Automatic forage chopping equipment with convenient discharging function for breeding industries

A breeding industry, convenient technology, applied in cutting equipment, application, agriculture, etc., can solve the problems of perishable, time-consuming and labor-intensive cutting, inconvenient transportation of products, etc., to improve the crushing effect, increase the crushing area, and reduce the degree of manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

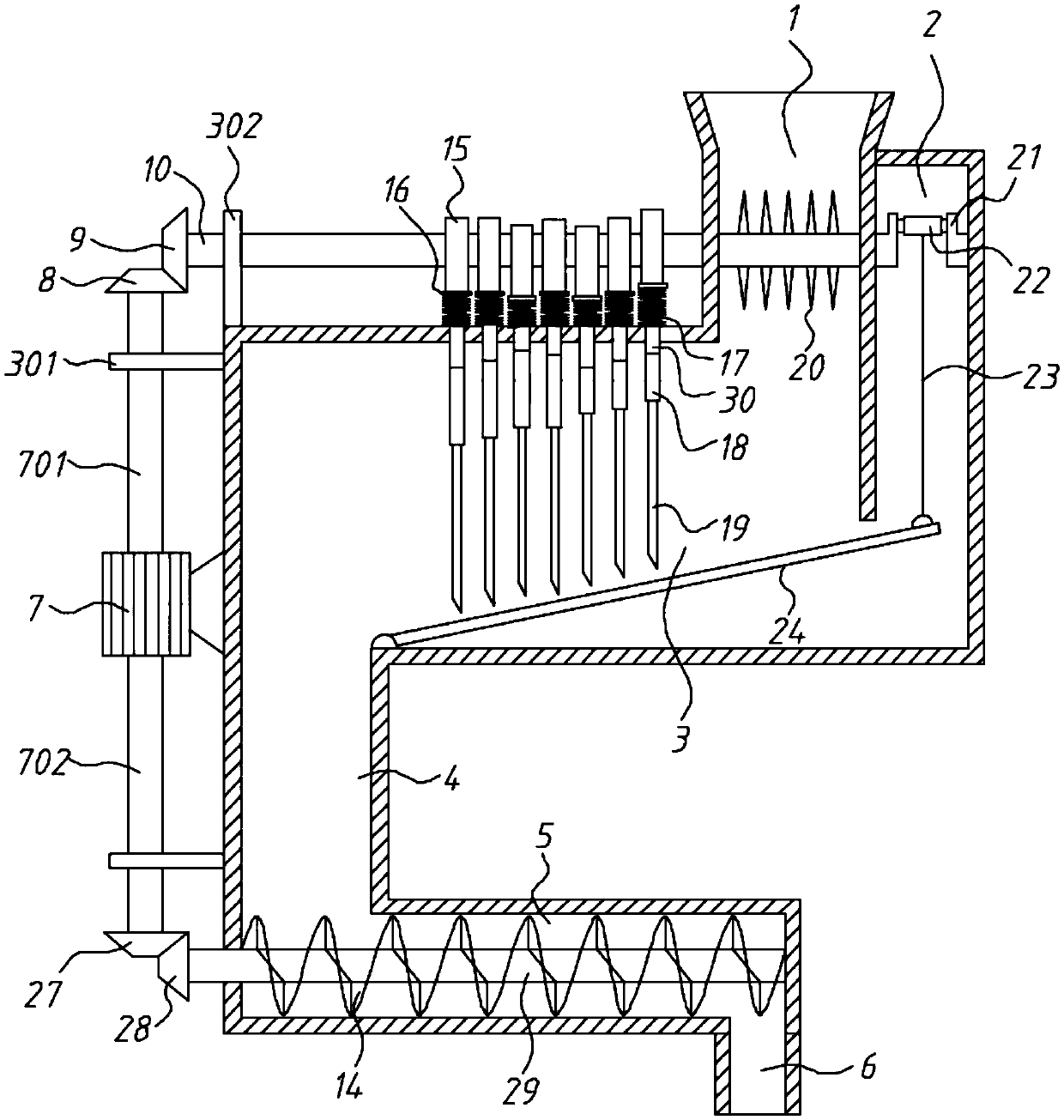

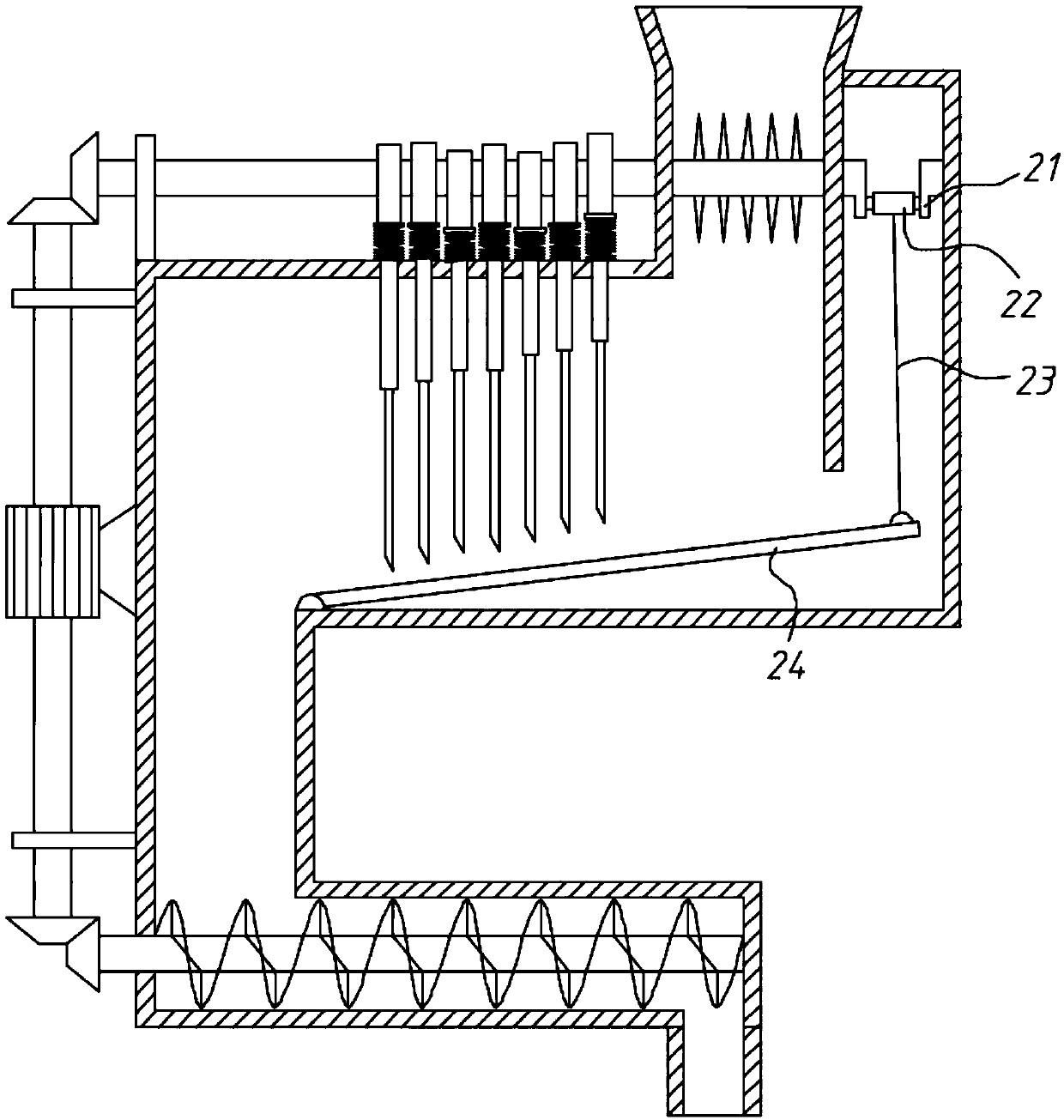

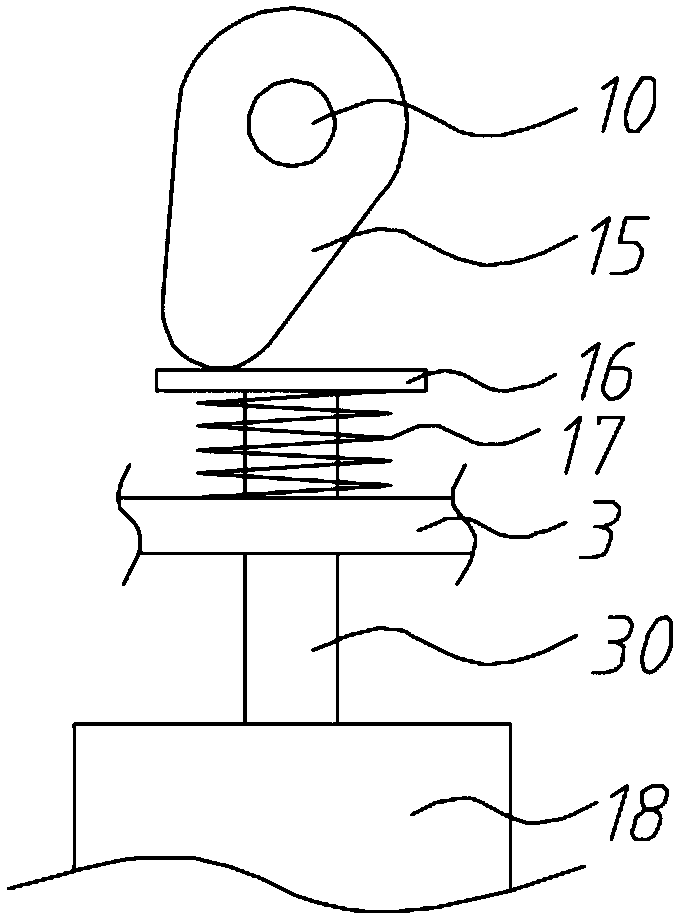

[0044] A convenient discharging type forage automatic shredding equipment for aquaculture, comprising a feeding hopper 1, a pulling chamber 2, a cutting chamber 3, a feeding chamber 4 and a feeding chamber 5;

[0045] The feeding hopper 1 and the pulling chamber 2 are set at the upper right end of the cutting chamber 3, and the bottom is connected to the cutting chamber 3; 10 is evenly equipped with crushing knives 20; the first shaft 10 passes through the feed hopper 1 to the left and is provided with multiple groups of cam assemblies 15, and the lower part of the cam assemblies 15 is correspondingly provided with a cutting assembly; the left end of the first shaft 10 extends to the cutting chamber 3 The left side is connected with the No. 2 bevel gear 9; the No. 1 shaft 10 extends into the pulling chamber 2 to the right and is provided with a bell crank 21. The bell crank 21 is fitted with a sleeve 22, and the sleeve 22 is connected downward with a Wire rope 23;

[0046] Th...

Embodiment 2

[0054] A convenient discharging type forage automatic shredding equipment for aquaculture, comprising a feeding hopper 1, a pulling chamber 2, a cutting chamber 3, a feeding chamber 4 and a feeding chamber 5;

[0055] The feeding hopper 1 and the pulling chamber 2 are set at the upper right end of the cutting chamber 3, and the bottom is connected to the cutting chamber 3; 10 is evenly equipped with crushing knives 20; the first shaft 10 passes through the feed hopper 1 to the left and is provided with multiple groups of cam assemblies 15, and the lower part of the cam assemblies 15 is correspondingly provided with a cutting assembly; the left end of the first shaft 10 extends to the cutting chamber 3 The left side is connected with the No. 2 bevel gear 9; the No. 1 shaft 10 extends into the pulling chamber 2 to the right and is provided with a bell crank 21. The bell crank 21 is fitted with a sleeve 22, and the sleeve 22 is connected downward with a Wire rope 23;

[0056] Th...

Embodiment 3

[0066] A convenient discharging type forage automatic shredding equipment for aquaculture, comprising a feeding hopper 1, a pulling chamber 2, a cutting chamber 3, a feeding chamber 4 and a feeding chamber 5;

[0067] The feeding hopper 1 and the pulling chamber 2 are set at the upper right end of the cutting chamber 3, and the bottom is connected to the cutting chamber 3; 10 is evenly equipped with crushing knives 20; the first shaft 10 passes through the feed hopper 1 to the left and is provided with multiple groups of cam assemblies 15, and the lower part of the cam assemblies 15 is correspondingly provided with a cutting assembly; the left end of the first shaft 10 extends to the cutting chamber 3 The left side is connected with the No. 2 bevel gear 9; the No. 1 shaft 10 extends into the pulling chamber 2 to the right and is provided with a bell crank 21. The bell crank 21 is fitted with a sleeve 22, and the sleeve 22 is connected downward with a Wire rope 23;

[0068] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com