a wire drawing machine

A wire drawing machine and wire drawing technology, which is applied in the field of wire drawing machines, can solve the problems of difficulty in wire threading, the operator spends a lot of effort, etc., and achieve the effects of facilitating preliminary thinning, good wire drawing effect and improving feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

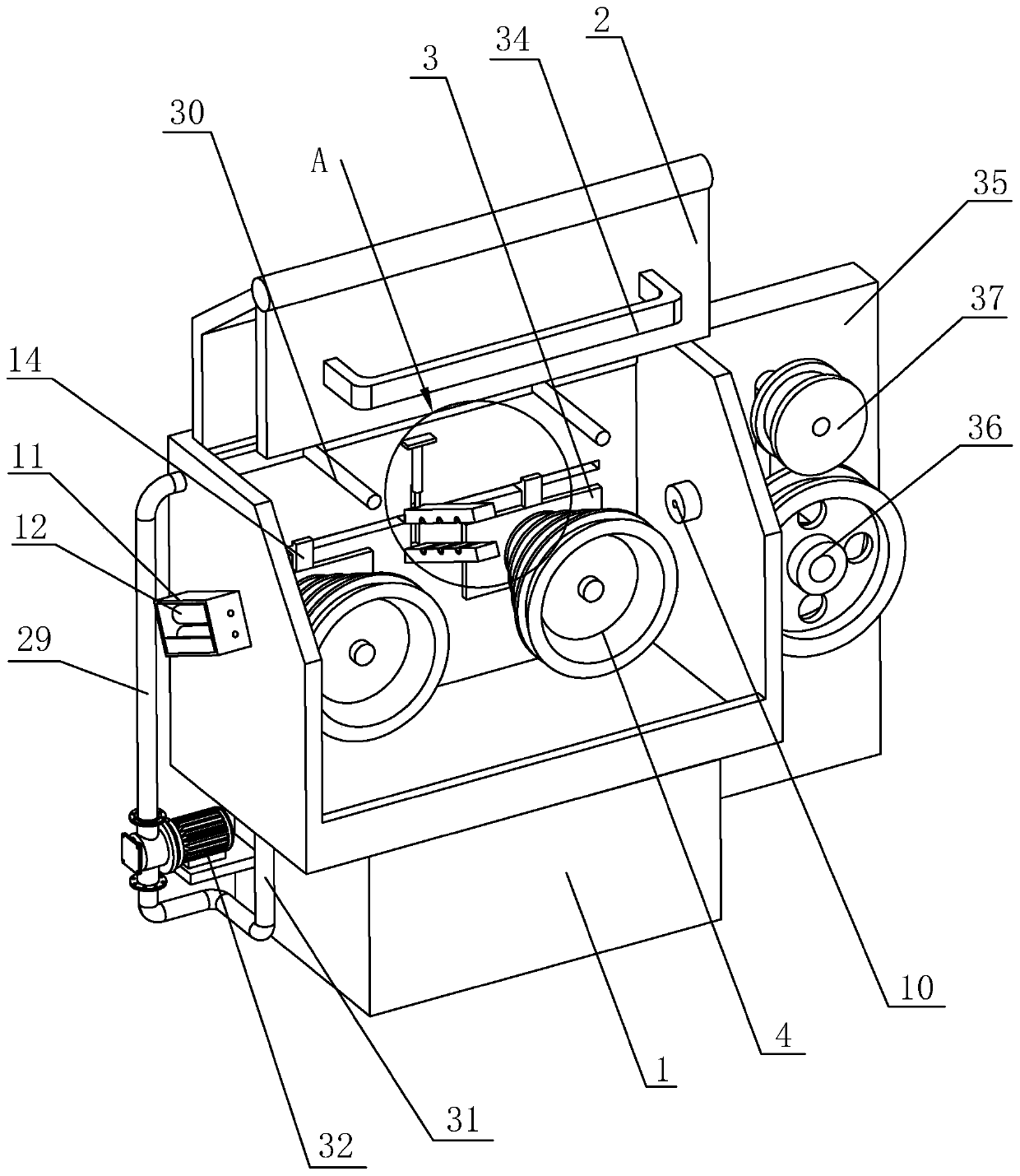

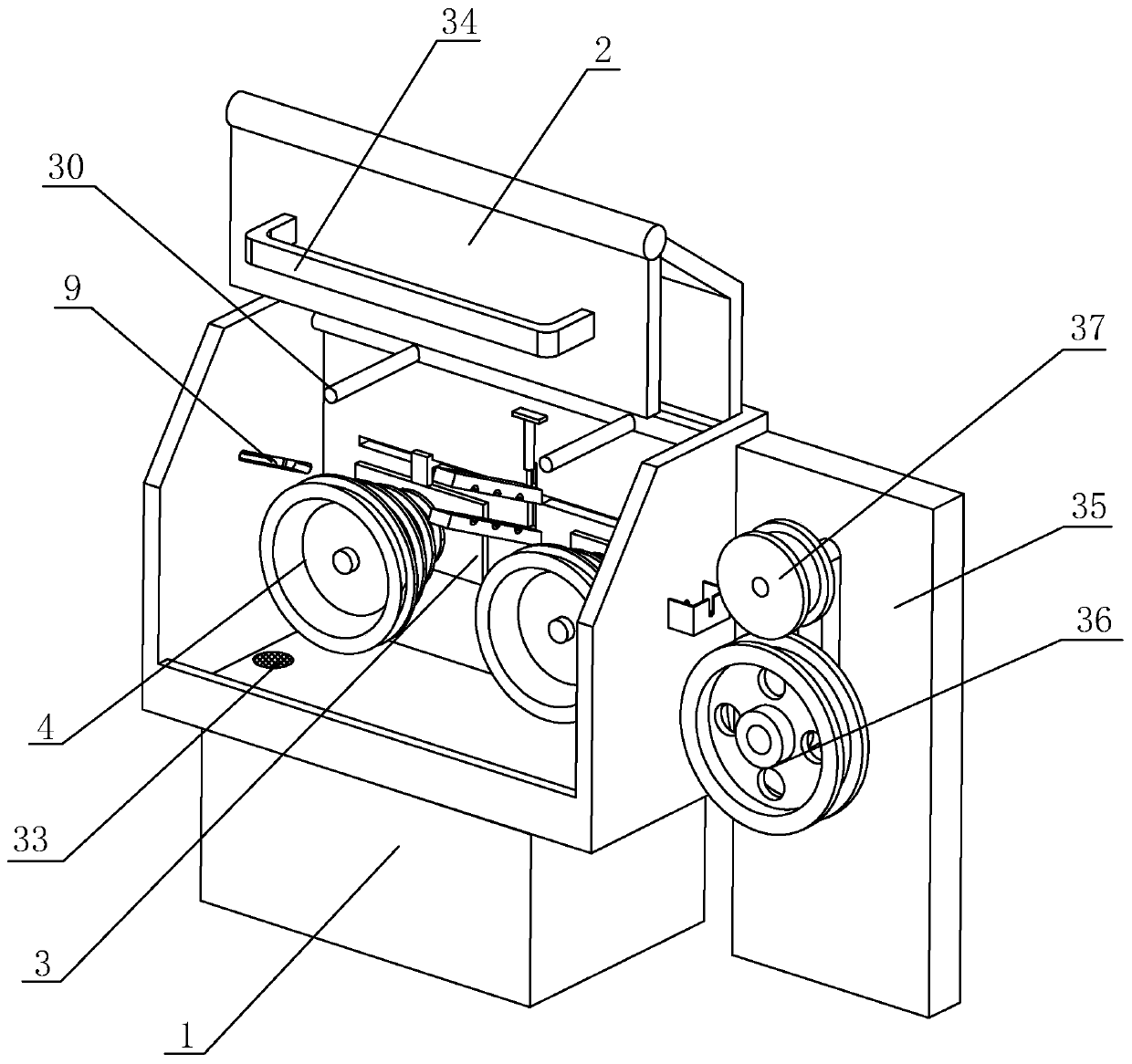

[0038] refer to figure 1 , is a wire drawing machine disclosed in the present invention, comprising a casing 1 with an open structure on the upper end surface, the opening of the casing 1 is hingedly connected with an organic cover 2, the cover 2 is two plates and the plates are hingedly connected, the machine A handle 34 is fixed on the outer wall of the cover 2 . The handle 34 is convenient for the operator to open the machine cover 2 .

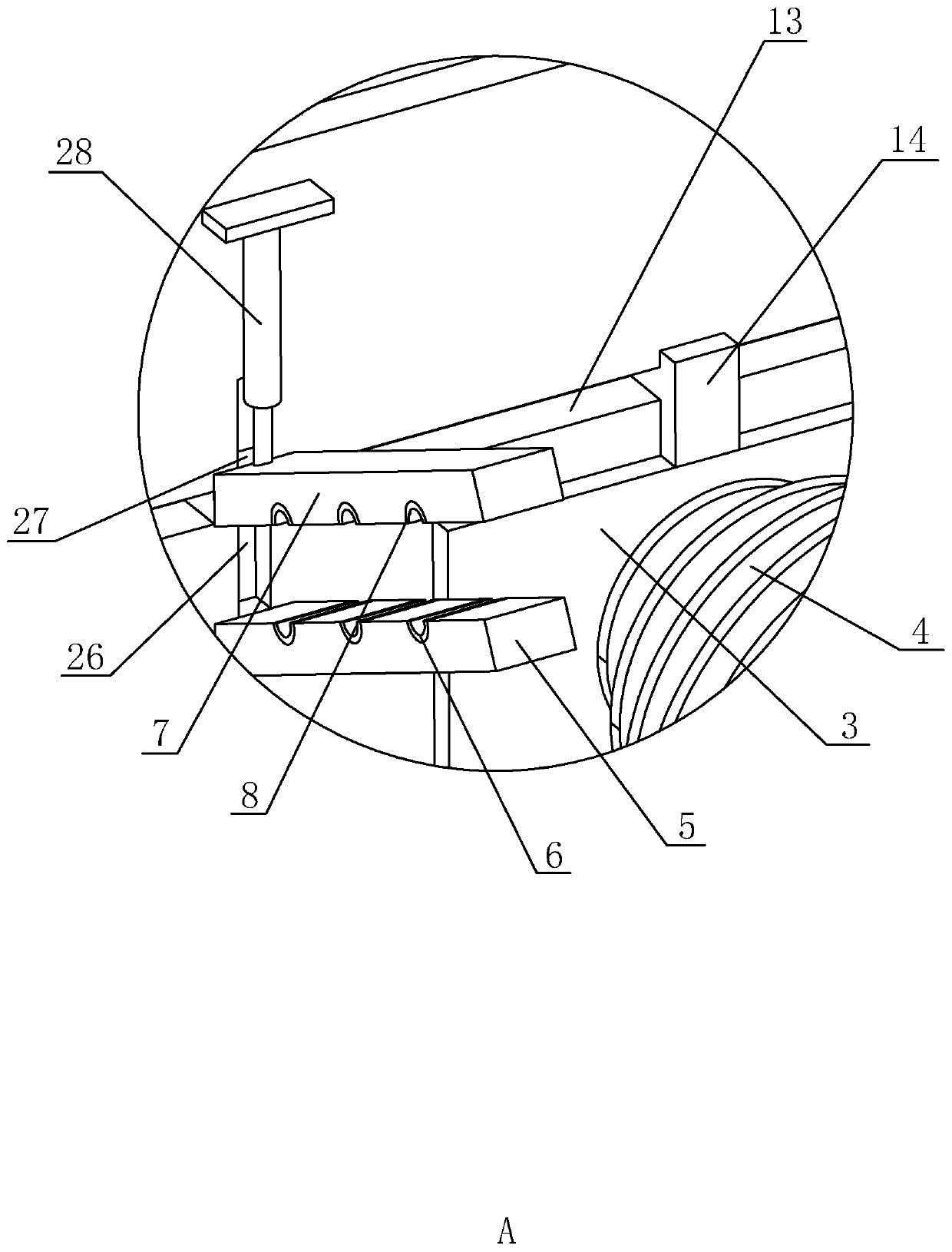

[0039] refer to figure 1 and figure 2 , an inner wall of the casing 1 is provided with two sliding seats 3 for relative sliding, the side wall of the casing 1 is provided with a horizontally arranged transverse groove 13, and the transverse groove 13 is located on the side of the casing 1 away from its opening, and the sliding seat 3 The top end is fixed with a slide block 14 which slides and adapts to the transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com