Sulfuric acid storage tank breathing valve with drying function

A technology for sulfuric acid storage tanks and drying functions, which is applied in tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of easy corrosion of sulfuric acid storage tanks, prolong the service life of sulfuric acid storage tanks, etc., to increase the service life and reduce the number of replacements. , the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

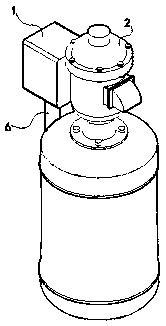

[0033] Such as figure 1 As shown, a breathing valve for a sulfuric acid storage tank with a drying function is characterized by being composed of a drying box 1, a dew point sensor, an alarm, a high-efficiency desiccant, and a breathing valve 2.

[0034] A breathing valve 2 is provided on the top of the sulfuric acid storage tank, and a drying box 1 is provided on the breathing valve 2.

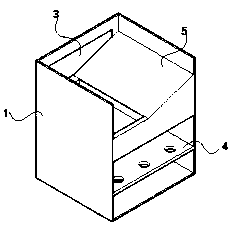

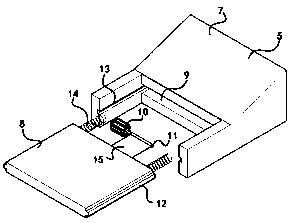

[0035] Such as figure 2 As shown, the rear end of the drying box 1 is hinged with a cover 3, the drying box 1 is provided with a perforated partition 4, the perforated partition 4 is provided with a first dew point sensor, and the top of the perforated partition 4 is filled with efficient desiccant , The replacement part 5 is arranged above the perforated partition 4, the drying box 1 is equipped with an alarm, the drying box 1 is connected to the sulfuric acid storage tank through a pipe 6, one end of the pipe 6 is connected to the drying box 1 through a solenoid valve, and the pipe 6 A second d...

Embodiment 2

[0050] The structure of the breathing valve of the sulfuric acid storage tank is the same as that described in Example 1.

[0051] The preparation of the above-mentioned high-efficiency desiccant includes the following steps:

[0052] (1) Rinse 20 parts of silica gel in deionized water for 10 minutes, then dry it under hot air at 60°C, and then naturally cool to room temperature.

[0053] (2) Put the silica gel into the reaction kettle, raise the temperature to 150°C, slowly add 4 parts of lithium chloride solution and stir and mix with the silica gel, filter and dry at 90°C for 5 hours, then raise the temperature to 130°C, Grade drying for 20 minutes, grinding to obtain modified silica gel.

[0054] (3) The modified silica gel is heated to 90°C, mixed with 11 parts of anhydrous magnesium sulfate, and discharged by a screw extruder. After being cut by a blanking machine, it is granulated by a granulator and sieved (4) Purpose) to obtain the finished desiccant.

Embodiment 3

[0056] The structure of the breathing valve of the sulfuric acid storage tank is the same as that described in Example 1.

[0057] The preparation of the above-mentioned high-efficiency desiccant includes the following steps:

[0058] (1) After washing 26 parts of silica gel in deionized water for 7 minutes, dry it under hot air at 70°C, and then naturally cool to room temperature.

[0059] (2) Put the silica gel into the reaction kettle, raise the temperature to 120°C, slowly add 7 parts of lithium chloride solution and stir and mix with the silica gel, after filtering, carry out primary drying at 100°C for 4h, then raise the temperature to 125°C, Dry for 30 minutes and grind to obtain modified silica gel.

[0060] (3) The modified silica gel is heated to 85°C, mixed with 16 parts of anhydrous magnesium sulfate, and discharged by the screw extruder. After being cut by the feeder, it is granulated by the granulator and passed through a sieve (5 Purpose) to obtain the finished desicca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com