Drill bit and diamond thin-wall drill

A drill bit and drilling rig technology, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve problems such as broken teeth, easy cracking, and weakening of bending strength, etc., to achieve good corrosion resistance and reduce matrix The effect of cracked or broken teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

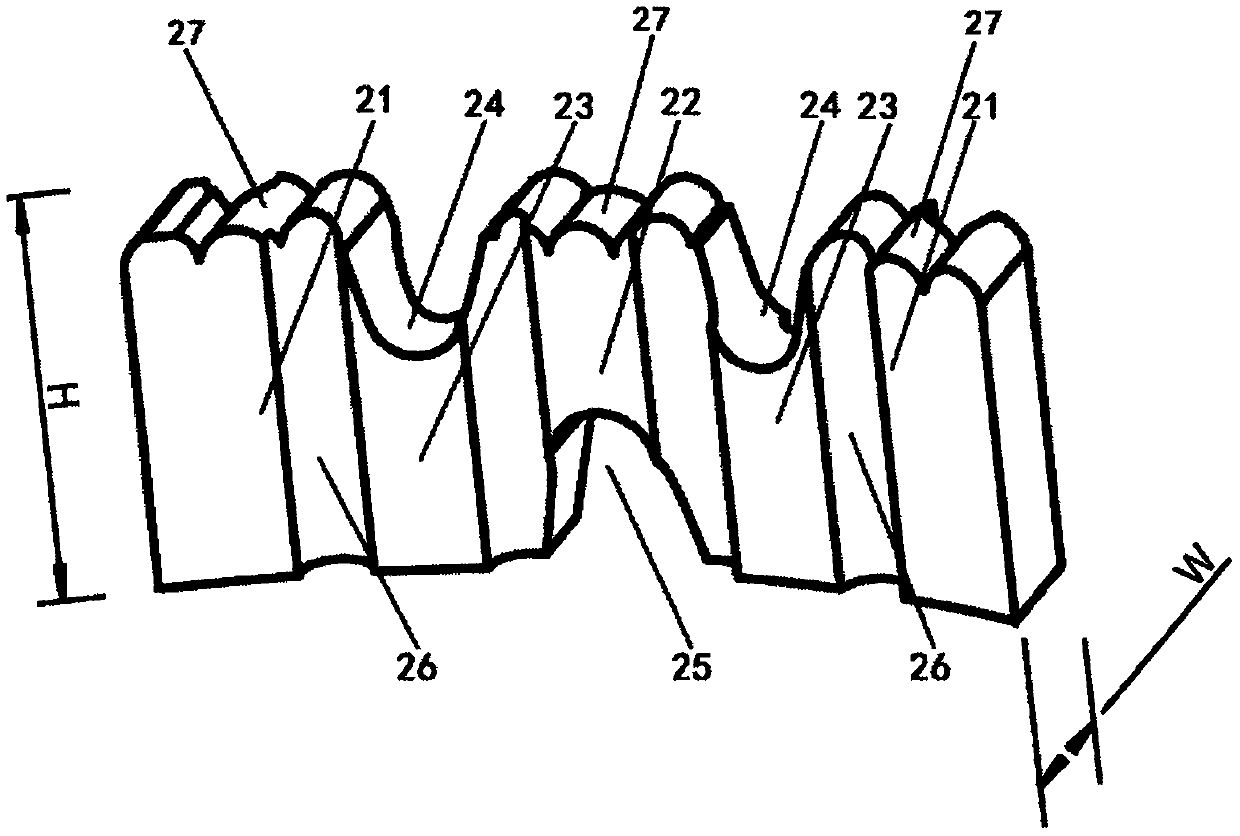

Image

Examples

Embodiment 1

[0023]The composition of the metal bond used is: 15wt% electrolytic copper powder, 3wt% atomized tin powder, 8wt% carbonyl nickel powder, 10wt% FeCoCu ultrafine alloy powder, 10wt% FeCuNiSn ultrafine alloy powder, 3wt% % of high chromium cast iron powder and the balance of electrolytic iron powder. Diamond is used as the hard particles, and the strength of the diamond particles is 40 kg, the particle size is 30 / 40, and the concentration is 35%. The diamond and metal bond are mixed evenly in a high-speed mixer, pressure-formed in a tooling mold to form a billet, and sintered in a resistance heating furnace, and in N 2 Insulate at 870°C for 60min under protective atmosphere.

Embodiment 2

[0025] The composition of the metal bond used is: 25wt% electrolytic copper powder, 5wt% atomized tin powder, 3wt% carbonyl nickel powder, 5wt% FeCoCu superfine alloy powder, 20wt% FeCuNiSn superfine alloy powder, 5wt% % of high chromium cast iron powder and the balance of electrolytic iron powder. Diamond is used as the hard particles, and the strength of the diamond particles is 40 kg, the particle size is 30 / 40, and the concentration is 35%. The diamond and metal bond are mixed evenly in a high-speed mixer, pressure-formed in a tooling mold to form a billet, and sintered in a resistance heating furnace, and in N 2 Insulate at 870°C for 60min under protective atmosphere.

Embodiment 3

[0027] The composition of the metal binder used is: 20wt% electrolytic copper powder, 4wt% atomized tin powder, 6wt% carbonyl nickel powder, 10wt% FeCoCu ultrafine alloy powder, 18wt% FeCuNiSn ultrafine alloy powder, 8wt% % of high chromium cast iron powder and the balance of electrolytic iron powder. Diamond is used as the hard particles, and the strength of the diamond particles is 40 kg, the particle size is 30 / 40, and the concentration is 35%. The diamond and metal bond are mixed evenly in a high-speed mixer, pressure-formed in a tooling mold to form a billet, and sintered in a resistance heating furnace, and in N 2 Insulate at 870°C for 60min under protective atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com