Outer rotor flux switching motor with high permanent-magnet utilization rate

A technology of magnetic flux switching motors and outer rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electric components, etc., can solve the problem of increased self-inductance of armature windings, magnetic flux leakage from the outer circle of motor stators, and low utilization of permanent magnets in motors To achieve the effect of increasing the magnetic flux density and power, increasing the magnetic potential of the magnetic circuit, and improving the utilization rate of the permanent magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

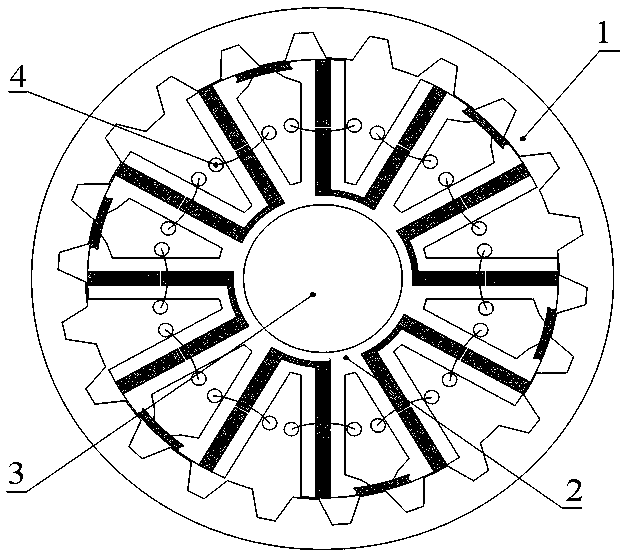

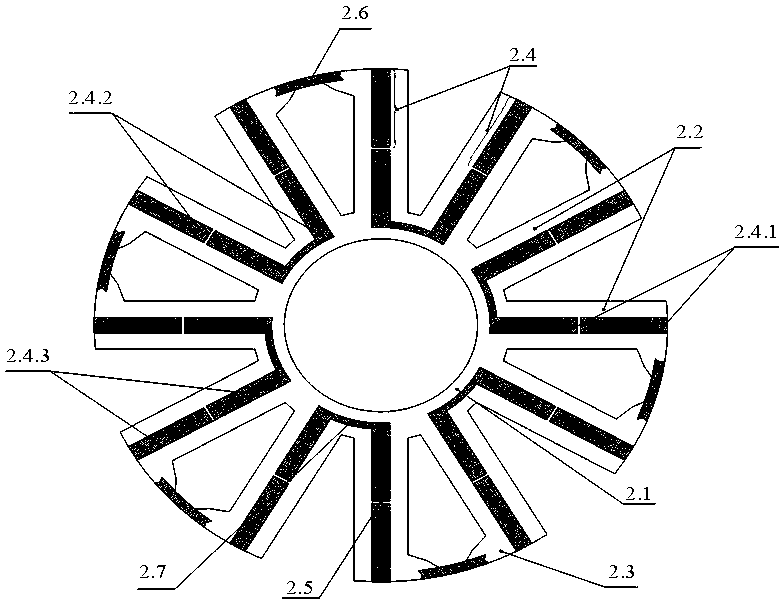

[0027] see figure 1 , the present invention includes a rotor 1 , a stator 2 , a shaft 3 and a concentrated winding 4 . The stator 2 is coaxially located inside the rotor 1 , and the center of the stator 2 is used to place the rotating shaft 3 . There is an air gap between the inner wall of rotor 1 and the outer wall of stator 2. The thickness of the air gap is related to the power level of the motor, the selected permanent magnet material, and the processing and assembly process of rotor 1 and stator 2. Both rotor 1 and stator 2 have a thickness of 0.35 It is made of laminated silicon steel sheets with a thickness of mm, and the lamination coefficient is 0.95.

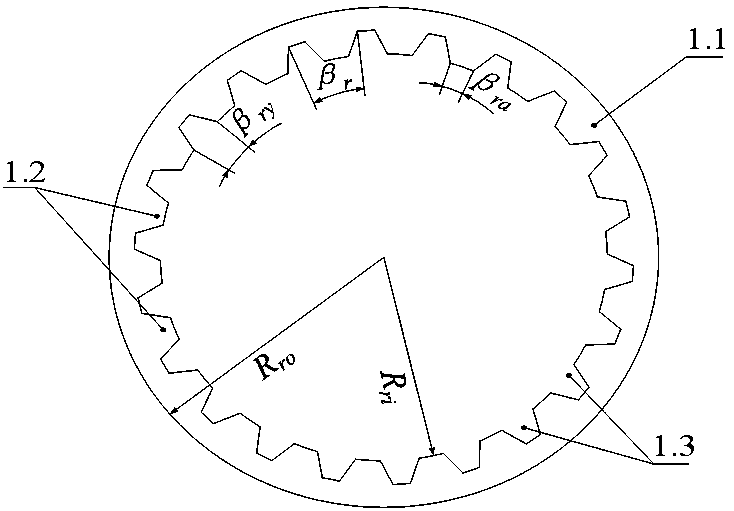

[0028] see figure 2 , the rotor 1 belongs to the salient pole structure in structure, and there is neither permanent magnet nor winding on the rotor 1. Rotor 1 consists of rotor yoke 1.1, N r Composed of a rotor salient pole 1.2 and a rotor slot 1.3, N r The rotor salient poles 1.2 are evenly distributed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com