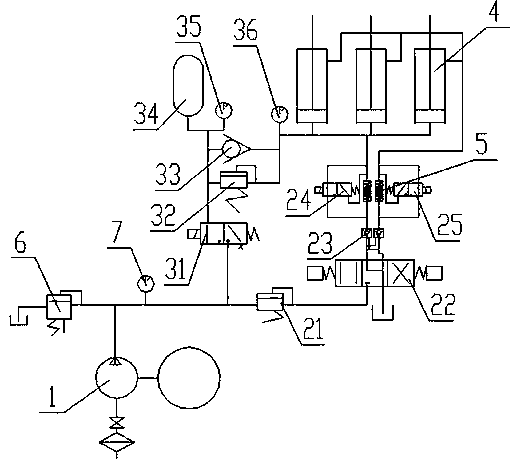

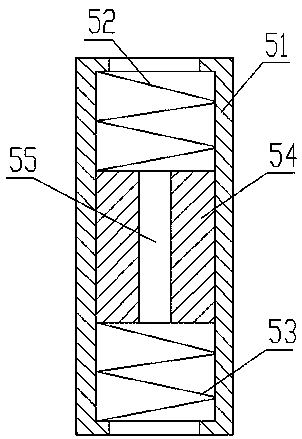

[0040] Such as Figures 1 to 3 As shown, a pressure-stabilizing clamping aircraft skin system includes a hydraulic pump 1 and a hydraulic cylinder 4, and is characterized in that a pressure-stabilizing unit 2 and a pressure-holding unit are arranged in parallel between the hydraulic pump 1 and the hydraulic cylinder 4 3;

[0041] The pressure stabilizing unit 2 includes a decompression valve A21 sequentially connected with the hydraulic pump 1, an electro-hydraulic reversing valve 22 and a hydraulic control check valve 23, and the hydraulic control check valve 23 is connected with an electromagnetic reversing valve A24 and an electromagnetic reversing valve A24. The reversing valve B25, the electromagnetic reversing valve A24 and the electromagnetic reversing valve B25 are arranged side by side, the rodless chamber of the hydraulic cylinder 4 is connected with the electromagnetic reversing valve A24, and the rod chamber of the hydraulic cylinder 4 is connected to the electroma...

Embodiment 2

[0045] Such as Figures 1 to 3 As shown, a pressure-stabilizing clamping aircraft skin system includes a hydraulic pump 1 and a hydraulic cylinder 4, and is characterized in that a pressure-stabilizing unit 2 and a pressure-holding unit are arranged in parallel between the hydraulic pump 1 and the hydraulic cylinder 4 3;

[0046] The pressure stabilizing unit 2 includes a decompression valve A21 sequentially connected with the hydraulic pump 1, an electro-hydraulic reversing valve 22 and a hydraulic control check valve 23, and the hydraulic control check valve 23 is connected with an electromagnetic reversing valve A24 and an electromagnetic reversing valve A24. The reversing valve B25, the electromagnetic reversing valve A24 and the electromagnetic reversing valve B25 are arranged side by side, the rodless chamber of the hydraulic cylinder 4 is connected with the electromagnetic reversing valve A24, and the rod chamber of the hydraulic cylinder 4 is connected to the electroma...

Embodiment 3

[0055] Such as Figures 1 to 3 As shown, a pressure-stabilizing clamping aircraft skin system includes a hydraulic pump 1 and a hydraulic cylinder 4, and is characterized in that a pressure-stabilizing unit 2 and a pressure-holding unit are arranged in parallel between the hydraulic pump 1 and the hydraulic cylinder 4 3;

[0056] The pressure stabilizing unit 2 includes a decompression valve A21 sequentially connected with the hydraulic pump 1, an electro-hydraulic reversing valve 22 and a hydraulic control check valve 23, and the hydraulic control check valve 23 is connected with an electromagnetic reversing valve A24 and an electromagnetic reversing valve A24. The reversing valve B25, the electromagnetic reversing valve A24 and the electromagnetic reversing valve B25 are arranged side by side, the rodless chamber of the hydraulic cylinder 4 is connected with the electromagnetic reversing valve A24, and the rod chamber of the hydraulic cylinder 4 is connected to the electroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com