Sludge drying equipment and sludge drying method

A sludge drying and equipment technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problem of high operating energy consumption, complex drying equipment, consumption of Big energy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

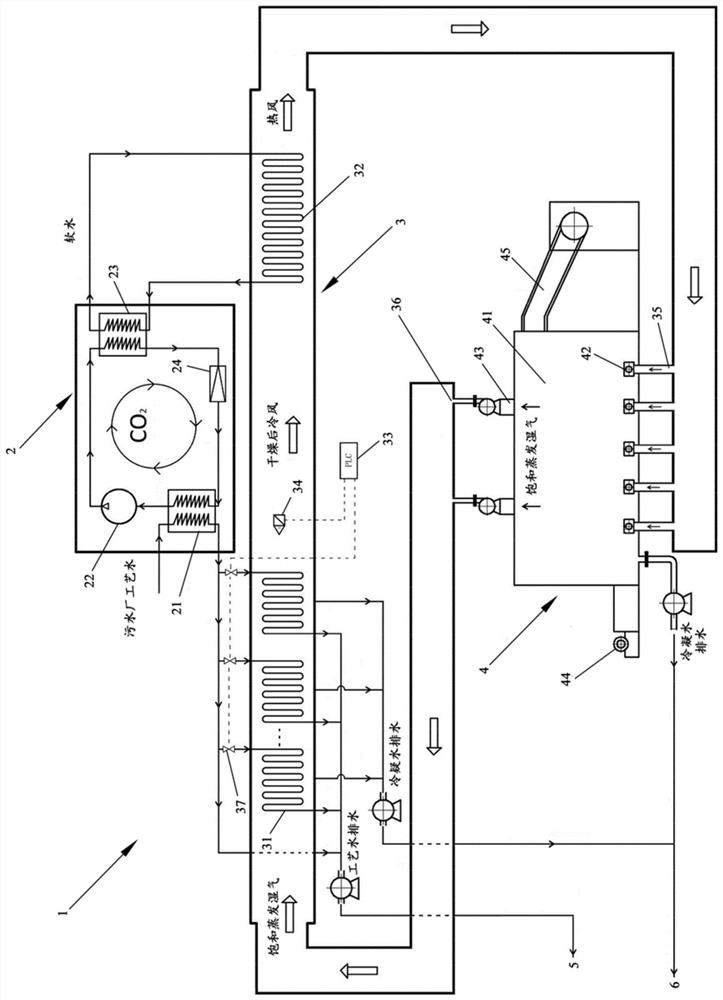

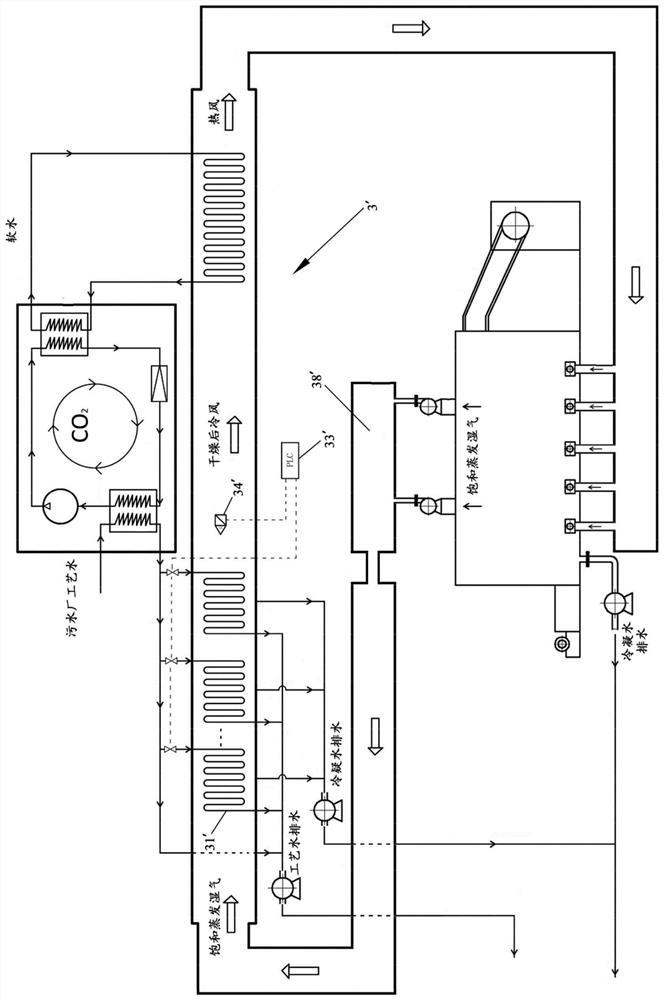

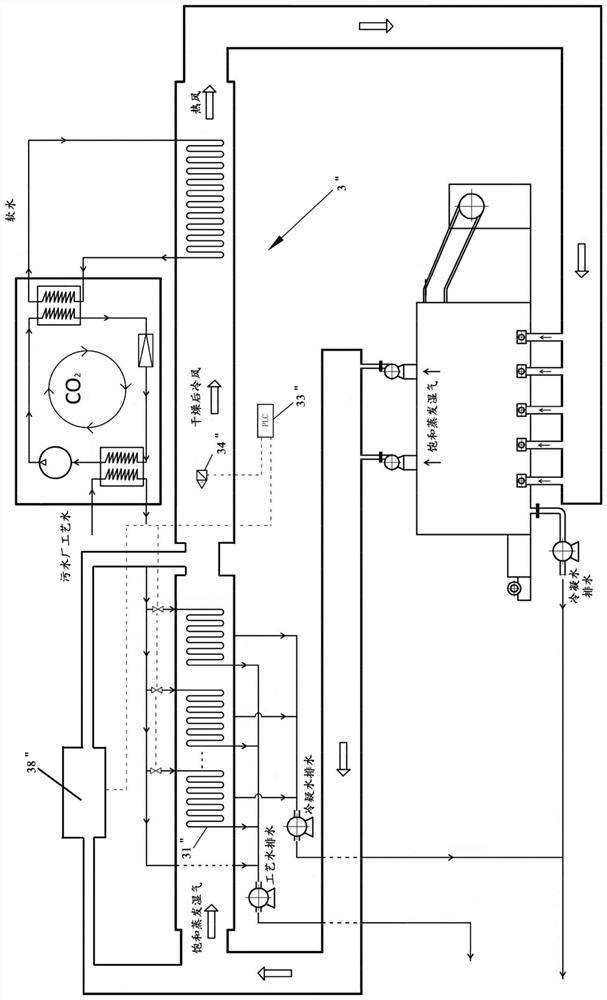

[0041] figure 1 A preferred embodiment of a sludge drying plant 1 according to the invention is shown. The sludge drying equipment 1 includes a heat pump 2 , a gas regulating device 3 and a drying device 4 .

[0042] exist figure 1 In the preferred embodiment described above, the heat pump 2 is a carbon dioxide heat pump, and carbon dioxide circulates in the heat pump 2 as a refrigerant. The mode of operation of the heat pump is described as an example as follows. The carbon dioxide heat pump 2 includes an evaporator 21 , a compressor 22 , an air cooler 23 and a pressure reducing valve 24 . Process water at about 10-30° C. is fed into the evaporator 21 of the heat pump 2 . In the evaporator 21, the low-temperature and low-pressure two-phase carbon dioxide working medium absorbs the heat in the process water and becomes a low-temperature and low-pressure gas-phase carbon dioxide working medium, while the temperature of the process water in the evaporator 21 is reduced to 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com