Repairing method for side slope of mine dump

A restoration method and technology of dumping sites, applied in botany equipment and methods, horticulture, agriculture, etc., can solve the problems of unsatisfactory green restoration effect, easy degradation, large bald spot area, etc., and reduce the collective death of seedlings in a large area risk, reduce interspecific competition, and reduce the effect of intraspecific competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

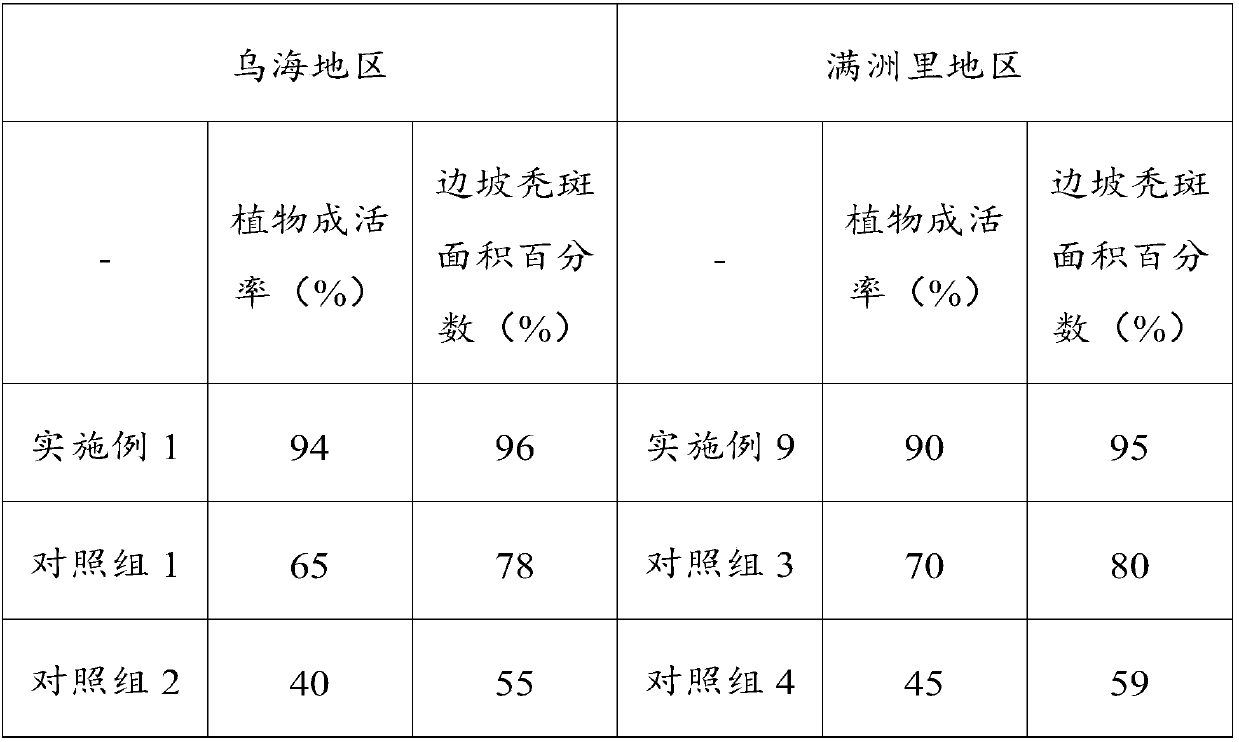

Embodiment 1

[0044] Taking the side slope of a mine dump in Wuhai area as the site to be repaired, before planting, set up intercepting ditches and sumps on each step platform of the side slope for drainage, and set up platform concealed pipes to dredge step by step. Surface-buried drainage pipes are connected to the intercepting ditch for drainage.

[0045] In mid-April, using the layered spraying method, plant 0.7 parts by weight of Bawang, 1.1 parts by weight of holly and 2.7 parts of mountain peach on the bottom layer, plant 0.3 parts by weight of red sand and 0.3 parts by weight of quadruple wood in the middle layer , the Tibetan caragana of 0.1 weight part, the Nitraria japonica of 0.3 weight part and the camel thorn of 0.3 weight part, the surface planting 0.2 weight part of Artemisia annua, 0.4 weight part of shallot, 0.9 weight part of wild leek, 0.3 weight part of Multiple spring onions, 0.7 parts by weight of Satawan, 0.3 parts by weight of sweet clover and 0.1 parts by weight o...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] The proportion of various seeds is: 1.6 parts by weight of Bawang, 3.6 parts by weight of mountain peach, 0.7 parts by weight of red sand, 0.7 parts by weight of quadrangle wood, 2.5 parts by weight of sand holly, 0.3 parts by weight of Caragana japonica, 0.7 parts by weight of Nitraria, 0.7 parts by weight of camel thorn, 0.4 parts by weight of Artemisia annua, 0.8 parts by weight of shallots, 2 parts by weight of wild leeks, 0.7 parts by weight of multi-rooted shallots, 1.4 parts by weight of sandwort, 0.7 parts by weight of sweet clover and 0.3 parts by weight of Oxytropis.

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is:

[0052] The ratio of various seeds is: 0.9 parts by weight of Bawang, 3.5 parts by weight of mountain peach, 0.4 parts by weight of red sand, 0.6 parts by weight of quadrangle wood, 1.5 parts by weight of sand holly, 0.25 parts by weight of Tibetan caragana, 0.4 parts by weight of Nitraria, 0.6 parts by weight of camel thorns, 0.25 parts by weight of Artemisia annua, 0.7 parts by weight of shallots, 1.2 parts by weight of wild leeks, 0.6 parts by weight of multi-rooted shallots, 0.8 parts by weight of sandwort, 0.6 parts by weight of sweet clover and 0.15 parts by weight of Oxytropis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com