Device for automatic conveying distribution of heating-up furnace glassware

A glassware, automatic transmission technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of product quality impact, high labor cost, easy to leave fingerprints, etc., to reduce staff participation and improve product quality The effect of improving the pass rate and improving the utilization rate of electric heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

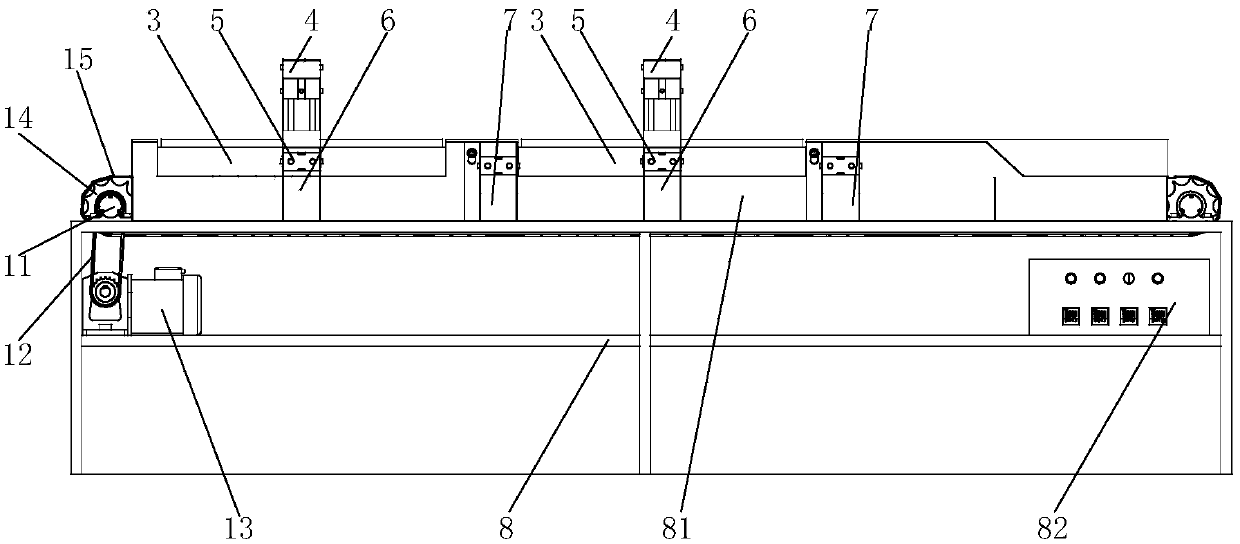

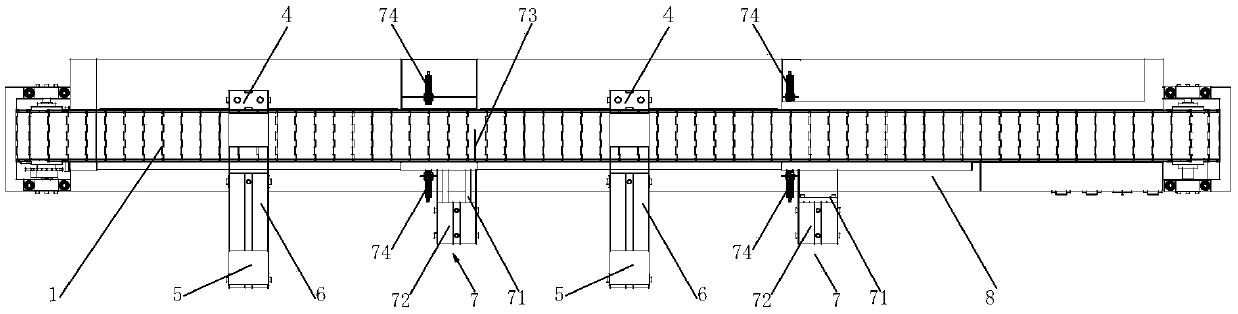

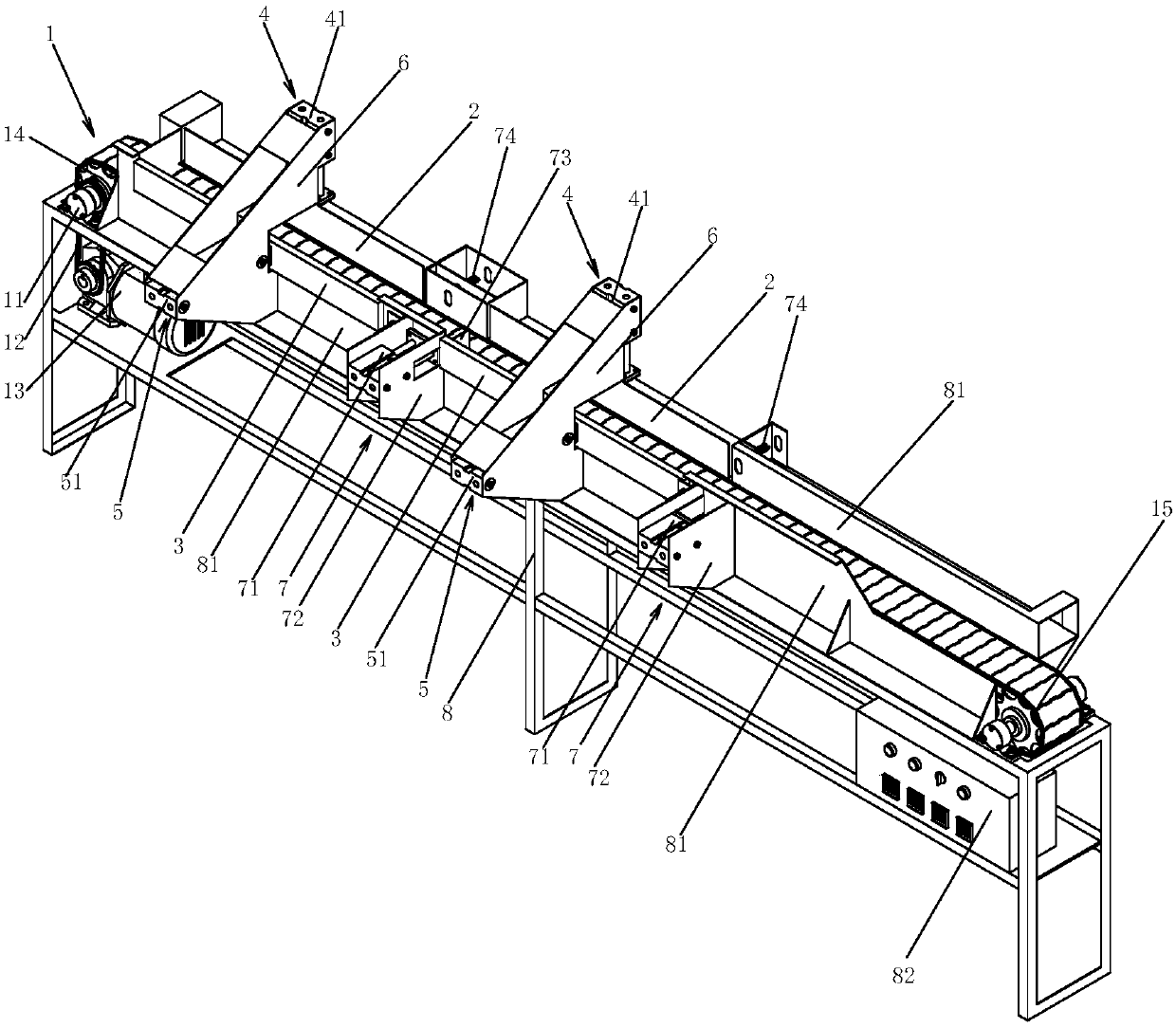

[0017] combined with Figure 1~4 The present invention is further described:

[0018] An automatic transmission and distribution device for glassware in a kiln, comprising a conveying line 1 arranged beside the input port of the kiln and parallel to the input port of the kiln, one side of the conveying line 1 in the length direction is provided with a shutter 2. The other side is provided with a push plate 3, and the side of the conveying line 1 arranged with the shutter 2 is close to the input port of the kiln; it also includes a vertical displacement drive mechanism 4 and a horizontal displacement drive mechanism 5. The linear displacement driving mechanism 4 drives the gate plate 2 to move up and down along the direction perpendicular to the conveying line 1 , and the horizontal displacement driving mechanism 5 drives the push plate 3 to perform horizontal displacement along the width direction of the conveying line 1 . In the above technical solution, the conveying line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com