Gas extraction negative-pressure pipeline leakage detecting device and method

A technology of gas drainage and negative pressure, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of low leakage detection efficiency and inability to locate the leakage point in time, so as to achieve safety hazards without electrification and no leakage Potential safety hazards and the effect of reducing gas explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

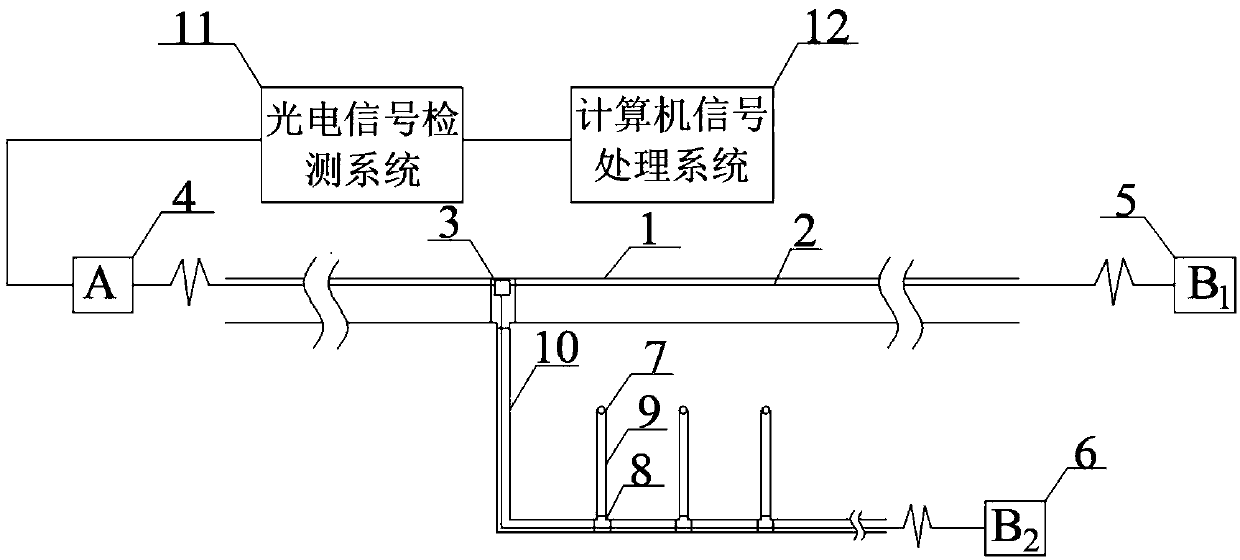

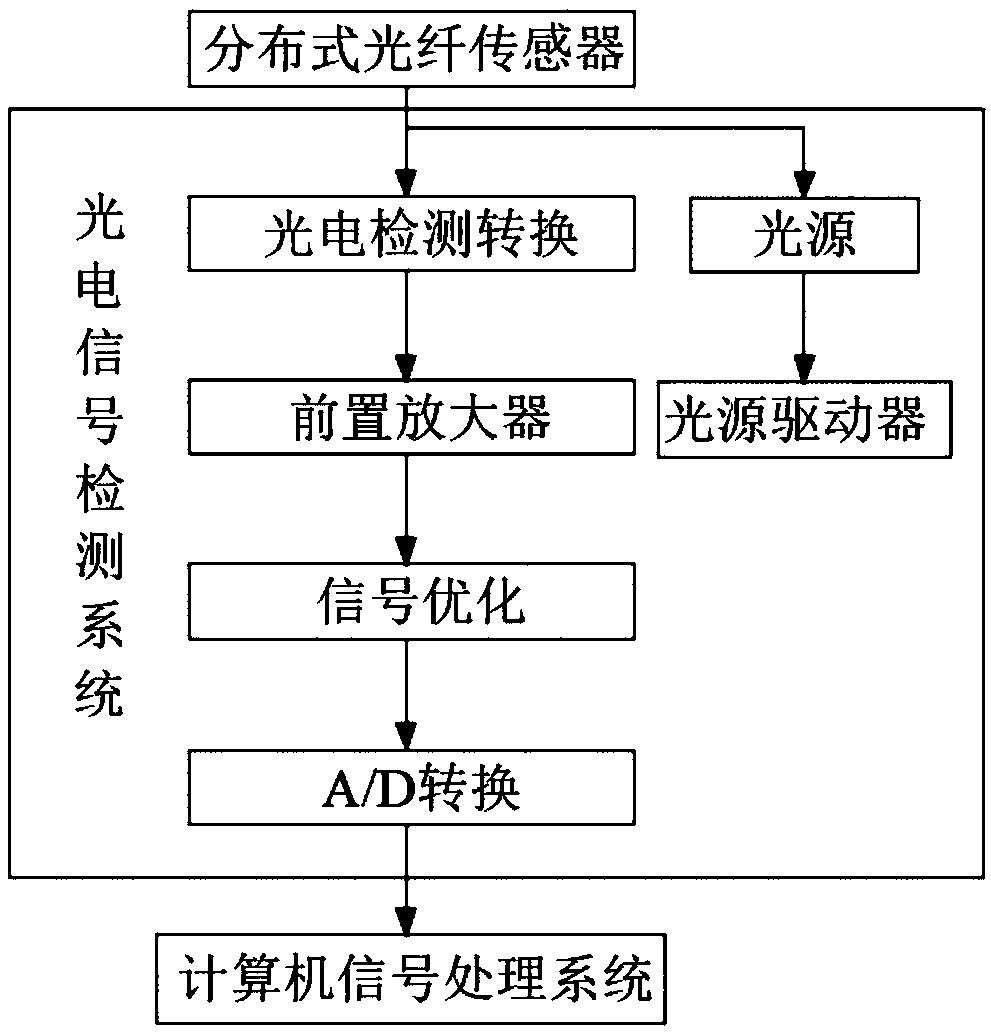

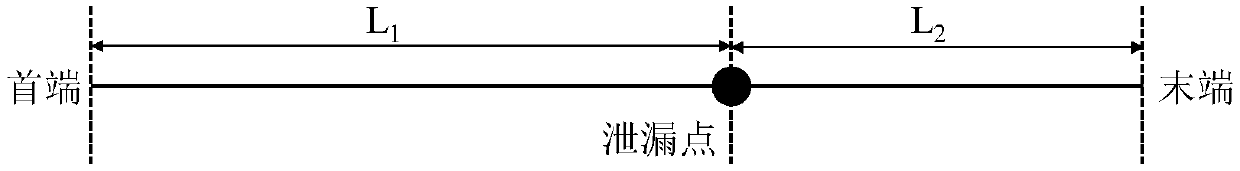

[0025] Such as figure 1 As shown, a gas drainage negative pressure pipeline leakage detection device includes a distributed optical fiber sensor 2 , a head-end coupler 4 , a Faraday rotating mirror, a photoelectric signal detection system 11 and a computer signal processing system 12 . The distributed optical fiber sensor 2 is arranged in the gas drainage negative pressure pipeline, which includes the gas drainage main pipe 1 and the gas drainage branch pipe 10, and the Faraday rotating mirror includes Faraday rotating mirror 1 5 and Faraday rotating mirror 2 6. The end of the distributed optical fiber sensor in the gas drainage main pipe 1 is equipped with a Faraday rotating mirror 1, the end of the distributed optical fiber sensor in the gas drainage branch pipe 10 is equipped with a Faraday rotating mirror 2 6, and the distributed optical fiber in the gas drainage branch pipe 10 The sensor is connected to the distributed optical fiber sensor in the gas drainage main pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com